12 axis cnc machine 12-axis CNC. The 12-axis CNC machine is at the top of the performance and capability list for CNC machine. The design of the machine features 2 heads that facilitate . $17.99

0 · multi axis cnc machines

1 · mill xyz axis

2 · cnc machine axis identification

3 · cnc axis explained

4 · axis identification in cnc machine

5 · 2 axis cnc milling machine

6 · 12 axis cnc mill

7 · 12 axis cnc machine price

A 4×8 plywood CNC machine is the best tool for this since it minimizes material waste, and cuts the parts fast and accurately out of the sheet. You can build tables, chairs, nightstands, TV stands, dog houses, and more.

Capabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have .12-axis CNC machines are advanced pieces of equipment that stands at the pinnacle of performance and capability in CNC technology. 12-axis machines typically contain two heads, each capable of moving along six different axes: . 12-axis CNC. The 12-axis CNC machine is at the top of the performance and capability list for CNC machine. The design of the machine features 2 heads that facilitate . 12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two .

Use the up and down arrows to select a result. Press enter to go to the selected search result. Touch device users can use touch and swipe gestures. All large-frame models come with an upgraded features package that includes a side . The most complex device in the manufacturing industry is a 12-axis CNC machine. It has two cutting heads that can move along all six axes (X, Y, Z, A, B, C). 12-axis CNC machine improves precision and production rates. 12-axis Machining Finally, you can use 12-axis machining which requires special rotary motion around a length and width plus a travel axis moving along both. As a result, you .To grasp the significance of a 12-axis CNC machine, it is essential to understand the fundamentals of CNC machining. We will explore how a CNC machine works, breaking down .

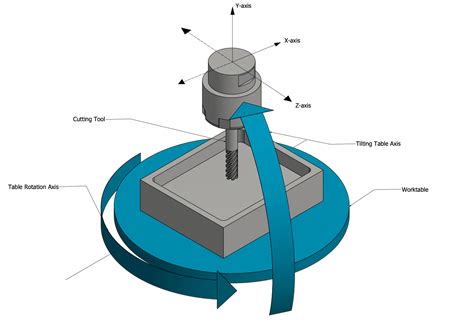

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.Capabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have advanced the technology to the point where there are no more degrees of freedom proposed or discussed.12-axis CNC machines are advanced pieces of equipment that stands at the pinnacle of performance and capability in CNC technology. 12-axis machines typically contain two heads, each capable of moving along six different axes: X, Y, Z, A, B, and C.

12-axis CNC. The 12-axis CNC machine is at the top of the performance and capability list for CNC machine. The design of the machine features 2 heads that facilitate movement along axes X, Y, Z, A, B and C planes. 12-axis CNC machines are designed for the most demanding operations that have an array of complexities in their design. 12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two heads that allow movement along the X, Y, Z, A, B, and C-axes. This configuration doubles productivity and accuracy while cutting down manufacturing time by half!Use the up and down arrows to select a result. Press enter to go to the selected search result. Touch device users can use touch and swipe gestures. All large-frame models come with an upgraded features package that includes a side-mount tool changer, chip auger, programmable coolant nozzle, and remote jog handle. 美元价格不包括关税、报关费用、保险费、增值税及运 .

The most complex device in the manufacturing industry is a 12-axis CNC machine. It has two cutting heads that can move along all six axes (X, Y, Z, A, B, C). 12-axis CNC machine improves precision and production rates. 12-axis Machining Finally, you can use 12-axis machining which requires special rotary motion around a length and width plus a travel axis moving along both. As a result, you can use it in the most advanced compounds with specialized applications requiring high precision.To grasp the significance of a 12-axis CNC machine, it is essential to understand the fundamentals of CNC machining. We will explore how a CNC machine works, breaking down its components and functions, before diving into the specifics of the 12-axis variant. An examination of the functions and capabilities of various multi-axis CNC milling machines, from 3-axis to 5-axis to 12-axis machining!

multi axis cnc machines

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.Capabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have advanced the technology to the point where there are no more degrees of freedom proposed or discussed.12-axis CNC machines are advanced pieces of equipment that stands at the pinnacle of performance and capability in CNC technology. 12-axis machines typically contain two heads, each capable of moving along six different axes: X, Y, Z, A, B, and C. 12-axis CNC. The 12-axis CNC machine is at the top of the performance and capability list for CNC machine. The design of the machine features 2 heads that facilitate movement along axes X, Y, Z, A, B and C planes. 12-axis CNC machines are designed for the most demanding operations that have an array of complexities in their design.

12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two heads that allow movement along the X, Y, Z, A, B, and C-axes. This configuration doubles productivity and accuracy while cutting down manufacturing time by half!

Use the up and down arrows to select a result. Press enter to go to the selected search result. Touch device users can use touch and swipe gestures. All large-frame models come with an upgraded features package that includes a side-mount tool changer, chip auger, programmable coolant nozzle, and remote jog handle. 美元价格不包括关税、报关费用、保险费、增值税及运 .

The most complex device in the manufacturing industry is a 12-axis CNC machine. It has two cutting heads that can move along all six axes (X, Y, Z, A, B, C). 12-axis CNC machine improves precision and production rates. 12-axis Machining Finally, you can use 12-axis machining which requires special rotary motion around a length and width plus a travel axis moving along both. As a result, you can use it in the most advanced compounds with specialized applications requiring high precision.

To grasp the significance of a 12-axis CNC machine, it is essential to understand the fundamentals of CNC machining. We will explore how a CNC machine works, breaking down its components and functions, before diving into the specifics of the 12-axis variant.

cnc machine programs

mill xyz axis

Red Co. Rustic Galvanized Metal Storage Box with Wooden Lid 12"W x 6.5"D - Country Style

12 axis cnc machine|cnc axis explained