cnc manufacturing degrees CNC Machining & Programming II ; CAD/CAM ; Quality Control with GD&T ; Perspectives Perspectives are points of view, offering a variety of ways of understanding, interacting, and influencing the world. . Preston is seeking a . Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

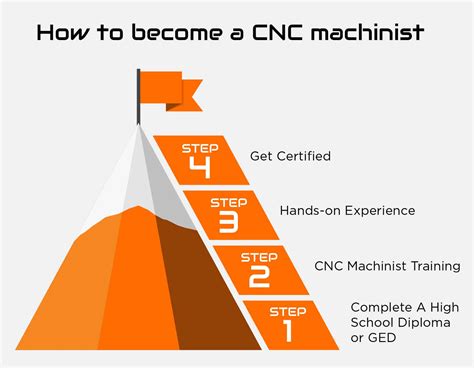

0 · how to get cnc certified

1 · how to become cnc operator

2 · how to become cnc certified

3 · cnc qualification

4 · cnc entry level job training

5 · cnc degree programs

6 · cnc degree near me

7 · cnc certification

Get inspired with Ideas, Designs and Pictures for building your DIY Welding Table or Cart. See how others have handled storage for welding machines, rods, gas tanks, angle .

In contrast to manual machining, manufacturing companies can use CNC machine tools to automate and streamline their manufacturing processes. With CNC machines, trained operators can oversee more than one .

Smart manufacturing practices are on the rise. And the demand for skilled machinists is higher than ever. At Penn College, you’ll train within an industry-driven curriculum. Master CNC .CNC Machining & Programming II ; CAD/CAM ; Quality Control with GD&T ; Perspectives Perspectives are points of view, offering a variety of ways of understanding, interacting, and influencing the world. . Preston is seeking a .

With over 100 degrees and certificates in a wide range of academic and career and . Students will learn automated manufacturing processes that involve up-to-date technologies to improve production of products from the design to manufacturing stages. . (NCCER), OSHA-30 Construction Safety Card, Drafting, CNC Certificates: Basic Machining and .

For new machinists seeking CNC degrees, top picks include Associate of Applied Science (AAS) in CNC Technology, Certificate in CNC Programming, and Bachelor of Science in Manufacturing Engineering .The Manufacturing program will help transform you into an invaluable asset by teaching you essential skills like process design, QA, quality control, computer numeric control (CNC) machine set-up and operation, computer-aided design (CAD), and .Earn free college credits toward your Associate's Degree in Advanced Manufacturing while learning the skills employers are looking for right now in this two-phase advanced manufacturing boot camp. Phase 1: Earn 13 college credits in this 19-week program that introduces the fundamentals of manufacturing, safety, precision measurement and .

While few and far between, educational certificates can be an effective tool to hone your abilities and competence. As such, pursuing a formal educational program, such as the CNC Machining training programs at Goodwin, can advance your career and prepare you for higher-level tasks, additional responsibilities, and better job security.Designed to give students modern manufacturing skills, knowledge, and abilities required to enter the workforce. Also intended for entrepreneurs seeking the fundamental skills to get started in modern manufacturing. A certificate is designed to provide career technical skills; it is not equivalent to an associate degree. Learn more.Develop programs to control machining or processing of materials by automatic machine tools, equipment, or systems. May also set up, operate, or maintain equipment. . The CNC Manufacturing Technician Program provides instruction in the programming, set up and operation of CNC Machine tools such CNC Turning Centers and CNC Machining Centers .

Full CNC machinist degree programs are offered by technical colleges and typically take two academic years to complete. These programs entail educational classes and industry-specific courses to prepare students for the job market. Ordinarily, educational programs cover subjects such as engineering, maths and computer technology. Formulas for Converting Degrees per minute to inches (millimeters) per minute. Inches per minute = Degrees per minute * Diameter / 114.5916 Millimeters per minute = Degrees per minute * Diameter / 114.5916 Example #3: 4000 Degrees per minute, Cutting 2 Inch Diameter Inches per minute = 2000 * 2 / 114.5916 Inches per minute = 4000 / 114.5916 Consider a tool with a 5 inch gauge length. The CTE of HSS is something like 6 millionths per inch per degree F, no? So 1 degree F is 30 millionths in the length of that tool. 3 degrees F is effectively 100 millionths or 1/10th of a thou. Is the temperature of your tool really constant to within 3 degrees F? From tool changer to cutting?In the precision machining A.A.S. program at Monroe Community College, you’ll get first-hand experience in the most current machining techniques and technology. You’ll work in one of the best-equipped college machining programs in New York State while learning from journeyman machinists with years of professional experience.

