bent metal sheet Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting .

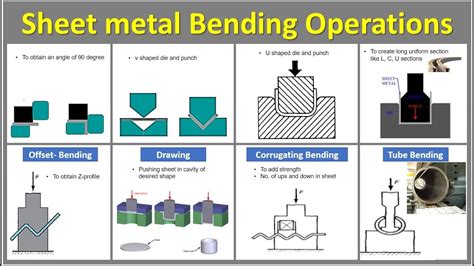

0 · types of bending sheet metal

1 · sheet metal cutting and bending

2 · sheet metal bending near me

3 · sheet metal bending dies

4 · maximum thickness sheet metal bending

5 · hand bending sheet metal

6 · bending tool for sheet metal

7 · bending galvanized sheet metal

Waterproof Junction Box, IP68 Outdoor Junction Box, 2 PCS 3 Way Plug Line External Junction Box, M25 Plastic Electrical Junction Box Suitable for Tunnel Lights, Garden Lights, Landscape Lights

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Let us look at the most common sheet metal bending methods: V-bending. This is the most fashionable way to bend sheet metal. We use an instrument called the punch and v-die to . Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .

Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with.

Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Learn how to bend sheet metal using different methods, such as V-bending, bottoming, air bending and coining. Find out how to calculate bend allowance, springback and k factor for your design.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Let us look at the most common sheet metal bending methods: V-bending. This is the most fashionable way to bend sheet metal. We use an instrument called the punch and v-die to bend the sheet metal at the angle we need. During the process, the bending punch pushes down on the sheet metal that is sitting on the V-die.

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry.

Below, we’ve outlined the basic materials and steps needed to bend metal for your own hobbies. Buy the Right Materials: To do the job correctly, you’ll need a vise, two form blocks (wood or metal), a calculator, protractor, tape measure, mallet, and something to write with.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Let us look at the most common sheet metal bending methods: V-bending. This is the most fashionable way to bend sheet metal. We use an instrument called the punch and v-die to bend the sheet metal at the angle we need. During the process, the bending punch pushes down on the sheet metal that is sitting on the V-die.

how to tell if junction box is fan rated

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with.

Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry.

types of bending sheet metal

how to start your own cnc machine shop

how to surface mount electrical box

how to stem from metal bracket

how to stop indonesian electric box from biping

Made with the highest quality metals, these ammo boxes are perfect for ammunition or long term storage. Built for toughness and endurance, the premium construction of these cans means that your belongings stay safe.

bent metal sheet|bending tool for sheet metal