types of sheet metal joints and their uses Learn more about the five basic types of weld joints recognized by the American Welding Society, and get tips for welding each type to help achieve the best results. Butt joint; Corner joint; Edge joint; Lap joint; T-joint; . Wood drawer box holds bins and provides a clean neutral look; Heavy-duty, under-mount slide with soft-close technology; Unique, washable, solid floor; Prevents debris from falling through to floor/cabinet; Easy to clean; .

0 · types of sheet metal seams

1 · sheet metal overlap joint

2 · sheet metal joints pdf

3 · sheet metal joints and seams

4 · sheet metal clinching joint

5 · interlocking sheet metal joints

6 · different types of metal joints

7 · different joining methods for metal

The real trick to pulling in PVC is not to use factory 90's, use the hot box and make longer sweeps. If you catch someone using factory 90's at floor boxes, hit them with something. LarryFine

Learn more about the five basic types of weld joints recognized by the American Welding Society, and get tips for welding each type to help achieve the best results. Butt joint; Corner joint; Edge joint; Lap joint; T-joint; . Following are the 5 main types of welding joints: Butt joint welding. Lap joint welding. Edge joint welding. Discover the 7 most common sheet metal joint techniques that include riveted, welded, and adhesive joint types for appropriate enhancement of structural rigidity and effectiveness in your projects. A butt joint is one of the most common and straightforward types of welding joints. It involves two metal plates placed edge to edge in the same plane and welded along the .

These types of joints are among the most common in the sheet metal industry, found in the construction of frames, boxes, and other applications. There are two ways of fitting up an outside corner joint—either forming a V .

Welding joints is the procedure of connecting a couple of pieces of metal (or plastic) at an edge or a point. Numerous factors come into play here including the shape of the materials, and certain geometrical aspects. These types of joints are among the most common in the sheet metal industry, found in the construction of frames, boxes, and other applications. There are two ways of fitting up an outside corner joint—either forming a V . Although sheet metal has its applications and knows for its unique qualities, there is no particular definition better than that. It’s instead called a processing technology that is the handbook or metal workers. What is Sheet .

What are the Five Types of Welding Joints? The five kinds of weld joints are butt, corner, lap, tee, and edge joints. 1. Butt Joint. A butt joint is a common type of joint used in the fabrication of structures and piping systems, where two pieces of metal are placed together in the same plane, and the side of each metal is joined by welding.

This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications. Factors affecting the selection of type of Sheet Metal Joint. . Adhesive bonding is a type of permanent joint used in sheet metal parts. You can disassemble parts using chemicals. For adhesive bonding, you need to place the . You might like: Different Types of Welding Rods and Their Uses #2 Lap Joint Welding. . These joints are some of the common types in the industries of sheet metals, such as in the manufacture of boxes, frames, and other applications. The drawbacks like lamellar tearing, incomplete penetration, porosity, slag inclusion, etc will occur in the . Similar to tee welding joints, they are corner joints. However, the placement of the metal makes a difference. In contrast to corner joints, which can meet in the 'corner' in either an open or closed way to form an 'L' shape, tee joints place their joint in the middle. These joints are among the most used in the sheet metal industry. These joints are popular in the sheet metal industry, where they’re used to make frames, boxes, and other items. An outside corner junction can be fitted in two ways: either a V-groove or a square butt joint. The styles used for creating corner joints include: Spot, edge, and fillet weld; V, J, and U-groove weld; Bevel-groove weld; Corner .

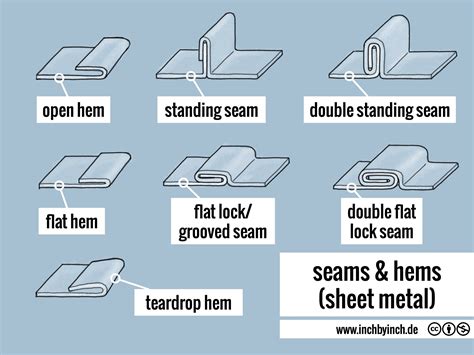

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. Hemming Straight Hem.(Image source) (Image source) Contour hemming.(Image source) Hem detail.(Image source) Types of Hemming.(Image . Chart Types and Their Uses. Chart Types and Their Uses. AREA CHARTS. Use it to.. Display over time (or any other dimension) How a set of data adds up to a whole (cumulated totals) Which part of the whole each element represents . Column/Bar Chart. Use it to.. Present few data; useful for comparisons of data . 878 views • 27 slides Certain joint types may require more time or resources to complete, while others may introduce additional challenges in terms of positioning or accessibility. As such, understanding the various sheet metal welding joint types and their applications is vital for both novice and experienced welders alike. Chapter #6 – Sheet Metal Seams. Seams run longitudinal along the length of the duct run, while joints run transverse (across). Seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.

