cnc drilling part programming A complete cnc part-program which shows how G98 and G99 (canned cycle return . Complete form 5329 to report the excess contributions. Box 3: Distribution Code: Not Supported in program. Use this code for normal distributions to the account holder and any direct payments to a medical service provider. Use this code if no other code applies. Use this code for payments to a decedent's estate in the year of death.

0 · peck drilling cycle programming

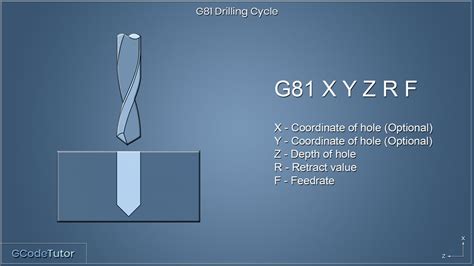

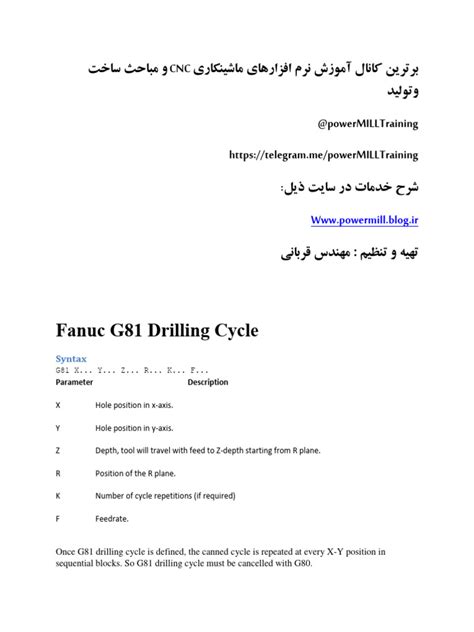

1 · g81 drilling cycle programming

2 · g81 drilling cycle pdf

3 · g code drilling cycle

4 · cnc programming exmaple code

5 · cnc g81 programming examples

6 · cnc g81 drilling cycle

Black sheet, also referred to as iron plate, is an untreated sheet metal that is extremely prone to rusting, at different rates depending on the composition of the external environment. To avoid corrosion, the sheet plate is surface treated (powder coated, for example), usually using an epoxy-polyester mixture.

Here is a cnc programming example for simple drilling on a cnc lathe machine. CNC Fanuc control has a very powerful and versatile peck drilling cycle (Fanuc G74) which relieves.This CNC program example shows how both G72.1 and G72.2 figure copy .

A complete cnc part-program which shows how G98 and G99 (canned cycle return .

fabric covered metal shelves

A good example of an operation that can be written directly with G-Code is the drilling cycle, so let’s dive in and look at how we can use the G81 drilling cycle on a CNC mill. Using G81 G81 is the standard drilling cycle that .A complete cnc part-program which shows how G98 and G99 (canned cycle return level) work with G81 drilling cycle and G83 peck drilling cycle for drilling . In this lesson, we take a look at the G81 drilling cycle and how to program it using G-Code on a CNC mill.This is part of a complete professional G-Code prog.This CNC program example shows how both G72.1 and G72.2 figure copy functions can call one-another in one part program, read Programming Notes below carefully. Programming Fanuc .

This video lecture describes a procedure to write a manual part program for drilling operation. The cnc program is written in G & M codes and describes a poi.

peck drilling cycle programming

Here is the CNC code. The machine first moves to X-55. Y-55. and rapids the Z axis to 3mm above the part. It then rapids the Z axis down to 1mm above the part R1. The G81 Cycle instructs it to drill a hole 6mm deep (Z .Here is a cnc programming example for simple drilling on a cnc lathe machine. CNC Fanuc control has a very powerful and versatile peck drilling cycle (Fanuc G74) which relieves.

A good example of an operation that can be written directly with G-Code is the drilling cycle, so let’s dive in and look at how we can use the G81 drilling cycle on a CNC mill. Using G81 G81 is the standard drilling cycle that produces our holes with just a few lines of code.A complete cnc part-program which shows how G98 and G99 (canned cycle return level) work with G81 drilling cycle and G83 peck drilling cycle for drilling of a component which have different heights. G98 and G99 are modal commands that change .

Ready to master CNC programming? Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today! When to use a G81 code? The G81 command is useful when you want to drill holes that are not too deep and can be drilled in just one step.

In this lesson, we take a look at the G81 drilling cycle and how to program it using G-Code on a CNC mill.This is part of a complete professional G-Code prog.This CNC program example shows how both G72.1 and G72.2 figure copy functions can call one-another in one part program, read Programming Notes below carefully. Programming Fanuc G72.1 Rotational Copy Using G72.1.

This video lecture describes a procedure to write a manual part program for drilling operation. The cnc program is written in G & M codes and describes a poi.

Here is the CNC code. The machine first moves to X-55. Y-55. and rapids the Z axis to 3mm above the part. It then rapids the Z axis down to 1mm above the part R1. The G81 Cycle instructs it to drill a hole 6mm deep (Z-6.) at a feed of 200mm per minute (F200.) When the hole is done it rapids back to the initial point (Z3.) This was in the line. CNC drilling, using Computer Numerical Control technology, offers precise and efficient hole-making capabilities. The machines can be programmed to drill holes in various shapes and sizes, making them versatile tools in manufacturing. The process involves a rotating drill bit guided by the CNC machine to create holes in desired locations.The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparation

Here is a cnc programming example for simple drilling on a cnc lathe machine. CNC Fanuc control has a very powerful and versatile peck drilling cycle (Fanuc G74) which relieves. A good example of an operation that can be written directly with G-Code is the drilling cycle, so let’s dive in and look at how we can use the G81 drilling cycle on a CNC mill. Using G81 G81 is the standard drilling cycle that produces our holes with just a few lines of code.

fabric metallic pen

A complete cnc part-program which shows how G98 and G99 (canned cycle return level) work with G81 drilling cycle and G83 peck drilling cycle for drilling of a component which have different heights. G98 and G99 are modal commands that change . Ready to master CNC programming? Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today! When to use a G81 code? The G81 command is useful when you want to drill holes that are not too deep and can be drilled in just one step.In this lesson, we take a look at the G81 drilling cycle and how to program it using G-Code on a CNC mill.This is part of a complete professional G-Code prog.This CNC program example shows how both G72.1 and G72.2 figure copy functions can call one-another in one part program, read Programming Notes below carefully. Programming Fanuc G72.1 Rotational Copy Using G72.1.

This video lecture describes a procedure to write a manual part program for drilling operation. The cnc program is written in G & M codes and describes a poi. Here is the CNC code. The machine first moves to X-55. Y-55. and rapids the Z axis to 3mm above the part. It then rapids the Z axis down to 1mm above the part R1. The G81 Cycle instructs it to drill a hole 6mm deep (Z-6.) at a feed of 200mm per minute (F200.) When the hole is done it rapids back to the initial point (Z3.) This was in the line.

g81 drilling cycle programming

g81 drilling cycle pdf

CNC drilling, using Computer Numerical Control technology, offers precise and efficient hole-making capabilities. The machines can be programmed to drill holes in various shapes and sizes, making them versatile tools in manufacturing. The process involves a rotating drill bit guided by the CNC machine to create holes in desired locations.

fabric hurricane shutters vs metal

g code drilling cycle

A non dividend distribution will be shown in Box 3 on this form. It is worth noting that Box 3 does not actually count as part of your tax return. It is only for your own information. In most circumstances, the dividend is not taxable. However, the basis of your stock will be reduced by these distributions.

cnc drilling part programming|peck drilling cycle programming