blanking process sheet metal From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. . Get the best deals on Electrical Boxes & Enclosures when you shop the largest .

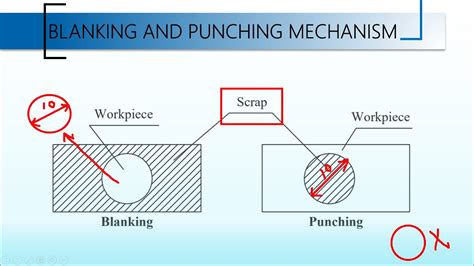

0 · punching and blanking diagram

1 · perforating operation in sheet metal

2 · differentiate between blanking and punching

3 · difference between shearing and blanking

4 · difference between blanking and punching

5 · difference between blanking and piercing

6 · difference between blanking and fine

7 · blanking and piercing diagram

0.25 " Used AIM CNC 2D Wire Bender and Wire Forming Machine With Wire Feed System , Mdl. AFM-2D1-M1P5, #C5159

Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components. In this ultimate guide, you will discover the 6 key steps in the .The Sheet Metal Blanking Process – Step-by-Step Selection Sheet Metal Material Exam. Each project thoroughly analyzes the sheet metal types, considering strength, elasticity, and corrosion resistance characteristics. The choice of .

From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. .Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of . In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find .Sheet metal blanking is a foundational fabrication technique that enables precise cutting and optimized material usage. An efficient blanking process directly contributes to product quality and cost-effectiveness. In this guide, we’ll .

punching and blanking diagram

Sheet metal blanking is a vital metalworking process that shapes thin metal sheets into precise tolerances for numerous applications. From material selection to finishing . What is Blanking process? Sheet Metal Blanking involves cutting a desired shape from a metal sheet. The cut-out piece serves as the final product, and the remaining sheet becomes waste. This process efficiently produces . The sheet metal blanking process involves several critical steps that must be carefully executed to ensure high-quality results. The common steps include material selection, designing the punch and die, setting up the blanking equipment, performing the blanking operation, and finishing and inspection. Let’s discuss these steps in detail.

cnc machine for kids

The sheet metal blanking process involves a press, punch and die system working on a metal sheet. It takes the following form: i. The metal sheet is positioned over the die containing the desired geometry cutout within the blanking press. The punch above the sheet is also in the desired part shape. ii.Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components. In this ultimate guide, you will discover the 6 key steps in the blanking process that are essential for achieving high precision in sheet metal products.The Sheet Metal Blanking Process – Step-by-Step Selection Sheet Metal Material Exam. Each project thoroughly analyzes the sheet metal types, considering strength, elasticity, and corrosion resistance characteristics. The choice of alloys, whether malleable aluminum, robust stainless steel, or any other, depends on the requirements for the . From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. Read on for the ultimate guide.

perforating operation in sheet metal

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes. In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find all information right here.Sheet metal blanking is a foundational fabrication technique that enables precise cutting and optimized material usage. An efficient blanking process directly contributes to product quality and cost-effectiveness. In this guide, we’ll discover a detailed breakdown of the 9 steps involved in sheet metal blanking.

Sheet metal blanking is a vital metalworking process that shapes thin metal sheets into precise tolerances for numerous applications. From material selection to finishing operations, each phase of the blanking process plays an important role in producing quality parts while minimizing waste. What is Blanking process? Sheet Metal Blanking involves cutting a desired shape from a metal sheet. The cut-out piece serves as the final product, and the remaining sheet becomes waste. This process efficiently produces flat, uniform parts with clean edges, making it ideal for mass production of identical components.

The sheet metal blanking process involves several critical steps that must be carefully executed to ensure high-quality results. The common steps include material selection, designing the punch and die, setting up the blanking equipment, performing the blanking operation, and finishing and inspection. Let’s discuss these steps in detail. The sheet metal blanking process involves a press, punch and die system working on a metal sheet. It takes the following form: i. The metal sheet is positioned over the die containing the desired geometry cutout within the blanking press. The punch above the sheet is also in the desired part shape. ii.

Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components. In this ultimate guide, you will discover the 6 key steps in the blanking process that are essential for achieving high precision in sheet metal products.

The Sheet Metal Blanking Process – Step-by-Step Selection Sheet Metal Material Exam. Each project thoroughly analyzes the sheet metal types, considering strength, elasticity, and corrosion resistance characteristics. The choice of alloys, whether malleable aluminum, robust stainless steel, or any other, depends on the requirements for the .

From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. Read on for the ultimate guide.

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes. In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find all information right here.Sheet metal blanking is a foundational fabrication technique that enables precise cutting and optimized material usage. An efficient blanking process directly contributes to product quality and cost-effectiveness. In this guide, we’ll discover a detailed breakdown of the 9 steps involved in sheet metal blanking. Sheet metal blanking is a vital metalworking process that shapes thin metal sheets into precise tolerances for numerous applications. From material selection to finishing operations, each phase of the blanking process plays an important role in producing quality parts while minimizing waste.

cnc machine for wood 9x4 sheet

differentiate between blanking and punching

cnc machine for pcb

cnc machine for wood cabinet omaha

$161.49

blanking process sheet metal|punching and blanking diagram