metal fabrication how it works Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added [1] process involving the creation of machines, parts, and structures from various raw materials. Typically, a . Central Junction box sent to "Module Experts" for Inspection / Repair. They found fried wiring on the board and are currently "assembling" a replacement from used parts. This has been a 6-month process.Piercing is mostly done in sheet metal parts to increase the threading area for self-tapping screws. To sum up, Punching blanking and piercing are sheet metal shearing operations to modify existing blank.

0 · types of metal fabrication processes

1 · steel fabrication work near me

2 · special metal fabricating

3 · metal works website

4 · metal fabrication process flow chart

5 · manufacture of fabricated metal products

6 · fabrication work website

7 · fabricated metal product manufacturing companies

Metallic fiber is manufactured fiber composed of metal, plastic-coated metal, metal-coated plastic, or a core completely covered by metal. These are light weight and relatively inexpensive yarns.

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .

Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves . Metal fabrication serves the important purpose of giving metal components their desired shape. All fabrication processes perform some operations on raw materials to convert .

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added [1] process involving the creation of machines, parts, and structures from various raw materials. Typically, a . In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. You can produce quality fabricated parts from your shop by understanding the basics.

Metal fabrication is a manufacturing process that shapes raw metal into structures via cutting, bending, and assembling techniques. Metal fabricators are referred to as fab shops. Fabricators and machine shops are . Different projects require different approaches. Here are some of the most common methods used in the steel fabrication process: Cutting is the preliminary and pivotal .

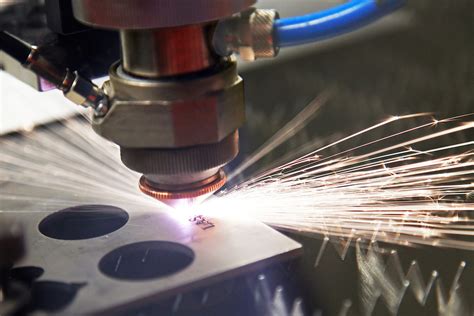

At its core, sheet metal fabrication involves cutting, bending, and assembling it into the desired shape. Depending on the design’s complexity and production volume, various techniques can be employed, from laser cutting and welding .

Custom Metal Fabrication Online: How Does It Work? We all are quite familiar with the idea of DIY projects and custom metal fabrication. For all those who love trying their hands on DIY projects, MetalsCut4U.com is one . For decades, metal fabricators have equated productivity to effort—how to get more parts per hour out of a press brake or cut faster with an ultrahigh-powered fiber laser. Still, “focused effort” is last on Meyer’s list; “commitment to excellence” and “intelligent planning” come before it—for good reason.From size to color to material, our state-of-the-art fabrication shop has endless opportunities for you to achieve all your custom printing, cutting, and finishing needs! In observance of Labor Day, local pickup and customer support will be . Metal fabrication is the art of turning raw metal materials into functional and often beautiful structures or components. It’s like the Cinderella story of the manufacturing world, where a simple hunk of metal is transformed into a shining star, ready to .

FAB402 is a metal fabrication shop located in Lincoln, NE. Contact our fabrication shop for metalwork and custom metal fabrication services. Skip to content. Call Today: 402-413-2183. Home; . How it Works: You Have a Project. If your business has a need for our metal fabrication services, contact us with specifications, designs and requirements.

carlon 1 gang old work electrical box

types of metal fabrication processes

Both SLM and DMLS are used in industrial applications to create end-use engineering products. In this article, we use the term metal 3D printing to refer to both processes in general and we describe the basic mechanisms of the fabrication process that are necessary for engineers and designers to understand the benefits and limitations of the technology.Spot welding is an integral part of the fabrication process for metal components. It is fast, cost-effective, and widely used across many industries, including automotive, home appliance, and more. . It works effectively because the laser beam can target a specific point. It can also weld material without significant heat distortion outside .

