bending operation sheet metal process This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Custom Aluminum Parts. eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. No Minimum Order Quantity. 100% Quality Guaranteed.

0 · sheet metal working process pdf

1 · sheet metal bending pdf

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending dies

5 · minimum bend radius sheet metal

6 · maximum thickness sheet metal bending

7 · identify a characteristic of bending

Axis CNC Plasma Cutting Machines utilize precision linear rails to achieve a superior level of accuracy, smooth fluid motion and high duty cycle. We offer a full line of Hypertherm Mechanized Plasma Cutting Power Supplies, CNC .

sheet metal working process pdf

What is Sheet Metal Bending Operation? The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation of the workpiece. The type of bend and bend .Clearance between punch and die is required to facilitate the fracture of sheet .Sheet metal bending is a forming operation where sheets are deformed plastically to .At its core, sheet metal bending involves applying force to a metal sheet, causing it to bend at an angle and form a desired shape. This process requires specific sheet metal bending machines or press brakes, which exert pressure on the .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.Most sheet metal bending operations involve a punch die type setup, although not always. There are many different punch die geometries, setups and fixtures. Tooling can be specific to a bending process and a desired angle of bend.

metal shelves boxes of paper

Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common .Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the . Sheet metal bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. Bending operation is permanent defamation about the new tool .What is Sheet Metal Bending Operation? The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation of the workpiece. The type of bend and bend length depends on punch and die design.

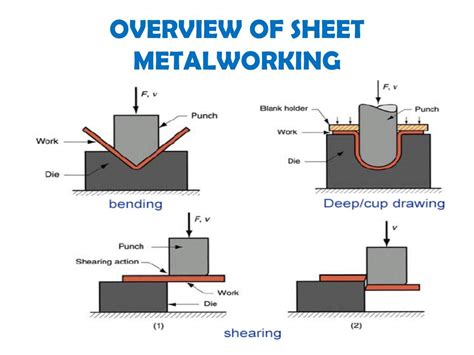

Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.At its core, sheet metal bending involves applying force to a metal sheet, causing it to bend at an angle and form a desired shape. This process requires specific sheet metal bending machines or press brakes, which exert pressure on the metal, ensuring accuracy and consistency.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.Most sheet metal bending operations involve a punch die type setup, although not always. There are many different punch die geometries, setups and fixtures. Tooling can be specific to a bending process and a desired angle of bend.

Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace.

Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending .

Sheet metal bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. Bending operation is permanent defamation about the new tool axis. Bending a sheet metal around a straight axis, take a permanent bend.What is Sheet Metal Bending Operation? The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation of the workpiece. The type of bend and bend length depends on punch and die design. Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

sheet metal bending pdf

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

At its core, sheet metal bending involves applying force to a metal sheet, causing it to bend at an angle and form a desired shape. This process requires specific sheet metal bending machines or press brakes, which exert pressure on the metal, ensuring accuracy and consistency.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.Most sheet metal bending operations involve a punch die type setup, although not always. There are many different punch die geometries, setups and fixtures. Tooling can be specific to a bending process and a desired angle of bend. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace.

Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending .

sheet metal bending near me

sheet metal bending guidelines

Keats provides custom metal stampings, assemblies, and wire forms to customers in the automotive, communications, construction, medical, electrical, appliance, and military industries, as well as makes discrete manufacturing products for aerospace, smartphones, and toys.

bending operation sheet metal process|identify a characteristic of bending