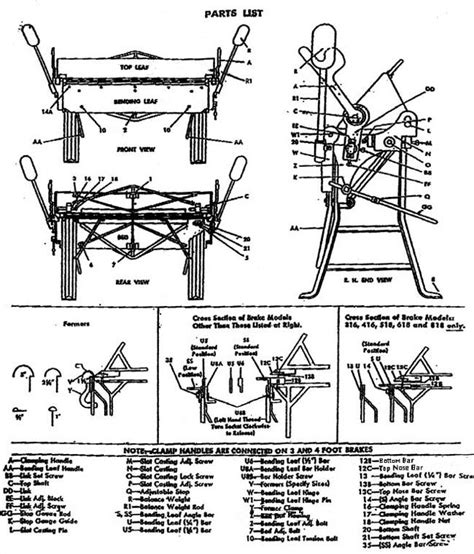

sheet metal brake diagram We begin by defining the press brake and its fundamental role in sheet metal fabrication. The guide then delves into a detailed examination of the key components of a hydraulic press brake, including the frame, ram, bed, . Make use of filler metals that are thinner compared to slimmer metal sheets. Many welders use 0.024-inch and 0.023 inches for thinner metal sheets. Metals such as stainless steel feature a wire diameter of 0.034 and 0.030 inches.

0 · sheet metal brake machine instructions

1 · homemade sheet metal press brake

2 · homemade sheet metal bending brake

3 · hobby sheet metal brake

4 · hand held sheet metal brake

5 · adjustable width sheet metal brakes

6 · adjustable sheet metal brakes

7 · 10 inch sheet metal brakes

How Do You Use MIG Welders to Weld Thin Metal? With the SCT (Short-Circuit Transfer) model for slim-gauge metals, you can produce perfect weld seams, even for thin metals. The SCT also lessens the contortion of welds above the joint. Additionally, it reduces the appearance of burnouts (melted metal puddles). It involves the conveyance of low heat.

Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. .

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box .

The Sheet Metal Brake I always wanted: 36" glory, cantilever locking mechanism, adjustable fingers, weighs as much as I do! (NOTE: . LINK TO FREE PLANS BELOW!

We’ve poked at bending sheetmetal in a previous installment of Wrenchin’ Wednesday, but today we’re going to talk about how to build your own sheetmetal brake for .

We begin by defining the press brake and its fundamental role in sheet metal fabrication. The guide then delves into a detailed examination of the key components of a hydraulic press brake, including the frame, ram, bed, .

Here we explain how to use and adjust a sheet metal brake. We also explain how to make a sheet metal box or pan. It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag.With your DIY metal brake complete, it's time to test it out. Start by clamping down a sheet of 18-gauge (1 mm thick) steel and bending it to 90 degrees. If everything is aligned properly, you .DIY Sheet Metal Bender Brake Fully Modified: At a previous instructable, we had seen the build of a simple version, Sheet Metal Brake. The brake works pretty good but, has some limitations. The thickness of bending material can't be .In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian . Brake press Finger brake . Material drawn into shape •Conventional drawing/stamping – expensive tooling, no net thinning, quick . Tensile test – the Stress-strain diagramTapco Tools Sheet Metal Brakes. A tool for every job. From small outfits to commercial projects to everything in between, Tapco Tools offers a brake to help you achieve the perfect high-quality finish. Tapco brakes are versatile, easy to .This sheet metal brake can be easily built in a home workshop for next to nothing, and will bend aluminum sheets 1/8" thick and 24" wide, and up to 135°, though it can bend thinner aluminum and steel sheets up to 36" wide. The build article .

magnabend hinge Magnetic sheet metal brake HingeSheet metal brake parts play a crucial role in the metalworking industry. These parts are used in various machines, including press brakes, and are essential for bending and shaping sheet metal with precision. The main components of sheet metal brake parts include: 1. Bed or Beam: This is the horizontal surface of the brake where the material .ALWAYS check the Zone Working Area (see Safe Zone Diagram pg. 3) before you start your bend. Be sure the area is clear of ALL people. Use Common sense when using this brake. . BRAKES WARRANTY National Sheet Metal Machines, Inc. warrants this product to be free of defects in material and / or workmanship for a period of THREE (3) YEARS from .Brake Buddy™ Instant roll forming tool. Side-Winder™ Works in tandem with all PRO Series Brakes. PRO™ Cut-Off Quickly, safely, and easily makes factory quality cuts in coil stock, sheet metal, and vinyl siding right on your Brake. Snap Stand™ Heavy Duty Transportable Support; sets up in seconds. Wheel Kit Allows for easy transport of .

