10 gauge sheet metal thickness tolerance The following charts give typical ASTM and ANSI steel sheet mechanical tolerance . Insert the dishwasher’s power cord into the electrical junction box, ensuring that the wires are organized and secure.

0 · thickness of metal gauge charts

1 · stainless steel sheet thickness chart

2 · sheet steel gauge conversion chart

3 · sheet metal screw gauge chart

4 · sheet metal gauge range chart

5 · gi sheet thickness chart

6 · gauge sheet metal thickness chart

7 · 10 gauge stainless steel thickness

Shop Whirlpool 30 inches Convertible Under cabinet Range Hood Stainless Steel at Best Buy. Find low everyday prices and buy online for delivery or in-store pick-up. Price Match Guarantee.

abs precision machining manufacturer

thickness of metal gauge charts

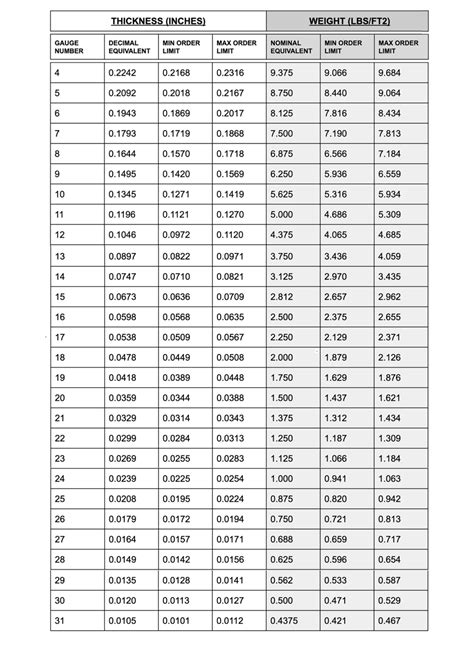

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the .The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .Tolerances: Sheet metal tolerances should not be tighter than necessary to make .

stainless steel sheet thickness chart

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

Cold rolled gages 4 through 10 tolerances shown for widths over 48" to 72" inclusive. Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other . Below is our best attempt to capture all of the standard gauge thickness of different .

Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for . The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit .

For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” .At American Metal Supply, we provide the chart to calculate thickness and sheet tolerance in inches and the weight for various gauges. Contact us to know more about our reference chart .Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.

Cold rolled gages 4 through 10 tolerances shown for widths over 48" to 72" inclusive. Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other .Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.

For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.At American Metal Supply, we provide the chart to calculate thickness and sheet tolerance in inches and the weight for various gauges. Contact us to know more about our reference chart in Cincinnati & Louisville.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.Gages 10, 11, 12 – tolerances shown are for widths over 40” to 60” inclusive All other gages – tolerances shown are for widths over 32” to 60” inclusive

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Cold rolled gages 4 through 10 tolerances shown for widths over 48" to 72" inclusive. Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other .

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.

At American Metal Supply, we provide the chart to calculate thickness and sheet tolerance in inches and the weight for various gauges. Contact us to know more about our reference chart in Cincinnati & Louisville.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.

sheet steel gauge conversion chart

sheet metal screw gauge chart

ac metal box

abilene sheet metal

$89.00

10 gauge sheet metal thickness tolerance|gi sheet thickness chart