easiest way to remove cnc part tit Just a hole the part dropped into and a bit of tool steel mounted in a lever sliding over the end; like a little guillotine. But it always leaves a little trace so if the end has to be . Hot Coral Premium Cotton Quilting Solids Fabric is backordered and will ship as soon as it is back in stock. -Solid Dark Coral Superior Quality Cotton Broadcloth Fabric - 100% Cotton

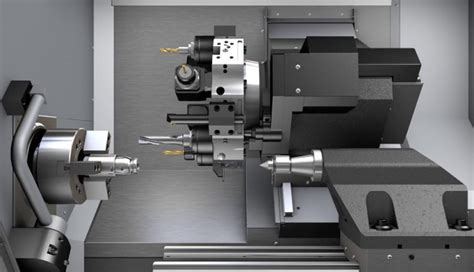

0 · lathe cut off cnc

1 · how to remove part off nub

2 · how to remove lathe nub

3 · cnc nub replacement

4 · cnc nub removal

5 · cnc machining cut off

6 · cnc lathe removal

7 · best way to remove nub

$12.50

You are getting the tit on the piece that has been parted off, not the stock left in the chuck? Use a cutoff tool that cuts on the finished part side first (assuming chuck on your left, would be a right hand tool) to minimize the tit. You are going to have some tit irregardless. Have you tried a parting insert with a righthand angle? These do great for minimizing the nub, but not completely get rid of it. This is why we have sub-spindle machines. You can . Just a hole the part dropped into and a bit of tool steel mounted in a lever sliding over the end; like a little guillotine. But it always leaves a little trace so if the end has to be .

Your Height of your tool is off, and depending on what CNC lathe you are using, it may be as easy as adding on to your Y axis. Make sure that your holder is squared in, that's the first biggest .It's called a "tit", make a fixture to hold it and rub it on some emery paper. bench grinder or belt sander may be too aggressive. (its a small part, could do 4 at a time.) Or, put an angle on the . Slowing the feed down and using an angled cutoff tool vs. a straight or flat one can help to minimize the 'tit" but I haven't found a way to eliminate it. Maybe some of you screw .

One of the crucial steps in utilizing a CNC lathe is understanding how to part off, a process through which the workpiece is separated from the main stock. Parting off can be a .Use a ID groover and start parting off the part from the inside, but only go about half way. Use the same tool to make a rad/chamfer on the inside. Then use OD partoff and cut the part.

Slowing the feed down and using an angled cutoff tool vs. a straight or flat one can help to minimize the 'tit" but I haven't found a way to eliminate it. Maybe some of you screw machine . In this series, we will discuss various challenges, tips and tricks to make your parting off applications more productive and trouble free. This is the second of five posts . You are getting the tit on the piece that has been parted off, not the stock left in the chuck? Use a cutoff tool that cuts on the finished part side first (assuming chuck on your left, would be a right hand tool) to minimize the tit. You are going to have some tit irregardless.

lathe cut off cnc

Have you tried a parting insert with a righthand angle? These do great for minimizing the nub, but not completely get rid of it. This is why we have sub-spindle machines. You can remove it from one side fairly easily by choosing an insert with a slight lead angle. GTx and GFx inserts are available with 4 or 8 degree, left or right, leads. Just a hole the part dropped into and a bit of tool steel mounted in a lever sliding over the end; like a little guillotine. But it always leaves a little trace so if the end has to be dead flat something else is needed. Your Height of your tool is off, and depending on what CNC lathe you are using, it may be as easy as adding on to your Y axis. Make sure that your holder is squared in, that's the first biggest step, then make sure your tool doesn't need to be shimmed. It's called a "tit", make a fixture to hold it and rub it on some emery paper. bench grinder or belt sander may be too aggressive. (its a small part, could do 4 at a time.) Or, put an angle on the part off tool to break the part free before the tit breaks off.

Slowing the feed down and using an angled cutoff tool vs. a straight or flat one can help to minimize the 'tit" but I haven't found a way to eliminate it. Maybe some of you screw machine guys can help out. One of the crucial steps in utilizing a CNC lathe is understanding how to part off, a process through which the workpiece is separated from the main stock. Parting off can be a delicate task, requiring careful attention to detail and proper techniques to .

Use a ID groover and start parting off the part from the inside, but only go about half way. Use the same tool to make a rad/chamfer on the inside. Then use OD partoff and cut the part.

Slowing the feed down and using an angled cutoff tool vs. a straight or flat one can help to minimize the 'tit" but I haven't found a way to eliminate it. Maybe some of you screw machine guys can help out. In this series, we will discuss various challenges, tips and tricks to make your parting off applications more productive and trouble free. This is the second of five posts relating to basic principles, best practices and troubleshooting of parting off operations. You are getting the tit on the piece that has been parted off, not the stock left in the chuck? Use a cutoff tool that cuts on the finished part side first (assuming chuck on your left, would be a right hand tool) to minimize the tit. You are going to have some tit irregardless.

Have you tried a parting insert with a righthand angle? These do great for minimizing the nub, but not completely get rid of it. This is why we have sub-spindle machines. You can remove it from one side fairly easily by choosing an insert with a slight lead angle. GTx and GFx inserts are available with 4 or 8 degree, left or right, leads. Just a hole the part dropped into and a bit of tool steel mounted in a lever sliding over the end; like a little guillotine. But it always leaves a little trace so if the end has to be dead flat something else is needed.

Your Height of your tool is off, and depending on what CNC lathe you are using, it may be as easy as adding on to your Y axis. Make sure that your holder is squared in, that's the first biggest step, then make sure your tool doesn't need to be shimmed. It's called a "tit", make a fixture to hold it and rub it on some emery paper. bench grinder or belt sander may be too aggressive. (its a small part, could do 4 at a time.) Or, put an angle on the part off tool to break the part free before the tit breaks off.

how to remove part off nub

Slowing the feed down and using an angled cutoff tool vs. a straight or flat one can help to minimize the 'tit" but I haven't found a way to eliminate it. Maybe some of you screw machine guys can help out. One of the crucial steps in utilizing a CNC lathe is understanding how to part off, a process through which the workpiece is separated from the main stock. Parting off can be a delicate task, requiring careful attention to detail and proper techniques to .Use a ID groover and start parting off the part from the inside, but only go about half way. Use the same tool to make a rad/chamfer on the inside. Then use OD partoff and cut the part.Slowing the feed down and using an angled cutoff tool vs. a straight or flat one can help to minimize the 'tit" but I haven't found a way to eliminate it. Maybe some of you screw machine guys can help out.

copper sheet metal gauge thickness

copper sheet metal canada

This Tins item is sold by FromTheSeller. Ships from Cedarburg, WI. Listed on Jul 1, 2024

easiest way to remove cnc part tit|lathe cut off cnc