Metal fabrication is a common term, yet very few people understand how it works. This article will analyze different aspects of metal fabrication and educate readers about its working methodology. By the end of this write-up, you'll have a better idea of how this process works and how many diverse aspects it entails. But, before that, let's first understand the .We show you how sheet metal fabrication works, from the basics to the process, and more in our quick guide! The Fundamentals of Sheet Metal Fabrication. To understand sheet metal fabrication, you should grasp what sheet metal is. This flat metal piece can vary in thickness depending on the application. Typically, sheets include steel, aluminum . Sheet metal fabrication is the process of forming, cutting, and assembling metal sheets into functional products. It involves several stages including cutting, bending, and joining. The versatility of sheet metal allows for the creation of a wide range of products, from small components to large structures.

This is a video on how to operate an electric over hydraulic Metal cutting guillotine. How it works and what it can cut!#fabrication #tools #tooltips #cuttin.

How does Metal 3D Printing work? What is it ? What methods of 3D metal printing are in use today?, and more subjects will be seen in this video about 3d prin.Here at Cardinal MetalWorks LLC, we take pride in leading the field of custom metal fabrication. Our 70-plus years in the business have made us a top metal parts manufacturer supporting many different industries. The ISO 9001:2015 certification we hold shows how much we care about making high-quality metal parts. In the U.S., metal fabricators work in industries that produce everything from architectural and structural materials to boilers, tanks, shipping containers, hardware elements, cutlery and hand tools. When any metal .

Sheet metal fabrication is shaping metal using various tools and machines. Versatility. It can create various products, from car parts to kitchen appliances. Speed. Sheet metal fabrication is a relatively fast process, which .Sheet metal fabricators can work with various metals, including steel, aluminum, and copper, to accommodate different project needs. Precision and Accuracy: Skilled sheet metal fabricators use advanced machinery and techniques to .

Choosing the right alloy is crucial in metal fabrication, affecting durability, appearance, and functionality. Discover how different metals like stainless steel, aluminum, and Corten steel are tailored for specific projects to ensure long-lasting, impactful designs. Choosing the right material is crucial especially in the field of metal fabrication. The material chosen for production affects .

You are starting or running your business because you love doing metal fabrication. Seriously, if you don’t love the work, you probably need to find a new industry. Let’s say, however, that you inherited the family business and you feel an obligation to keep it running. If you don’t currently love fabrication, then learn to love it. In .Our mission at Forgedweld is simple: to provide high-quality custom metal fabrication services in Leonardtown for each of our valued clients. Our team of expert metalworking professionals goes above and beyond every customer’s expectations to cater to each project’s specific needs.

steel fabrication work near me

I highly recommend Built By Steele. Work is done with precision. No shortcuts. No loose ends. Just pure quality. I am just a hobbyist, clearly not a commercial craftsman. So my projects are small. But I appreciate being treated as though my work carries the same importance to BBS as a commercial entity undoubtedly receives." -Carl Hauser Sheet metal fabrication is the technology of transforming sheet metal into parts of various shapes and structures through a series of processing processes. . The process works by spraying metal powder with high-pressure gas onto the surface of the substrate, causing it to melt at high temperatures and form a strong coating. Metal 3D printing works by fusing metal particles using high temperatures derived from lasers or electron beams. The process creates metal objects by sintering, melting, or welding layers of metal or metal powder until a part is complete. . For those looking to push the boundaries of what’s possible in metal fabrication, adopting .

We specialize in metal fabrication, metal work, and stainless steel fabrication in Singapore for industrial and commercial purposes. [email protected] +65 6980 3512 This metal fabrication process works by manipulating metal to bend at an angle. The most common means is with a brake press that creates creases in the metal by pinching it. The workpiece is held between a punch and a die, and forced to crease with pressure from the punch. This process is usually used to shape sheet metal.Metal Works, Inc. has delivered high-quality precision sheet metal fabrication, finishing, and assembly services for over 35 years. Learn more. Skip to content. Precision Sheet Metal Fabrication, Machining, Finishing, and Assembly +1 603-669-6180; Get A Quote; How does Metal Fabrication work? Metal fabrication is a complex and nuanced process, essential in transforming raw metal into functional and aesthetic products. You, as an enthusiast or a professional in the industry, might be intrigued by the intricacies of how a simple metal sheet transforms into a sophisticated product. This process involves .

carlon electrical box high pitched noise

As Tucson Electric Power replaces wooden utility poles with more durable steel structures, the obsolete husks of wood pop up in other spots around town.

metal fabrication how it works|fabrication work website