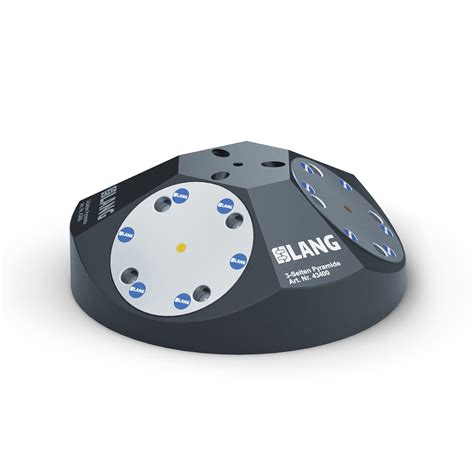

cnc machine clamping systems For applications CNC machining centers and manual machines, we recommend Clamping Systems 5000, 8000, and 9000. Palletized workpieces, electrodes, or fixtures in various . Black or stainless steel faucets exude modernity, while gold tones infuse a touch of opulence. Choose the finish that resonates with your vision and ties into the broader design narrative. Unleash your creativity when designing your kitchen island.Here are granite colors that pair perfectly with white cabinets. The industrial-chic look is trendy these days, and the trendy Steel Grey Granite, sometimes referred to also as Silver Pearl Granite, is the epitome of that .

0 · zeroclamp zero point clamping system

1 · zero point workholding clamping systems

2 · schunk zero point clamping system

3 · oops clamps for cnc

4 · material clamping and holding systems

5 · cnc chuck clamping troubleshooting

6 · clamping systems for cnc mills

7 · clamping round parts on mill

The choice between bed slats and box springs depends on your mattress type and specific needs. Bed Slats: Bed slats are a foundation type consisting of long planks made of wood or metal, spaced closely together. They provide even support for various mattress types and promote airflow, reducing the risk of moisture buildup.

From hydraulic/pneumatic clamps for heavy-duty applications to versatile block/combination clamps for varying workpiece configurations, the array of CNC machine workpiece clamping caters to the intricacies of modern .For applications CNC machining centers and manual machines, we recommend Clamping Systems 5000, 8000, and 9000. Palletized workpieces, electrodes, or fixtures in various .A comparison of 8 different types of clamping systems for CNC milling based on safety, cost, ergonomics, adaptability and compatibility with different working areas. From hydraulic/pneumatic clamps for heavy-duty applications to versatile block/combination clamps for varying workpiece configurations, the array of CNC machine workpiece clamping caters to the intricacies of modern machining.

For applications CNC machining centers and manual machines, we recommend Clamping Systems 5000, 8000, and 9000. Palletized workpieces, electrodes, or fixtures in various dimensions and demands for accuracy are clamped precisely and with a .We offer you the best solutions for your workpieces for the best results in clamping technology. SCHUNK offers you a flexible range of diverse options from one source for machining different workpiece geometries.

The trusted global leader in workholding fixture solutions for CNC machining centers and milling machines. As the original inventor of the wedge-operated Low-profile Clamp, OK-VISE® has been at the forefront of fixturing innovations for years.

A well-set clamping system is a key factor in achieving dimensional accuracy in finished parts produced by CNC machines. Achieving this precision entails choosing the right clamping system,proper positioning,and correct clamping pressure.Quick•Point® is a purely mechanical clamping system in which a rod system inside the zero-point plate ensures a repeatability of 0.005 mm. The technical design with one tightening screw makes the operation of the zero-point plates very easy.Fast, precise clamping and referencing of devices and components on EDM machines, all metal cutting machine tools, CNC machining centers, and measuring equipment. Experience higher productive machining time due to the full-time parallel setup of fixtures and workpiece blanks on universal (even automatic) exchangeable pallets and holders.Choose the industry’s most powerful clamping system featuring the OTT-JAKOB patented force intensifying mechanism for maximum tool retention force within a compact system. AME is the full-service partner for all OTT-JAKOB products in North America.

The ZeroClamp zero point clamping system is the modern alternative to the conventional T-slot table: Drastically reduces the setup times and increases your machine capacity. Repeat accuracy of less than 2.5 μm. Just one type of clamping stud. Thermal symmetry. Uncomplicated joining and removing. Milling, turning, right up to quality assurance. 1.A comparison of 8 different types of clamping systems for CNC milling based on safety, cost, ergonomics, adaptability and compatibility with different working areas. From hydraulic/pneumatic clamps for heavy-duty applications to versatile block/combination clamps for varying workpiece configurations, the array of CNC machine workpiece clamping caters to the intricacies of modern machining.For applications CNC machining centers and manual machines, we recommend Clamping Systems 5000, 8000, and 9000. Palletized workpieces, electrodes, or fixtures in various dimensions and demands for accuracy are clamped precisely and with a .

We offer you the best solutions for your workpieces for the best results in clamping technology. SCHUNK offers you a flexible range of diverse options from one source for machining different workpiece geometries.

The trusted global leader in workholding fixture solutions for CNC machining centers and milling machines. As the original inventor of the wedge-operated Low-profile Clamp, OK-VISE® has been at the forefront of fixturing innovations for years.A well-set clamping system is a key factor in achieving dimensional accuracy in finished parts produced by CNC machines. Achieving this precision entails choosing the right clamping system,proper positioning,and correct clamping pressure.Quick•Point® is a purely mechanical clamping system in which a rod system inside the zero-point plate ensures a repeatability of 0.005 mm. The technical design with one tightening screw makes the operation of the zero-point plates very easy.Fast, precise clamping and referencing of devices and components on EDM machines, all metal cutting machine tools, CNC machining centers, and measuring equipment. Experience higher productive machining time due to the full-time parallel setup of fixtures and workpiece blanks on universal (even automatic) exchangeable pallets and holders.

Choose the industry’s most powerful clamping system featuring the OTT-JAKOB patented force intensifying mechanism for maximum tool retention force within a compact system. AME is the full-service partner for all OTT-JAKOB products in North America.

1976 mercedes 450sl sheet metal

zeroclamp zero point clamping system

zero point workholding clamping systems

You can create new sheet metal parts from a template that has predefined attributes, including material, bend relief, bend radius, corner relief, gap values, punch representations, and unfolding rules. Sheet metal-specific commands streamline work on both the folded and unfolded model.

cnc machine clamping systems|clamping systems for cnc mills