This sheet metal shear is designed with sheet support up to 14-gauge support and has stainless steel rectangular gauges with a scale of 400 mm (15.75 inches). Schechtl MSC Shear This sheet metal shear is designed with sheet support for up to 11-gauge support and is the heaviest cutting shear for Schechtl.

can you die from touching an electric box

Metalworking » Sheet Metal Brakes » Bench Sheet Metal Brakes; Previous Slide Next Slide *Image may display optional items not included with purchase. You might also be interested in. National Bench Brake S4816. ,175.00. Baileigh Sheet Metal Brake HB-4816E. ,039.00. Baileigh Sheet Metal Brake BB-4816E.

show diagrams. catagory 2 search × clear filters . 67 68 69 camaro sheet metal. 1967 camaro firebird door parts. . 1968-79 nova 67-69 camaro firebird parking brake parts. 67 68 camaro firebird ac under dash duct. 1964-68 chevy small block ac compressor brackets. Just take out some time from your busy schedule and start making these homemade sheet metal brakes at home today! You Can See: 25 DIY Welding Table Plans You Can Make Easily. Make A Sheet Metal Brake. Making your own sheet metal brake is quick and easy. All you need to make this DIY sheet metal brake is an angle iron, a square tube, a flat .

sheet metal brake machine instructions

Sheet Metal Brake: This is a simple sheet metal brake that I designed. It's relatively inexpensive at a total cost of , it's easy to build, and it works really well. After looking at the other designs on instructables and youtube, they seemed to be either too com. Sheet Metal Straight Brake . 16Ga Models #2800-4816S / #2800-7216S / #2800-9616S . 22Ga Models #2800-7222S / #2800-9622S . CAUTION: Read and Understand . The brake may be used to form hems on the edge of the work-piece in lighter materials. A hem is formed by making an acute (reverse) bend in the work-piece (apron and then clamping the . Sheet metal bending is a deformation process that uses a machine called a brake to bend metal. Metal can be bent into U shapes, V shapes, or channel to an angle of up to 120 degrees. 331-223-4378 [email protected]

Manual press brakes, also known as sheet metal brakes, are the most basic and traditional type of press brakes. They require manual adjustment of bending dimensions and angles during operation. The key components of a .You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake teeth right on your lines. If your line is clamped down at an angle to your brake teeth, you will bend your metal at an angle and your box .Prepare locations for machine. (See Safe Zone Diagram pg. 2, Anchor Points pg. 15, and Machine Dimensions Chart pg. 13 for proper positioning) 2. Install Anchors into floor at desired location. . BRAKES WARRANTY National Sheet Metal Machines, Inc. warrants this product to be free of defects in material and / or workmanship for a period of .show diagrams. catagory 2 search × clear filters . 67 68 69 camaro sheet metal. 68 69 camaro firebird door parts. . 1968-79 nova 67-69 camaro firebird parking brake parts. 67 68 camaro dash parts. 67 68 69 camaro firebird convertible top frame & parts.

The Woodward Fab Model WFBOSS16 Sheet Metal Brake is designed to bend sheet metal stock in widths up to 48” and a maximum thickness of 16 gauge (.062”) The machines come with removable bending dies (fingers) to allow box forming and customization in 1” increments. The Boss Brake also has an adjustable counterweight assembly and depth stop.Several years back, I put together a larger sheet metal brake that didn't involve welding. I decided to loosely copy this design and scale everything down. Supplies. I used the following materials: A section of 3/4" steel angle iron. A section of 1/2" steel angle iron. Two 2" wide hinges. 10-32 Screws (x15) Spray paint. Buy KAKA INDUSTRIAL EB-5216 Magnetic Sheet Metal Brake, 52-Inch 16-Gauge 6.5-ton Magnetic Power Magnetic Clamping Pan and Box Bending Brake,Bend Boxes or Pans to Any Depth 220V-60HZ-1PH: Press Brakes - Amazon.com FREE DELIVERY possible on .

Baileigh Industrial is an international provider of quality metal machinery. Our proven industry leadership results in profitable solutions for your fabricating needs. Manuals - Baileigh IndustrialThe brake’s compact size can accommodate sheet metal stock up to 4-feet wide, in any length, because there is no fixed throat depth to contend with. Use the Mini Brake anywhere on the job site, even on a truck tailgate, for a variety of fabricating tasks from large HVAC transitions to narrow roof flashing to structures as small as a 4-inch .Sheet metal brakes are tools used for bending and shaping sheet metal into desired forms. The primary function of a sheet metal brake is to create precise bends along straight lines in the metal. These machines are particularly valuable in various industries, including automotive, construction, and appliance manufacturing.

Bending sheet metal with a brake is a skill that combines the right equipment, proper techniques, and an understanding of the material you are working with. From choosing the appropriate brake and its accessories to mastering both basic and advanced bending techniques, each step is crucial in achieving precise and high-quality results.Cody goes over how to use the electro brake and fabricate a simple box using a few different attachments! More Info: https://www.eastwood.com/48-inch-electro.Ironton Portable Sheet Metal Bending Brake, 30in. Wide. Item # 101452. .99 . Shipping: Available now See Shipping Options. Store Pickup: Check Store Stock. Add to Cart. Activating this checkbox will add this item to the product comparison tool. Compare Save to List. Shop Fox 3-in-1 Combination Sheet Metal Machine, 12in., Model# M1052.

homemade sheet metal press brake

homemade sheet metal bending brake

Get more information for Wells Fargo in Princeton Junction, NJ. See reviews, map, get the address, and find directions.

sheet metal brake diagram|10 inch sheet metal brakes