cnc machine chucks Royal CNC Collet Chucks are available in two main styles – our Low-Profile series .

An Array Junction Box, AJB, is used to connect the photovoltaic strings in parallel. The combined DC power is fed to the photovoltaic inverter. It includes photovoltaic string protection, overvoltage protection and a DC output switch isolator.

0 · what is solid chuck

1 · what is a chuck engineering

2 · types of collet chucks

3 · strong lathe chucks

4 · replacement chucks for cnc machines

5 · power chucks for cnc lathes

6 · kitagawa chuck catalogue

7 · chuck jaws for kitagawa

The most important thing when welding a thin sheet with MIG is to use the smallest diameter wire as this will give the minimum heat input for welding. Also, small diameters run quite well with short-circuit mode , which is very good for thin sheets welding.

Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ .Royal Products has been a leading American manufacturer of metalworking .

For over 75-years, leading manufacturers have trusted Royal Products to help .

Videos - Royal Products Home – Royal ProductsLiterature - Royal Products Home – Royal Products

Royal CNC Collet Chucks are available in two main styles – our Low-Profile series .QG-52 CNC Collet Chucks & Fixtures. Royal has added a full range of QG-52 .

what is solid chuck

How to Buy - Royal Products Home – Royal Products

Royal CNC Collet Chucks are available in two main styles – our Low-Profile series utilizes traditional 5C, 3J, and 16C spring-style collets, while our revolutionary Quick-Grip™ series offers ten-second collet changes, an .Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.

A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed .

In our offer you will find only truly European, durable and high-quality products, including: manual and power lathe chucks, cylinders, precision machine vises, milling fixtures, VDI toolholders, spindle tooling and quickchange toolposts, .

what is a chuck engineering

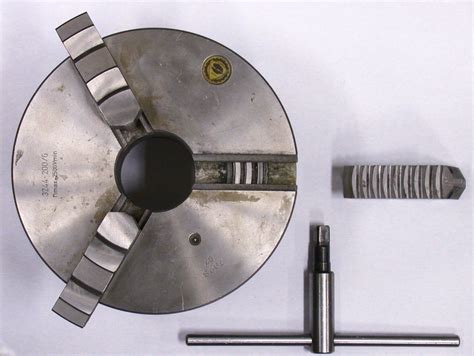

Choose from our selection of three-jaw lathe chucks, chuck stops, 5C collet to lathe chuck adapters, and more. In stock and ready to ship.

Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all turning jobs up to 4” diameter.Royal CNC Collet Chucks are available in two main styles – our Low-Profile series utilizes traditional 5C, 3J, and 16C spring-style collets, while our revolutionary Quick-Grip™ series offers ten-second collet changes, an industry-leading gripping range, and parallel-grip functionality for superior workpiece engagement and rigidity.

Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed by the CNC machine.

In our offer you will find only truly European, durable and high-quality products, including: manual and power lathe chucks, cylinders, precision machine vises, milling fixtures, VDI toolholders, spindle tooling and quickchange toolposts, manufactured using advanced technologies.Choose from our selection of three-jaw lathe chucks, chuck stops, 5C collet to lathe chuck adapters, and more. In stock and ready to ship.

A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without slipping or vibrating.A CNC chuck, also known as a lathe chuck, is a specialized device used in computer numerical control (CNC) machining. It is an essential component of a lathe machine and is used to securely hold and rotate the workpiece during machining operations.Techniks Collet Chucks deliver excellent performance in a wide range of CNC machining applications including milling, drilling, and tapping.National Machine Products has partnered with TDG Clamping Solutions to provide a range of large diameter chucks that help optimize CNC machining production. TDG is a leading provider of innovative clamping solutions that have been designed to meet the ever-changing needs of modern machining.

types of collet chucks

Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all turning jobs up to 4” diameter.Royal CNC Collet Chucks are available in two main styles – our Low-Profile series utilizes traditional 5C, 3J, and 16C spring-style collets, while our revolutionary Quick-Grip™ series offers ten-second collet changes, an industry-leading gripping range, and parallel-grip functionality for superior workpiece engagement and rigidity.

Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed by the CNC machine.In our offer you will find only truly European, durable and high-quality products, including: manual and power lathe chucks, cylinders, precision machine vises, milling fixtures, VDI toolholders, spindle tooling and quickchange toolposts, manufactured using advanced technologies.Choose from our selection of three-jaw lathe chucks, chuck stops, 5C collet to lathe chuck adapters, and more. In stock and ready to ship.

A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without slipping or vibrating.A CNC chuck, also known as a lathe chuck, is a specialized device used in computer numerical control (CNC) machining. It is an essential component of a lathe machine and is used to securely hold and rotate the workpiece during machining operations.Techniks Collet Chucks deliver excellent performance in a wide range of CNC machining applications including milling, drilling, and tapping.

how to tell if electrical box is grounded

how to tell if electrical box is grounded

Perforated metals are sheets of metal that have had decorative shapes and holes punched or stamped into their surface for both practical and aesthetic purposes. The perforation process can create a variety of geometrical patterns and designs, .

cnc machine chucks|kitagawa chuck catalogue