cnc milling machine parts and function 2. COMPUTER NUMERICAL CONTROL(CNC) INTRODUCTION Computer numerical control CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded . A plastic back box or pattress box is a moulded plastic box normally made of either PVC or resin that is fixed to the surface of a wall so that an electrical socket, light switch, fused connection unit etc. front plate can be screwed to it .

0 · schematic diagram of cnc machine

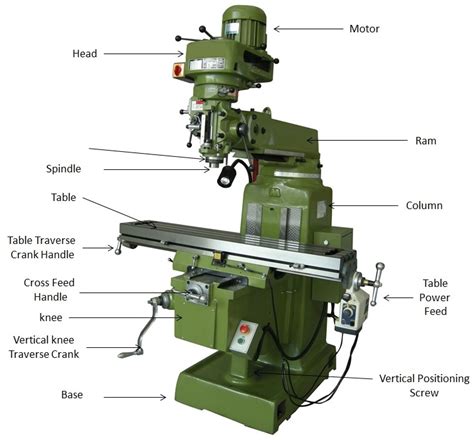

1 · milling machine parts list

2 · cnc milling machine diagram

3 · cnc machine parts list pdf

4 · cnc machine parts diagram

5 · cnc lathe parts diagram

6 · block diagram of nc machine

7 · block diagram of cnc machine

A Smart Junction Box (SJB) is an electronic component found in Ford vehicles that serves as a central hub for controlling and distributing electrical power to various systems and components within the vehicle.

In this article, I have covered the standard CNC milling parts, tools commonly used with the machine, factors affecting the cost of a CNC mill, and how CNC machining works. I hope that you’ve got the basics of this important . Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine .

The main parts include the base, column, knee, saddle, table, spindle, and cutting tools. The base provides a sturdy foundation for the entire machine, while the column supports the knee and houses the drive . 2. COMPUTER NUMERICAL CONTROL(CNC) INTRODUCTION Computer numerical control CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded .Notable aspects of CNC milling machines: CNC Technology: Automated processes driven by computer programs. Precision: High accuracy in creating complex and delicate components. Efficiency: Capable of running 24/7, increasing productivity. Universal Milling Machines. Universal milling machines combine the capabilities of both vertical and .

Tolerances are specified to ensure that CNC machined parts meet design requirements and function correctly in their intended applications. They are typically expressed as a permissible deviation from a specified dimension, . The development of CNC machine tools started in the United States. In 1948, Parsons Co. had a preliminary idea to develop a CNC machine tool while working on a project to create a machine tool for processing the inspection template for helicopter blade profiles. The following year, with support from the United States Air Force Logistics Department, Parsons .

The saddle in milling machines plays a significant role in various milling machine processes. It offers essential functions that contribute to the overall efficiency and accuracy of the milling process. Let’s take a closer look at the key roles and uses of the saddle in milling machines. Precise Positioning and Feeding of the Workpiece

Auxiliary functions related to machine operations control several critical aspects of CNC machines, such as spindle rotation, gear range changes, automatic tool changes, coolant operations, and movement of tailstocks or quills. These functions ensure that the CNC machine performs its tasks accurately and efficiently. Common Machine Operation M . Understanding the components of a CNC milling machine is essential for operators, engineers, and anyone involved in the manufacturing process. In this article, we'll explore the key parts that make up a CNC milling machine and their functions. What Are the Essential Parts of a CNC Milling Machine? The essential. CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.

That being said, every CNC milling machine will have some basic components to perform the device’s primary function. This article takes a quick stab at the basic parts of a CNC milling machine, their function, and their possible location. In no particular order, here is a rundown of the standard and most common parts of a CNC milling machine .