Different Types of Welding Joints and their Uses. An intricate and tortuous craft, welding demands in-depth knowledge of the methods of welding, evolving techniques and different types of welding joints. Weld joints implies joining two or more metal or non-metal parts together to form a single unit, by using a specific technique and geometry.

types of sheet metal seams

sheet metal overlap joint

The edge joint provides a clean and seamless connection between the two pieces of metal. It is commonly used in sheet metal fabrication, automotive manufacturing, and the construction of thin-walled structures. This type of joint is particularly useful when aesthetics and smoothness are important.

The Bell type joint is also approved for use by the IMC (International Mechanical Code). . The fabrication shop has to determine what their standard fabrication preference is and the cost for the various options based on stiffener spacing. . Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air .

Here’s how to use sheet metal screws: Choose the Right Sheet Metal Screws: Select sheet metal screws based on the material, thickness of the sheet metal, and the required fastening force. . Types of Welding Joints: The .

What are Welding Joints? The welding joints are edges otherwise points where different metal or plastic pieces are connected together. These can be formed by connecting various metals otherwise plastic pieces based on an exact .

Different Types of Fasteners and Their Applications. . However, the machinist should ensure accurate threading to suit the securing of the joints. 1.2 Sheet Metal Screws. These screws possess sharp cutting edges that promote easy cutting and penetration through sheet metals. Sheet metal screws have fully threaded shank to enable good chip . These joints are popular in the sheet metal industry, where they’re used to make frames, boxes, and other items. An outside corner junction can be fitted in two ways: either a V-groove or a square butt joint. The styles used for creating corner joints include: Spot, edge, and fillet weld; V, J, and U-groove weld; Bevel-groove weld; Corner . This type of joint is commonly used when welding thin materials, such as sheet metal, where other joint configurations may not provide sufficient strength or stability. Applications: Lap joints are widely used in: Sheet Metal Work: This joint is ideal for joining thin sheets of metal, commonly found in the automotive and aerospace industries. The edge joint provides a clean and seamless connection between the two pieces of metal. It is commonly used in sheet metal fabrication, automotive manufacturing, and the construction of thin-walled structures. This type of joint is particularly useful when aesthetics and smoothness are important.

Some commonly used fastener types include machine screws, wood screws, self-tapping screws, and sheet metal screws. These fasteners may have hexagonal or rounded heads, as well as smooth shanks. In addition to these standard types, there are also a multitude of specialty fasteners such as permanent fasteners, single-use fasteners, high-quality . Riveting is a joining technique that uses a rivet (a type of fastener) to join two parts. It is popular in industries like automotive, aircraft, building, construction, etc. . 0.030-inch metal sheets stack up. The thickest sheet is 0.040 inches 3(0.040) = 0.120. 1/32 = 0.03125 . body or rivet pin and a mandrel which falls off during .

Lap joints are ideal in applications like sheet metal work and fabrication. They provide excellent strength and resistance to shear forces, making them reliable for various structural purposes. Welding Techniques and Their Influence on Joint Types. Welding techniques significantly influence the types of joints formed in metal fabrication.Introduction. Types of Pipe Joints and Their Uses in Plumbing [Complete Guide]: – Pipe couplings in the water supply are important components of the plumbing system that allow several pipes to be connected. Pipe joints come in various shapes and sizes, and their selection is based on factors such as pipe size, material, and flow pressure. A nut, anchor bolt, screw, clips, etc, all are a different kind of fasteners. There are metal fasteners that can be used to join materials such as wood, sheet metal, plastics, etc. together. Made from different kinds of metals such as steel, aluminum, brass they come in various shapes and sizes to suit the needs of different projects.

This joint is commonly used for joining two pieces of metal with similar thickness. Butt joints are commonly used in industries such as automotive, construction, and shipbuilding. 2. Lap Joint: In a lap joint, one metal piece overlaps the other, and the two pieces are welded together. Lap joints are versatile and are often used in applications . An edge joint is a type of joint where two metal pieces are placed such that the edges of both are even. One or both plates may be formed by bending them at an angle. In this weld joint, the metal pieces are placed together such that the stresses are distributed. It is used in joining sheet metal parts, especially corner making.

sheet metal joints pdf

sheet metal joints and seams

$11.99

types of sheet metal joints and their uses|sheet metal clinching joint