CNC manufacturing and machining labs are housed in the state-of-the-art Sustainable and Advanced Manufacturing Center. For adult learners living in the Buffalo area, ASC also offers the CNC manufacturing and machining AOS degree in Buffalo at the Northland Workforce Training Center. Founded in 2018, the east-side Buffalo Northland facility .Our Associate degree and certificate programs prepare you for entry-level employment in high-demand jobs such as general machinist, tool-and-die maker, mold maker, special machine builder, maintenance machinist, computer-aided manufacturing technician, computer numerical control (CNC) operator or programmer, set-up specialist, industrial sales .

how to get cnc certified

Shape your future with machining courses in Computer Numerical Control (CNC). Today’s manufacturing facilities and machinist shops rely on advanced manufacturing technology, advanced design software, programming skills, . Tormach announced its plans to invest in Career and Technical Education (CTE) programs by developing a comprehensive CNC metal milling curriculum and introducing a new 4th axis for its xsTECH Tabletop CNC . How long is CNC training? It commonly takes 9 to 24 months to complete a program at a CNC machining school.*. What education do I need to become a machinist? Certificate programs typically take up to a year to .CNC Machining II: Pathway Map: Associate Degree. . Develop programs to control machining or processing of materials by automatic machine tools, equipment, or systems. May also set up, operate, or maintain equipment. Typical Education Level. a .

china cnc plasma manufacturer

Programs Discover what degrees, certificates and credentials you can earn from a career/technical program at TCC. Program Finder. . Career Studies Certificate - Basic Machining. Basic metal and plastic machine operators adjust machines to control speed, material feed, and path of the cut, and ensure the machines are set up and operating .For many of Coursera’s programs, no previous experience is required. CNC machining training is categorized by the following levels: beginner, intermediate, and advanced. If you’re brand new to the industry, you might consider starting with a beginner-level CNC course and working your way up to intermediate.

CCL/5647 CNC Machining II CCL/5795 CAM Systems Programming. What You’ll Learn. . Education requirements vary for the occupations listed below, so you may need further education or degrees in order to qualify for some of these jobs and earn the related salaries. Please visit with an academic advisor and/or program director for additional .

china cnc precision machining services suppliers

how to become cnc operator

The training for CNC machinist courses begins with an introduction to CNC machining, where you will work toward establishing a strong foundation in the principles and practices of CNC machining. The courses will cover crucial aspects such as machine setup and operation, enabling you to operate CNC machinery with confidence and precision.CNC (Computer Numerical Control) Machining uses computers to control tools, such as lathes, mills, routers and grinders. These machines are programmed to produce precise components used in a variety of products. Programming can be done using CAD/CAM (Computer Aided Design/ Computer Aided Manufacturing) programs and are loaded into the CNC control.Mt. San Antonio College offers multiple options to enter the innovative world of Manufacturing. Students can choose between an associates degree and four certificates to prepare students to work in the fast paced environment of the industry. Earning a Certificate takes less time than an Associate Degree, and provides a stepping stone for students to quickly gain skills and .

Degree for sure. Start with an Associates in Mechanical, Manufacturing, Automation Engineering at a community college that can transfer to a reciprocal 4-year degree. I'm the opposite of you right now. I Was in machining for 5 years got a precision machining cert. decided I wanted to be in the office and do CAD design engineering.

Utilizing hands on learning, the Machine Tool Technology Program trains students in the use of manually operated machine tools as well as the latest in Computer Numerical Control (CNC) machine tools. This allows students the chance to learn how to . The screw hole in the center is .3125" in diameter with an 82 degree counterbore that goes to the edge of a 3/4" counterbore tool. I suspect the issue is the disparity between the center hole and the edge of the counterbore, and trying to get the feeds and speeds right. . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million .

how to become cnc certified

CNC welding machines utilize computer programming and advanced robotic mechanisms to perform welding tasks with unparalleled accuracy and consistency. The process starts with CAD or CAM software, where the desired weld design is created. This design is then converted into a machine-readable format.

cnc manufacturing degrees|cnc degree near me