can you use a plastic junction box The most commonly used electrical boxes are constructed of plastic but there are times a metal junction box should be used instead. Learn more. Fire Fighting Equipment. by master | Oct 10, 2016 | Rigging Hardware. .

0 · small electrical junction boxes plastic

1 · plastic wall mounted junction boxes

2 · plastic junction boxes electrical lowe's

3 · plastic junction box home depot

4 · plastic electrical junction boxes sizes

5 · plastic electrical junction boxes

6 · lowe's 12x12x4 pvc junction box

7 · large plastic electrical junction boxes

🌟 Elevate Your Manufacturing Capacity with Our Cutting-Edge Showroom Demo Machine! 🌟 Revolutionize your sheet metal bending operation and increase.

small electrical junction boxes plastic

tulsa sheet metal supply

plastic wall mounted junction boxes

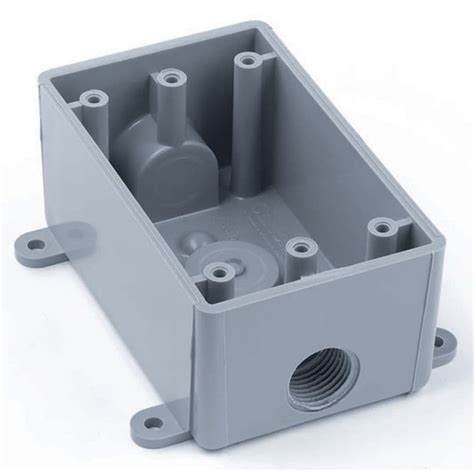

Your local electrical code may allow you to place a junction box in the attic. Check with the permitting office before you do this. Metal boxes are stronger, so they will resist damage better than plastic boxes. The third category covers junction and pull boxes (UL identification code BGYM) for use in Class I, Zone 0, 1, and 2 locations in accordance with Article 505. The information . The most commonly used electrical boxes are constructed of plastic but there are times a metal junction box should be used instead. Learn more.

Plastic junction boxes are lightweight, affordable, and resistant to corrosion. They are suitable for dry environments. Metal junction boxes are more durable, they are fire resistant and are used for wet or high-temperature areas. . Plastic junction boxes are not so sturdy, so not suitable for outside areas. They are UV rays sensitive and can even melt ( having melting points ranging from 100°C to 350°C) in some situations, therefore less durable than . Plastic boxes are designed to install 10 seconds faster - which only benefits builders. The NEC doesn't care what material, so long as it's a listed and approved junction .

Plastic junction boxes come with several benefits, especially for home use. Lightweight and Cost-Effective: Plastic boxes are easy to handle because they are light, . Electrical junction boxes made from durable, high-grade plastics are increasingly popular. What are the common pros and cons that electrical designers and contractors should be aware of when choosing whether to use .

turning a metal building into a house

The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or cables. Other types of boxes can be used . Your local electrical code may allow you to place a junction box in the attic. Check with the permitting office before you do this. Metal boxes are stronger, so they will resist damage better than plastic boxes. The most commonly used electrical boxes are constructed of plastic but there are times a metal junction box should be used instead. Learn more. You can use a plastic junction box in the attic, as long as it is accessible and open to the underlying room’s ceiling. While concealed junction boxes can be dangerous if forgotten, the accessibility requirements do not prohibit their installation in the attic.

Plastic junction boxes are lightweight, affordable, and resistant to corrosion. They are suitable for dry environments. Metal junction boxes are more durable, they are fire resistant and are used for wet or high-temperature areas. When To Use A Plastic Electric Box? Let’s review situations when you should use a plastic electrical box: Plastic junction boxes are non-conductive and don’t let the eclectic current pass through them. This feature makes it highly dependable for residential and commercial applications. Other than this, they are corrosion-resistant. This means that in damp and moist environments, they easily withstand the risk of corrosion. Plastic junction boxes are not so sturdy, so not suitable for outside areas. They are UV rays sensitive and can even melt ( having melting points ranging from 100°C to 350°C) in some situations, therefore less durable than metal junction boxes.

Electrical junction boxes made from durable, high-grade plastics are increasingly popular. What are the common pros and cons that electrical designers and contractors should be aware of when choosing whether to use plastic junction boxes? And what can Polycase’s lineup of plastic junction boxes offer for today’s electrical applications? We .

The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or cables. Other types of boxes can be used as junction boxes.

Plastic junction boxes are easy to install in many situations. They’re easiest to install during new construction when the wall studs or ceiling joists are exposed. You simply hold the box against the wood framing and drive the two nails that come pre-attached to the box.

Plastic junction boxes come with several benefits, especially for home use. Lightweight and Cost-Effective: Plastic boxes are easy to handle because they are light, making them perfect for DIY jobs. They are also more affordable than metal boxes, which helps if .

Your local electrical code may allow you to place a junction box in the attic. Check with the permitting office before you do this. Metal boxes are stronger, so they will resist damage better than plastic boxes. The most commonly used electrical boxes are constructed of plastic but there are times a metal junction box should be used instead. Learn more. You can use a plastic junction box in the attic, as long as it is accessible and open to the underlying room’s ceiling. While concealed junction boxes can be dangerous if forgotten, the accessibility requirements do not prohibit their installation in the attic. Plastic junction boxes are lightweight, affordable, and resistant to corrosion. They are suitable for dry environments. Metal junction boxes are more durable, they are fire resistant and are used for wet or high-temperature areas. When To Use A Plastic Electric Box? Let’s review situations when you should use a plastic electrical box:

Plastic junction boxes are non-conductive and don’t let the eclectic current pass through them. This feature makes it highly dependable for residential and commercial applications. Other than this, they are corrosion-resistant. This means that in damp and moist environments, they easily withstand the risk of corrosion.

Plastic junction boxes are not so sturdy, so not suitable for outside areas. They are UV rays sensitive and can even melt ( having melting points ranging from 100°C to 350°C) in some situations, therefore less durable than metal junction boxes. Electrical junction boxes made from durable, high-grade plastics are increasingly popular. What are the common pros and cons that electrical designers and contractors should be aware of when choosing whether to use plastic junction boxes? And what can Polycase’s lineup of plastic junction boxes offer for today’s electrical applications? We . The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or cables. Other types of boxes can be used as junction boxes.

Plastic junction boxes are easy to install in many situations. They’re easiest to install during new construction when the wall studs or ceiling joists are exposed. You simply hold the box against the wood framing and drive the two nails that come pre-attached to the box.

Shop Wayfair for the best adjustable junction box vanity light. Enjoy Free Shipping on most stuff, even big stuff.

can you use a plastic junction box|plastic junction boxes electrical lowe's