wire insie metal juntion box One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing . The Oldcastle B1017 enclosure box is a cost effective solution for protecting underground components. The B1017 box is under our Christy® product line which is the preferred and trusted choice of the utility market for over 40 years.

0 · metal junction box wiring diagram

1 · metal junction box wire

2 · metal junction box installation

3 · metal junction box

4 · junction box wire size

5 · how to insert a junction box

6 · electrical junction boxes

7 · electrical junction box installation

Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks!

sheet metal hole punch die sets

metal junction box wiring diagram

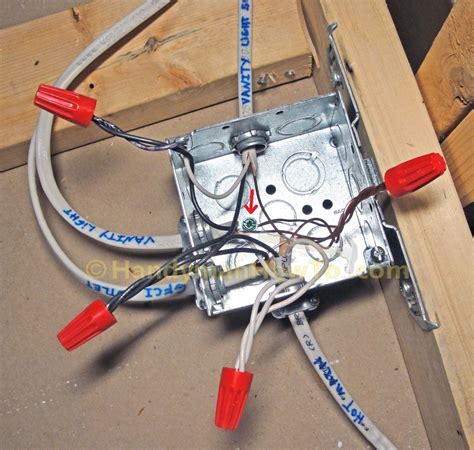

How to Install a Junction Box. A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one. by Chuck Bickford Updated 09/03/2024. Securing Cable With an Internal Clamp. Some metal boxes come with saddle-shaped clamps already mounted inside the box. Usually, there are . One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

metal junction box wire

What is the appropriate way to bond a metal junction box containing a receptacle wired with 6 AWG wire? It seems that most metal junction boxes .

How To Wire Junction Boxes. ElectricianToolDeals. 4K subscribers. Subscribed. 36. Share. 8.1K views 1 year ago. Nothing is more dangerous and aggravating than loose wires in a junction. Electrical - AC & DC - Can I leave a metal junction box inside a wall? - My guess is the answer is no. I have a switch housed in a one gang metal box supplied by conductors in armored cable. . but I think in that case I might be over my wire count for the 1 gang box. Upvote #13 02-26-19, 02:57 PM P .

Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be . My favorite Grounding technique for Grounding metal outlet-boxes with a Grounding wire is done using 1/4" fender-washers 1-1/4 " in diameter. I remove a 1/2 KO and assemble together 3 fender-washers and a 1/4' nut and bolt. 2 of the washers are inside the box and one washer on the outside.

You can also do most of the wire-mongering with the power on, and only turn off power for the final connection to the junction box (in case of this very type of situation). This, with AFCI breakers, and GFCI receptacles where appropriate, will make your house absolutely state-of-the-art in terms of electrical safety. at a job power went out in the living room so I thought maybe a breaker tripped. breaker was fine, I pulled all outlets in room out the wall, wiring was fine. I traced circuit to a junction box. Wires were burned and came apart. Why breaker didnt trip. and what causes a wire to melt that way. The old receptacles being replaced are enclosed inside metal junction boxes with copper ground wire attached via screw at the back of each box. Due to the fact that the metal junction boxes are grounded, and since I will be using the original wiring to make connections, will this have any impact, either negative or positive, when I replace the .The inside wiring is NM-B 6AWG cable that goes to a junction box where it's spliced to 6AWG direct bury cable (the NM-B wire I had wasn't long enough, so it was cheaper to splice). The splice was done with split bolts, wrapping 3M Temflex rubber splicing tape, then wrapped in .

Cable clamp inside junction box . . Assuming it's a metal box and romex cable, just use this. Slip it over the wire and shove it into the knockout. It will protect the wire from sharp edges and is better than nothing. . but it won't secure the wire in the box like it should be. The connections are made in the plastic boxes with wire nuts, just like in a regular metal box. I'm not really sure what you are referring to as wiring blocks. Blocks or terminal strips are not normally used in a simple j-box. 6/2 to 6/3 Junction box to extend wire. Ask Question Asked 4 years, 2 months ago. Modified 3 years, . Replacing grounded outlets with grounded metal junction box. 1. Understanding wires inside junction box. 3. How would I connect multiple ground wires in this case (replacing ceiling pendant lights)? 1. It is 10-32 thread because common metal boxes aren't thick enough to reliably hold a coarser thread from a larger bolt. Like the ones you'd need to use with the lugs you are recommending, which are made for larger wire than 6 ga. Given that space inside the box is at a premium, why not use parts made for that size of wire and bolt?

