axis in cnc machines Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, . Tuf-Tite 4-Hole Distribution Box comes complete with a lid and your choice of 4 Pipe Seals. Enter the list of your 4 included seals in order notes during check out. Additional seals available for purchase.

0 · cnc with rotary axis

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

Tuf-Tite, Septic, Riser, Trench Drain, Vent Stack, Drainage, Effluent Filters. .

cnc with rotary axis

dial electrical connection box

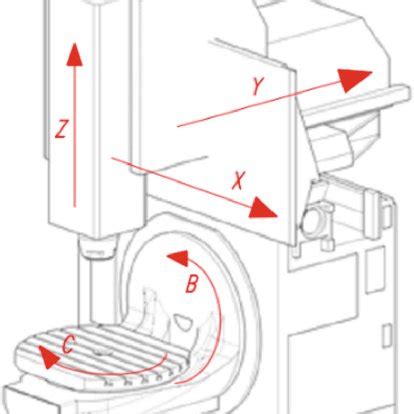

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis . Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool . Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, .

CNC lathes are amazing machines that turn raw materials like metal into precision components. The magic happens through a process called CNC turning. This involves the cutting tool .

All machines start with three axes. The three axes model performs essential functions and, in the hands of an experienced machinist, can be used for more advanced creations. Four axes on a CNC machine add an extra . In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers. CNC (Computer Numerical Control) machines utilize multiple axes to perform precise cutting and shaping operations. The number of axes directly influences the machine’s ability to manipulate the workpiece, the complexity of . Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether .

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece.

cnc machine axis locations diagram

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .CNC lathes are amazing machines that turn raw materials like metal into precision components. The magic happens through a process called CNC turning. This involves the cutting tool moving in different directions—known as axes—to shape the material exactly how you need it. Understanding how many axes a CNC lathe has is important. All machines start with three axes. The three axes model performs essential functions and, in the hands of an experienced machinist, can be used for more advanced creations. Four axes on a CNC machine add an extra cutting direction, which increases precision. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

CNC (Computer Numerical Control) machines utilize multiple axes to perform precise cutting and shaping operations. The number of axes directly influences the machine’s ability to manipulate the workpiece, the complexity of parts it .

Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece. Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .

CNC lathes are amazing machines that turn raw materials like metal into precision components. The magic happens through a process called CNC turning. This involves the cutting tool moving in different directions—known as axes—to shape the material exactly how you need it. Understanding how many axes a CNC lathe has is important. All machines start with three axes. The three axes model performs essential functions and, in the hands of an experienced machinist, can be used for more advanced creations. Four axes on a CNC machine add an extra cutting direction, which increases precision.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers. CNC (Computer Numerical Control) machines utilize multiple axes to perform precise cutting and shaping operations. The number of axes directly influences the machine’s ability to manipulate the workpiece, the complexity of parts it .

Boxes are available in either steel or aluminum and colors that complement any truck body body paint. Lowe’s carries top name brands you trust like Weather Guard tool boxes. Make your decision with confidence, knowing there's a truck bed tool box in the specific shape, size, color and mount for your needs.

axis in cnc machines|cnc with rotary axis