Parts of CNC Machine + Function – Some significant components and elements that contribute to the machine’s efficacy are present in machine tools with CNC systems. Before utilizing any CNC machine, one must be familiar with the control code, according to a previous post. We have looked at two G-codes and two M-codes. The control functions of CNC-run mills and lathes are similar, with the programming language often being G-Code. . With their ability to produce highly precise and custom-made parts, CNC machines play a crucial role in ensuring the quality and effectiveness of medical devices. . With a wide range of CNC milling machines, we offer top-notch .What is a CNC milling machine? Machine parts, types, and milling terminologies. A CNC milling machine is simply a computer-controlled milling machine. To understand how a CNC milling machine works, it is essential to understand the parts that comprise the machine and their functions. While a wide variety of CNC milling machine types exist, they . CNC Milling Machine Parts. There are various types of milling machines with a variety of particular functions based on certain specifications. Each machine contains a cutter that can be operated at a various range of speed in order to form the required shape. Computer Numerical Control (CNC) Milling Machines are also available in different sizes.

Understanding the Function of a Spindle in CNC Milling. The spindle is one of the most important parts of a CNC milling machine that provides power to maneuver and cut material. It consists basically of a rotary shaft, which is driven by an electric motor that rotates at high-speed giving torque for effective interaction with the workpiece .

The function of the tool changer in CNC milling is to automate the process of switching between different cutting tools as required by the machining operations. This system significantly enhances productivity by reducing . Defining the CNC Machine Parts. The following are the fundamental parts of a CNC machine:. Control Panel: It is the mind of this computer numerical control machine that has been used to input instructions . Understanding these parts and their functions is crucial for efficient and safe operation of a milling machine. The milling machine is a powerful tool used for cutting and shaping metals. Understanding the anatomy and .

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.

Welcome to a fascinating journey into the inner workings of CNC machines! In this article, we will take a detailed look at the anatomy of a CNC machine, exploring its main parts and functions. Whether you are a seasoned CNC operator or someone new to

A CNC milling machine comprises various critical components and intricate parts that integrate to facilitate precise cutting operations on material workpieces. This section explores the primary machine elements and the milling tools utilized. Major Machine Parts. Axes: CNC milling machines typically have multiple axes, with three-axis and five Hello! To kick-start the incorporation of CNC machines courses and programming, you will need necessary and adequately strong machines such as CNC milling machines, CNC lathes, and CNC routers. These machines will provide a solid foundation for your faculty of engineering’s teaching and learning content. Best regards! Reply A CNC milling machine is a marvel of engineering, combining various components to transform raw material into intricate shapes and designs. The machine control unit (MCU) is pivotal in managing the machine’s movements and operations, while the core components function in unison to enable efficient operation and accurate cnc machine work capabilities.

The principle parts of milling machine are given: Base The base of the machine is Grey iron casting accurately machined on its top and bottom surface and serves as a foundation member for all the other parts which rest upon it. . Milling Machine Parts and their Function. Author: ninjacraze. Dec 24, 2009. . I AM PARTCIPAT IN THE SEMANER CNC . The significance for CNC machine parts and their function shows that this machining method has taken over all forms of old manufacturing. . The CNC milling machine has a vast and composed structure, it performs many tasks simultaneously. CNC machines are the total opposite of older machining methods. Computer numerical control machines have .A horizontal milling machine functions similarly to a vertical mill with the exception that it uses a rotating table instead of a gantry and its main cutter is generally three- or four-pointed. . Parts of the Milling Machine. Main Parts of the Milling Machine: Column and Base. . The CNC milling machine and setup are more expensive than .

CNC milled parts have high tolerance as milling machines can achieve a tolerance between +/- 0.001 in. to +/- 0.005 in (some machines can achieve a tolerance of +/- 0.0005 in). CNC milling is widely used in industries such as aerospace, automotive, and electronics due to its ability to produce complex, high-quality components with minimal human .A typical vertical CNC milling machine has three axes, allowing the tooling to move vertically. Horizontal Milling: Like vertical milling machines, horizontal milling machines have a principal function, but in horizontal milling, the tooling spins horizontally. Both types of milling machines use similar types of tooling.

schematic diagram of cnc machine

pv junction box conecting

pv junction box manufacturers india

TE's power distribution boxes are flexible, cost-effective, and suitable for complex automotive and heavy-duty vehicle networks. Ask about our standalone modules and integrated solutions.

cnc milling machine parts and function|block diagram of cnc machine