“Failing to make connections inside the electrical box is arguably the biggest mistake a homeowner can make, as this can result in major hazards.” Solution: Add a box. If you start a project and find a jumble of taped-together wires stuffed in the wall cavity instead of neatly contained in a junction box, don’t ignore it.That reduces the chances of the splice pulling apart. But, just in case it does, and the wires become exposed, the box is grounded. So, the live wires will hit that grounded box and the wire will see a near 0 ohm connection to ground, which will instantly flip the breaker, and reduce your chances of a fire to near zero. I have a metal junction box with a main feed. If the ground wires touch the metal box the breaker pops and the ground wires spark. . Used my voltage test light to determine. The cause had to be a pinched hot wire inside the metal box. I tightened the BX clamped too much. Inspected all wires and reinstalled. Box is grounded. Thank you very . Assume you have a metal device box, correctly installed with 14/3 cable incoming and a three-way ungrounded light switch installed. Assume that the box is correctly grounded using the ground wire attached to the ground screw of .

The AHJ said that this is not permitted and that i would need to run individual wires. I plan on installing a junction box on the top of the conduit where i will make the connections between the NM cabling and the individual THHN .

Junction Box Size. Junction boxes are sized according to how many wires they can hold—because, among other things, an overstuffed junction box is a fire hazard. The National Electrical Code has published a chart that . If circuit conductors are spliced within a box or terminated on equipment within or supported by a box, all equipment grounding conductor(s) associated with any of those circuit conductors shall be connected within the box or to the box with devices suitable for the use in accordance with 250.8 and 250.148(A) through (E).

Fig 1- Plastic and Metal Junction Boxes. The main purpose of the junction box is to protect the connections, which usually contain vulnerable points of contact. Which include wire splices, wire connections, live wires, ground wires, etc. . Overfilling a junction box with too many wires may lead to several issues such as overheating . I am using the remodeling cans with the metal junction box attached to the can assembly. I will have two, 3-wire 12 gauge cables coming into the junction box for each light. This is the typical wiring with shielding I see in construction. When I remove the knockout, the hole is quite sharp and I am fearing that over time, this could cut into . I want to remove one of the cables as I'm not using it. I don't have access to the back side of the box, because the ceiling is finished (metal lath and plaster). I'm thinking I could remove this a few different ways: twist the wires together, wire nut, and leave in the box; cut the exposed copper, and electrical tape the ends All the wire connections should be inside the electrical box. Exposed wires can electrocute someone. Ground the Electrical Boxes. When using metal electrical boxes, ground them properly using a bare copper wire. Accidently exposed wires might transfer electricity to the metal box. Too Many Wires. Never put too many wires inside the junction box .

Remove the cable back to the junction box where it originates from, or terminate it in an accessable junction box with a cover. . There's no NEC requirement that the end of an abandoned cable, energized or not, be inside a junction box. You can tape or wire nut it off and stuff it inside the wall, if you want to, and that's legal. For metal junction boxes, a high-speed steel (HSS) or cobalt drill bit is recommended. . Accidentally drilling into a wire inside the junction box can be dangerous and may result in electrical shock or fire. If this happens, the first step is to immediately turn off the power supply to the box to minimize the risk. Next, carefully remove the .

metal junction box installation

My light needs a junction box behind it to connect the wires to NM cable inside the garage. Since the mounting block is solid, I can imagine routing (not cutting) an octagon into it to insert a very shallow junction box, or I can imagine cutting an octagon all the way through the wall to insert a deeper junction box.

metal junction box

Note the threaded entrance and locknut in the bottom right, along with the lack of any ground wires in the box -- that's a dead giveaway that this was done in metal conduit. Since the box is grounded through the conduit (which is as good a ground conductor as any), you don't even have to terminate the ground wire to the box as long as the Z . I reside in CT - Anyone know if I can run my indoor Romex wire through house wall into a metal junction box? From there I'll run Schedule 40 with THHN wire out to endpoints. Core question here is - Can I run Romex through house wall into waterproof junction box mounted on outside wall and still fall within code? Thanks in advance.

sheet metal hem radius

sheet metal hand forging and welding

Just ordered a Hobart 140 and need to choose solid wire. I have an 80cf bottle being hydro'd, revalved and filled with ArCo2 75-25. Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks!Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

wire insie metal juntion box|electrical junction box installation