how sheet metal parts are fabricated using nets The Working Principle. The working principle behind sheet metal fabrication is quite simple. It depends on the elasticity of the metal and the fact that cold-rolled metal performs better in terms of durability. Sheet metal . Install mud flap hole #11 & #12 to factory holes #2 & #3 using a sheet metal screw (d) and flat washer (g) 9. Place strip nut (r) behind factory holes #2 & #3 and fasten sheet metal screw (d) installed in previous step to strip nut (r).

0 · sheet metal parts design guide

1 · sheet metal manufacturing guide

2 · sheet metal fabrication process

3 · sheet metal fabrication materials

4 · sheet metal fabrication guide

5 · sheet metal construction materials

6 · joining sheet metal parts

7 · how does sheet metal work

The circle with two lines through it is the de facto North American standard electrical .

The use of nets offers several benefits in sheet metal fabrication, including: 1. Precision and accuracy : By providing a detailed 2D representation of the final component, nets ensure that the fabricated part will have the correct dimensions and fit seamlessly into the larger assembly.Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: Joining the Pieces. Step #6: Finishing Touches. Step #7: .

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with . Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost .

The Working Principle. The working principle behind sheet metal fabrication is quite simple. It depends on the elasticity of the metal and the fact that cold-rolled metal performs better in terms of durability. Sheet metal . This white paper explores the key components of sheet metal fabrication, ranging from the processes to materials, finishes, design tips, and more.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . Sheet metal fabrication is the process of transforming metal sheets into various shapes through cutting, bending, and assembling. It includes techniques like laser cutting, punching, stamping, and welding to create .

Step One – Design and Engineering: The process begins with detailed design and engineering. At CSM we work with clients closely to develop drawings and specifications that will deliver the best results in terms of cost, efficiency and .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a . 4 likes, 0 comments - aei_fabrication on November 16, 2024: "Use AEI Fabrication on your next run of parts. We are a high precision sheet metal manufacturing shop with industry leading customer service. If you would like a quote or have any questions about our shop capabilities, click the contact button on our profile or email [email protected] . Precision sheet metal fabrication accurately produces detailed and ready-to-use parts for prototype to high-volume manufacturing with exact measurements. . Precision sheet metal parts. Precision sheet metal fabrication process develops accurate metal parts. The process consists of design, the cutting of materials, forming, component joining .Franklin Sheet Metal has been delivering full-service metal fabrication in New England for nearly 70 years. We manufacture parts, products, structures and complete, turn-key assemblies using various metals and processes with .

Custom Sheet Metal Fabrication Supplier, Custom Welded Parts, Metal Frame Welding Manufacturers/ Suppliers - Hebei Decai Metal Products Co., Ltd. Menu . Custom Aluminium Stainless Steel Parts Sheet Metal Fabrication Laser Cutting Industrial Use, Custom Steel Aluminium Metal Sheet Bracket Welded Base and so on.

sheet metal bending fabrication parts manufacturers

sheet metal parts design guide

The International Organization for Standardization (ISO) provides globally recognized standards in sheet metal fabrication through ISO 2768-1:1989. It outlines general tolerances for various aspects of sheet metal parts, including: Linear Dimensions: This category includes tolerances based on the nominal length ranges in millimeters. There are .Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics.. It involves transforming flat sheets of metal into functional components and structures through cutting, .

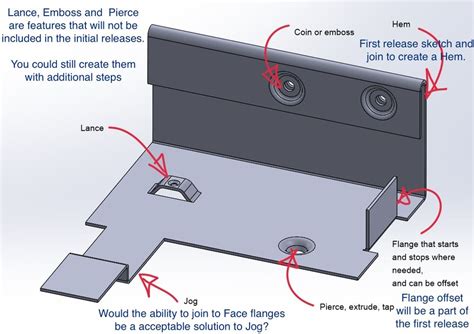

Sheet metal fabrication is a versatile and widely used manufacturing process that involves cutting, bending, shaping, and assembling metal sheets to create a variety of parts and components. One of the fascinating aspects of this process is the use of nets, which are essentially flat patterns of the desired component that can be easily folded .There are a variety of hardware options for different sheet metal fabricated parts. Choosing the best ones for your project should be considered. 9/2/2021. PDF File. Design. Packaging and Shipping Best Practices for Sheet Metal Fabricated Parts. A sheet metal tool development results from an ingenious use of a large number of manufacturing technologies, both using state-of-the-art automated processes and long-established metalwork, often .

Sheet metal fabrication and sheet metal forming are sometimes used interchangeably. However, while sheet metal forming specifically refers to the processes that shape flat sheet metal into 3D parts, sheet fabrication is a broader term that includes other processes like cutting and joining to create the final product.

