can we do additive manufacturing in cnc machine For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal . Discover Company Info on TROY METAL FABRICATING, LLC in Troy, MI, such as Contacts, Addresses, Reviews, and Registered Agent.

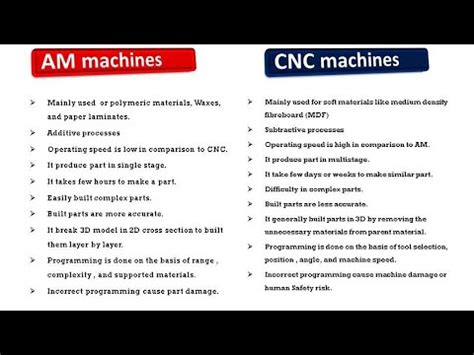

0 · difference between cnc and am

1 · cnc machining vs am

2 · cnc machining additive powder

3 · additive manufacturing vs cnc

4 · additive manufacturing subtractive

5 · additive manufacturing services

6 · 3d printing vs additive manufacturing

In a septic environment, no other material can match High Density Polyethylene in delivering a lifetime of trouble-free service. Tuf-Tite Distribution Boxes are injection molded, using only premium HDPE which contains no fillers or foam. Snap-in Pipe Seals. They’re patented.

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal .

Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop. When additive manufacturing (AM) is applied in a precision turned parts machine shop it has .

difference between cnc and am

cnc machining vs am

Within the last decade, augmented CNCs with additive, subtractive, and/or inspection capabilities have emerged. The Peter Parker proverb, “With great power comes great responsibility” can . Additive manufacturing (AM) and CNC machining fulfill different needs in the manufacturing industry. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an .Can Additive Manufacturing and CNC Machining be used together? Yes, the convergence of Additive Manufacturing and CNC Machining offers a hybrid manufacturing solution. This allows for improved efficiency, flexibility, and the .This blog post seeks to explore the question, "Can we do additive manufacturing in CNC machines?" We'll delve into the key differences between these technologies, their current .

A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining.Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools Additive manufacturing is great for initial design phases of parts and products, along with rapid prototyping of finished designs. The low cost and availability of materials as well as the ability to introduce last-minute design . CNC Machining as a Business Strategy for Additive Manufacturing As 3rd Dimension Industrial 3D Printing ramps up for production — including a fleet of new 3D printers in a custom-designed building — it's the company's .

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines. Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop. When additive manufacturing (AM) is applied in a precision turned parts machine shop it has been most commonly used to create tooling, fixtures and prototypes with polymer materials.Within the last decade, augmented CNCs with additive, subtractive, and/or inspection capabilities have emerged. The Peter Parker proverb, “With great power comes great responsibility” can be applied to the emerging class of hybrid CNC machines.

Additive manufacturing (AM) and CNC machining fulfill different needs in the manufacturing industry. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final piece.Can Additive Manufacturing and CNC Machining be used together? Yes, the convergence of Additive Manufacturing and CNC Machining offers a hybrid manufacturing solution. This allows for improved efficiency, flexibility, and the production of complex parts.This blog post seeks to explore the question, "Can we do additive manufacturing in CNC machines?" We'll delve into the key differences between these technologies, their current limitations, and how they could potentially be combined for a .

A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining.Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools Additive manufacturing is great for initial design phases of parts and products, along with rapid prototyping of finished designs. The low cost and availability of materials as well as the ability to introduce last-minute design changes benefit any production process, even those involving CNC machining. CNC Machining as a Business Strategy for Additive Manufacturing As 3rd Dimension Industrial 3D Printing ramps up for production — including a fleet of new 3D printers in a custom-designed building — it's the company's traditional machining capabilities that provide a unique competitive advantage.

cnc machining additive powder

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines. Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop. When additive manufacturing (AM) is applied in a precision turned parts machine shop it has been most commonly used to create tooling, fixtures and prototypes with polymer materials.Within the last decade, augmented CNCs with additive, subtractive, and/or inspection capabilities have emerged. The Peter Parker proverb, “With great power comes great responsibility” can be applied to the emerging class of hybrid CNC machines. Additive manufacturing (AM) and CNC machining fulfill different needs in the manufacturing industry. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final piece.

Can Additive Manufacturing and CNC Machining be used together? Yes, the convergence of Additive Manufacturing and CNC Machining offers a hybrid manufacturing solution. This allows for improved efficiency, flexibility, and the production of complex parts.This blog post seeks to explore the question, "Can we do additive manufacturing in CNC machines?" We'll delve into the key differences between these technologies, their current limitations, and how they could potentially be combined for a .

A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining.

Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools Additive manufacturing is great for initial design phases of parts and products, along with rapid prototyping of finished designs. The low cost and availability of materials as well as the ability to introduce last-minute design changes benefit any production process, even those involving CNC machining.

additive manufacturing vs cnc

additive manufacturing subtractive

additive manufacturing services

3d printing vs additive manufacturing

Long stroke type basic machine Realizes machining of large workpieces by extending the X-axis stroke. Extends machining capacity with 500mm-machining length (M08JL5L-Ⅱ). Great cutting capability realizes high productivity. Programs can be created easily with on-board conversational programming software (FANUC: TURN MATE i) (Option).

can we do additive manufacturing in cnc machine|difference between cnc and am