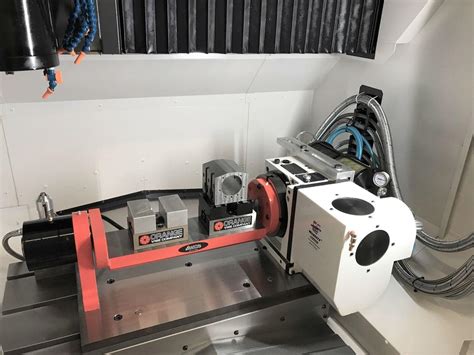

4th axis reduction in cnc machines Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.

MR Truss industrial universal truss junction box offers more flexibility over traditional truss corners, allowing for 6-way connections and fits all Major Name Brands 11.4\" Truss. General Features: To Fit: Standard F34 Square Truss Configurations.

0 · cnc 4th axis for sale

1 · 4th axis rotary cnc

2 · 4th axis for cnc mill

3 · 4 axis hobby cnc

4 · 4 axis desktop cnc mill

5 · 4 axis desktop cnc

6 · 4 axis cnc mill cost

7 · 4 axis cnc for sale

The TRUMPF storage and logistics systems provide you with a modular system of .

To set up the axis within Mach it is necessary to specify the ‘Steps Per’ (degree) and this is achieved by taking the steps of the stepper motor and multiplying by the micro stepping setting (if any) and then multiplying by the gear ratio then dividing the result by 360. Rarely is a 4th axis used as a lathe and if so a mechanical brake is typically put in place. I’ve seen low ratios work fine and there is even a company running a 1:1 now with a . I purchased two used Harmonic Drive Planetary reduction units, 22:1 for the "A" axis, 5:1 plus the original 8:1 belt for the "B" axis. Custom machined many parts and now they . It’s a 150mm DIY 4th axis (based on a harmonic drive reduction) with an electromagnetic disk brake. The basis of the project is a 100:1 reduction harmonic drive .

I would like to present the latest addition to my workshop. It’s a 150mm DIY 4th axis (based on a harmonic drive reduction) with an electromagnetic disk brake. The basis of the .Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.

3-axis CNC Milling Machines include axes that can move along the X-axis, Y-axis, and Z-axis dimensions–pretty basic stuff. A 4-axis CNC machine adds a rotating A-axis, enhancing the typical three-axis setup. This allows for more complex . 4-Axis CNC machining involves multi-axis machining of workpiece material with CNC machines with an extra rotary axis. The 4-axis machining process utilizes any CNC machine that can simultaneously move at four .

cnc 4th axis for sale

4-axis CNC machining works by adding a rotary axis, known as the A-axis, to the traditional X, Y, and Z axis. The A-axis allows the machine to rotate the part being worked on, which adds greater precision and flexibility to the . To set up the axis within Mach it is necessary to specify the ‘Steps Per’ (degree) and this is achieved by taking the steps of the stepper motor and multiplying by the micro stepping setting (if any) and then multiplying by the gear ratio then dividing the result by 360. Rarely is a 4th axis used as a lathe and if so a mechanical brake is typically put in place. I’ve seen low ratios work fine and there is even a company running a 1:1 now with a harmonic drive and servo which has amazing resolution, low torque, and high speeds.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

I purchased two used Harmonic Drive Planetary reduction units, 22:1 for the "A" axis, 5:1 plus the original 8:1 belt for the "B" axis. Custom machined many parts and now they are backlash free, can hold 25 lbs. static and stronger than the rest of the mill. It’s a 150mm DIY 4th axis (based on a harmonic drive reduction) with an electromagnetic disk brake. The basis of the project is a 100:1 reduction harmonic drive imported from Japan. For compactness, I went for one of their CSD units (CSD-25-100-2A-GR-SP) which has an overall length of just 17mm and an OD of 85mm. I would like to present the latest addition to my workshop. It’s a 150mm DIY 4th axis (based on a harmonic drive reduction) with an electromagnetic disk brake. The basis of the project is a 100:1 reduction harmonic drive imported from Japan.Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.

3-axis CNC Milling Machines include axes that can move along the X-axis, Y-axis, and Z-axis dimensions–pretty basic stuff. A 4-axis CNC machine adds a rotating A-axis, enhancing the typical three-axis setup. This allows for more complex part geometries and . 4-Axis CNC machining involves multi-axis machining of workpiece material with CNC machines with an extra rotary axis. The 4-axis machining process utilizes any CNC machine that can simultaneously move at four different angles. 4-axis CNC machining works by adding a rotary axis, known as the A-axis, to the traditional X, Y, and Z axis. The A-axis allows the machine to rotate the part being worked on, which adds greater precision and flexibility to the manufacturing process.

To set up the axis within Mach it is necessary to specify the ‘Steps Per’ (degree) and this is achieved by taking the steps of the stepper motor and multiplying by the micro stepping setting (if any) and then multiplying by the gear ratio then dividing the result by 360. Rarely is a 4th axis used as a lathe and if so a mechanical brake is typically put in place. I’ve seen low ratios work fine and there is even a company running a 1:1 now with a harmonic drive and servo which has amazing resolution, low torque, and high speeds. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

I purchased two used Harmonic Drive Planetary reduction units, 22:1 for the "A" axis, 5:1 plus the original 8:1 belt for the "B" axis. Custom machined many parts and now they are backlash free, can hold 25 lbs. static and stronger than the rest of the mill.

It’s a 150mm DIY 4th axis (based on a harmonic drive reduction) with an electromagnetic disk brake. The basis of the project is a 100:1 reduction harmonic drive imported from Japan. For compactness, I went for one of their CSD units (CSD-25-100-2A-GR-SP) which has an overall length of just 17mm and an OD of 85mm.

I would like to present the latest addition to my workshop. It’s a 150mm DIY 4th axis (based on a harmonic drive reduction) with an electromagnetic disk brake. The basis of the project is a 100:1 reduction harmonic drive imported from Japan.Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.3-axis CNC Milling Machines include axes that can move along the X-axis, Y-axis, and Z-axis dimensions–pretty basic stuff. A 4-axis CNC machine adds a rotating A-axis, enhancing the typical three-axis setup. This allows for more complex part geometries and .

4-Axis CNC machining involves multi-axis machining of workpiece material with CNC machines with an extra rotary axis. The 4-axis machining process utilizes any CNC machine that can simultaneously move at four different angles.

4th axis rotary cnc

18 cu.in. electrical box square

4th axis for cnc mill

TULIP Metallic Gold and Silver Dimensional Fabric Paint, 4 Fl Oz - 17372 Gold and 17371 Silver

4th axis reduction in cnc machines|4th axis rotary cnc