We offer wide range of precision Laser Cutting Work Facility.We have in house available advance laser cutting machine. With our in house facility we are able to cut laser cutting upto 25 mm in mild steel, 16 mm in stainless steel, and 5 mm in aluminum / copper / brass Sheet size may vary to 4000 * 2000 mm.Locate sheet metal fabrication on IndustryNet. View a free list of sheet metal fabricators. Get quotes & information. . Self-sealing sheet metal HVAC component parts, spiral pipe & fittings, dust collection products, cleanrooms & HVAC contracting, including specialty fabrication & welding services . MNI reports Wisconsin manufacturers added .Highly Versatile: Sheet metal fabrication is used to fabricate a variety of components and parts like enclosures, boxes, ducts, and other specific parts. Durable: Sheet metal parts and components are efficient, robust, and corrosion-resistant, making them perfect for use in applications requiring strength and longevity.

Using these design formulas will ensure that your sheet metal parts are fabricated to your exact specifications. At this point, you may be thinking, “These design formulas are very complicated!” If so, don’t worry! As a precision sheet metal fabricator, we work with K-Factors and Bend Deductions on a daily basis to produce parts of the . What are the Stainless Steel Materials for Sheet Metal Fabrication? The stainless steel grades refer to the distinct compositions and properties of stainless steel alloys, made to suit various applications and .

Code: SPGC. Hardness: HRB, 1/2H = 74 to 89, 1/4H = 65 to 80, 1/8H = 50 to 71, H = above 89. Tensile Strength: Above 40-55 kgf/mm². Material Thickness: 0.4 to 3.2 mm. Materials thicker than 3.2 mm are difficult to find .

by using Petri nets and first‑order predicate logic. . sheet metal parts and material are calculated, denoted by . A s. . eling a general CAM workflo w of sheet metal fabrication for . Fig. 4: Sheet Metal Parts Fabrication Disadvantages of Sheet Metal Fabrication. While the benefits of sheet metal fabrication are clear, it's essential to recognize potential challenges. Understanding these drawbacks ensures informed decisions when considering sheet metal for a project. When compared to other manufacturing techniques, there are .

sheet metal manufacturing guide

The beginning of the sheet metal fabrication journey is marked by the critical design phase, which establishes the basis for the future production of a tangible metal item. It’s also important to mention that, according to Market Research , the global market for sheet metal fabrication services is expanding at a compound annual growth rate .A Complete Guide to Aerospace Metal Fabrication The aerospace industry has long depended on metal fabrication to produce reliable, precise components. The industry requires highly complex parts that are often not possible to build using traditional or .Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! . Customize a part template using our Parts Builder, or send a sketch to our Design Services team. Get instant pricing. Prices start from less than . Free shipping in the USA, .

3. Sheet metal, which acts as the workpiece in these processes, is one of the most common forms of raw material stock. The material thickness that classifies a workpiece as sheet metal is not clearly defined. However, sheet metal is generally considered to be a piece of stock between 0.006 and 0.25 inches thick. A piece of metal much thinner is considered to be "foil" . PBF fabricated stainless steel 316 L sheets and cold rolled sheet metal of same composition by the means of destructive testin g and microscopic analysis. Optical fiber diameter, l aser This provides incredible insight into how a part needs to be fixtured and produced. But when it comes to machine-agnostic software that does the same for sheet metal, the choices are likely few and far between, even nonexistent. For . Small Series Production and Geometric Analysis of Sheet Metal Car Body Parts Using Forming Tools Made of Fused Filament Fabricated PLA December 2020 DOI: 10.1109/IEEM45057.2020.9309936

Sheet Metal Fabrication Suppliers located in California - Southern. Register to continue. In less than a minute you'll have access to 500k+ Suppliers . lead, platinum, nickel, Nitinol®, Kovar®, and zirconium. Capable of fabricating parts up to 120 in. length, 60 in. width, and 1 to 50 ga. sizes. Secondary services include brazing, deburring . The fabricated parts should arrive in perfect condition based on several packaging and shipping practices. We have thus devised cost-effective ways to protect your parts. These ways reduce the chance of logistic damage on the property. Additionally, it supports the end user’s needs. Here is a highlight of what to consider while delivering .

sheet metal bend relief guidelines

What is the correct gauge sheet metal that should be used? The contractor says he will use 26 gauge for supply and return trunks, and 30 gauge for branch runs? Is this the standard gauges for these?

how sheet metal parts are fabricated using nets|sheet metal construction materials