sheet metal gusset design guidelines DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief . Give Metal Fabrication Albuquerque a call right now to discover precisely how we .

0 · sheet metal practice drawings pdf

1 · sheet metal fabrication handbook pdf

2 · sheet metal design practice pdf

3 · sheet metal design guidelines pdf

4 · sheet metal design calculations pdf

5 · sheet metal bending guide pdf

6 · sheet metal bending chart

7 · sheet metal basic design guidelines

Welding refers to the process of joining metal pieces together using pressure and heat. Although it’s just a step in the larger metal fabrication process, welding requires a lot of effort. There are two main types of welding: fusion and solid-state.

dawn steel sink cabinet review

sheet metal practice drawings pdf

DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief .In this issue, we cover design guidelines that can help optimize features such as gussets and extruded holes in a sheet metal forming process. Specific guidelines such as Minimum . Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.

sheet metal fabrication handbook pdf

Learn how to design good sheet metal parts for press bending with material selection, bend radius, hole diameter, grain orientation, and other guidelines. See examples and formulas for .

Sheet metal DFM - design guidelines for formed and punched parts. A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s .These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Basic Principles

Design Guidelines; Gauge Chart; Sheet Metal Gusset. Sheet metal gussets are formed with special tooling which has a ridge going across the v opening. The punch is split to the left and right of the ridge as to not be damaged while .Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. From consumer electronics, to medical devices, and obviously .

First, we start with a sheet metal part requiring a gusset. Note: this part is 12ga (.1046) material and this also appears in the form tool part, these need to match. Second, we'll drag the form tool from the Design Library and .Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. (6.35mm).The guidelines for ribs (covered above) also apply to gussets. Keep the following in mind when designing gussets: i. The thickness of the gusset where it intersects with a nominal wall should be half the nominal wall thickness. ii. The length of your gusset can range from 0.3 to 1 times the height of the gusset. iii. Sheet metal design.pptx - Download as a PDF or view online for free . (0.06 inch), whichever is greater. Gussets The width and depth, recommended at an angle of 45 degrees, is directly proportional to the radius and material thickness. The minimum distance that a gusset should be from the edge of a hole in a parallel plane is eight times the .

Search for jobs related to Sheet metal gusset design guidelines or hire on the world's largest freelancing marketplace with 24m+ jobs. It's free to sign up and bid on jobs.Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge 6 Sheet Stock Sizes and Gauge Lookup Chart 7 Stock Material Thickness Tolerances 8 Quoting Formats: 3D CAD and DXF FilesDFMPro for Sheet Metal Design Guidelines. DFMPro provides pre-configured design guidelines DFM rules for design which helps to develop better quality parts at reduced cost. Some of the common sheet metal design guidelines included are minimum distance between holes, cutouts, slots, distance between holes, cutouts, slots to part edge and bends, multiple bends in same . To stiffen a part made from sheet metal, you can use several techniques: Adding Flanges or Lips: Bending the edges of the sheet metal to form flanges or lips increases the rigidity of the part. Beads or Embossments: Incorporating beads or embossments into the design adds stiffness without significantly increasing weight.

HCL Definitive Guide to DFM Success Sheet Metal Design Guidelines - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Common sheet metal design guidelines explained in 5 minutes. Some of .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. Sheet metal parts are also known for their durability, which makes them 1. Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the correct material selection have an important impact on product cost, product performance, product quality, and processability.. Selection .

A sheet metal gusset is an indented feature that forms a gusset to stiffen a bend in sheet metal part. Rather than using a custom-made forming tool, SOLIDWORKS includes a Sheet Metal Gusset tool. In this tutorial, we'll take a .

One and a half inch spacing center to center 5/16 width of the gusset and then add material thickness to get the outside width of the gusset. The tooling c. Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines and structures from various raw materials. This guide will help you to understand sheet metal product design tips and fabrication techniques. Metal. Metalworking

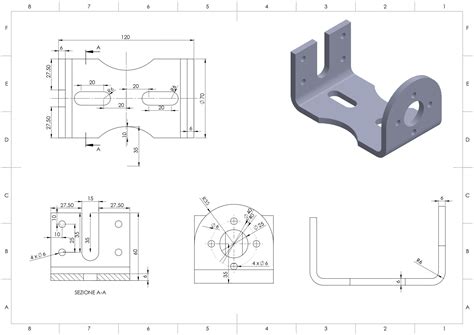

The problem definition included producing guidelines regarding the two manufacturing methods of sheet metal: bending and pressing. The guidelines were designed to aid, mainly novice, design engineers in early stages of component development. .geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, Sheet metal gussets are provided to avoid unbending the Sheet metal part under load conditions.In this video, we will learn how to design a gusset in Creo pa.The document provides design guidelines for sheet metal parts, including guidelines for bends, countersinks, curls, dimples, embossments, extruded holes, gussets, hems, holes/slots, lances/louvers, notches/reliefs, welding, and plating. Key recommendations include minimum bend radii and flange lengths, distances between features, maximum depths or widths for .

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. Search Now. . Minimum Distance Guidelines* Between gusset and edge: ±8 x material thickness + radius of the gusset:The document provides guidelines for various features in sheet metal design including bends, countersinks, curls, dimples, embossments, extruded holes, flanges, gussets, hems, holes, lances, notches, ribs, semi-pierced holes, slots, tabs, welding, and plating. It specifies minimum and maximum dimensions, distances between features, and other design considerations to .

sheet metal design practice pdf

Solid Edge ST4 Training Sheet metal design. Solid Edge ST4 Training Sheet metal design. Sheet Metal. Course overview The Solid Edge Sheet Metal application is specialized for modeling straight brake sheet metal parts. Once you complete the activities in this course, you will be able to: 1.2k views • 68 slides

sheet metal design guidelines pdf

Last updated on January 29th, 2024 at 12:53 pm. At Approved Sheet Metal, our sheet metal fabrication experts fabricate brackets for product developers across the country that design for a broad range of commercial, and military applications. In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore .Comparing Sheet Metal Design Methods: Using Sheet Metal Tools: Examination of the FeatureManager Design Tree: Sheet Metal PropertyManagers: Base Flange/Tab: Insert Bends: . Use the Sheet Metal Gusset PropertyManager to create sheet metal gussets with specific indents across bends. To open the Sheet Metal Gusset PropertyManager, . In the original design, the sheet metal required two separate bending processes. However, in the improved design, the sheet metal only needs one bending process to form the two sides at the same time. It is important to keep in mind that the more complex the bending process for the sheet metal, the higher the amount of material waste that may .

dayz repair sheet metal

death metal box sets

Welder Resume with 7 Years of Experience. A dedicated and experienced welder with 7 years of experience in welding, fabrication and metalworking. Skilled in multiple welding processes, such as MIG, TIG and Arc. Experience in reading and interpreting technical drawings, schematics and .

sheet metal gusset design guidelines|sheet metal basic design guidelines