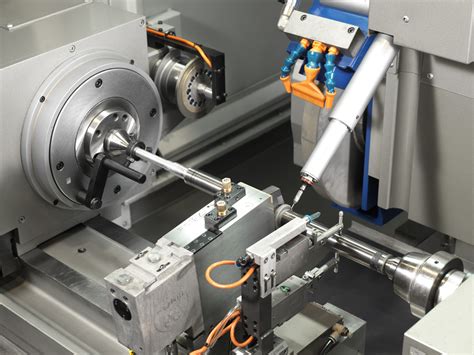

cnc machine grinding CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these . Make use of filler metals that are thinner compared to slimmer metal sheets. Many welders use 0.024-inch and 0.023 inches for thinner metal sheets. Metals such as stainless steel feature a wire diameter of 0.034 and 0.030 inches.A burnout takes place if the melted weld pool caves in and separates from the workpiece. The outcome is a big hole rather than an ideal joint. The fault takes place because of high-temperature outputs, which are unbearable to work with. If this happens, then the welder has to begin all over again with a fresh . See more

0 · micromatic cylindrical grinding machine

1 · external cylindrical grinding machine

2 · cylindrical grinding machine manufacturers

3 · cnc internal grinding machine

4 · cnc grinding machine specifications

5 · cnc grinding machine manufacturers

6 · cnc end mill grinding machine

7 · cnc cylindrical grinding machine price

An edge-to-edge joint is a type of welding joint where the two pieces of metal being joined are placed flush with each other, creating a weld-like surfacing weld. This type of joint is often used when joining sheet metal or thin plates.

CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming . CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these .Okuma has a full line of both ID and OD grinders, with both plain and angled heads, suitable for everything from high production to small job shops. Join us in the shop for useful approaches you can implement to tackle your daily workflow. We have machines in stock! Click here to see our current inventory. The UNITED GRINDING Group intends to acquire the GF .

CNC grinding is a highly advanced machining technique that offers high precision, accuracy, and efficiency. In the quest for the optimal grinding method, turning to CNC grinding . CNC, short for Computer Numerical Control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. This process allows for highly .

All Weldon CNC grinders are specifically configured, tooled and programmed to suit the end user’s most demanding requirements. Our capabilities include not only conventional grinding, but high speed superabrasive grinding, where we .CNC grinding involves removing small amounts of materials via a high-speed abrasive wheel as the cutting tool. This wheel rotates in place while the part or workpiece attached to the machine table moves in the X-, Y-, and Z-axis. Fritz Studer AG is a market and technology leader in universal, external and internal cylindrical grinding as well as noncircular grinding. A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.

CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming process and minimizes errors. CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these tools represent grinding machines designed to mold the workpiece in diverse manners.Okuma has a full line of both ID and OD grinders, with both plain and angled heads, suitable for everything from high production to small job shops. Join us in the shop for useful approaches you can implement to tackle your daily workflow. We have machines in stock! Click here to see our current inventory. The UNITED GRINDING Group intends to acquire the GF Machining Solutions Division (GFMS) of Georg Fischer AG (GF), Schaffhausen (Switzerland).

CNC grinding is a highly advanced machining technique that offers high precision, accuracy, and efficiency. In the quest for the optimal grinding method, turning to CNC grinding machines allows for a level of control that no manual counterpart can achieve.

micromatic cylindrical grinding machine

external cylindrical grinding machine

CNC, short for Computer Numerical Control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites.All Weldon CNC grinders are specifically configured, tooled and programmed to suit the end user’s most demanding requirements. Our capabilities include not only conventional grinding, but high speed superabrasive grinding, where we lead the industry in .

CNC grinding involves removing small amounts of materials via a high-speed abrasive wheel as the cutting tool. This wheel rotates in place while the part or workpiece attached to the machine table moves in the X-, Y-, and Z-axis.

Fritz Studer AG is a market and technology leader in universal, external and internal cylindrical grinding as well as noncircular grinding. A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency. CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming process and minimizes errors.

CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these tools represent grinding machines designed to mold the workpiece in diverse manners.Okuma has a full line of both ID and OD grinders, with both plain and angled heads, suitable for everything from high production to small job shops. Join us in the shop for useful approaches you can implement to tackle your daily workflow. We have machines in stock! Click here to see our current inventory. The UNITED GRINDING Group intends to acquire the GF Machining Solutions Division (GFMS) of Georg Fischer AG (GF), Schaffhausen (Switzerland).

CNC grinding is a highly advanced machining technique that offers high precision, accuracy, and efficiency. In the quest for the optimal grinding method, turning to CNC grinding machines allows for a level of control that no manual counterpart can achieve. CNC, short for Computer Numerical Control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites.All Weldon CNC grinders are specifically configured, tooled and programmed to suit the end user’s most demanding requirements. Our capabilities include not only conventional grinding, but high speed superabrasive grinding, where we lead the industry in .

CNC grinding involves removing small amounts of materials via a high-speed abrasive wheel as the cutting tool. This wheel rotates in place while the part or workpiece attached to the machine table moves in the X-, Y-, and Z-axis.

cylindrical grinding machine manufacturers

steel recessed av wall box

When it comes to welding thin sheet metal like car body panels, if you are not experienced and skilled enough, then you can easily create a mess as blow holes in the sheet and make the metal useless.

cnc machine grinding|cnc grinding machine manufacturers