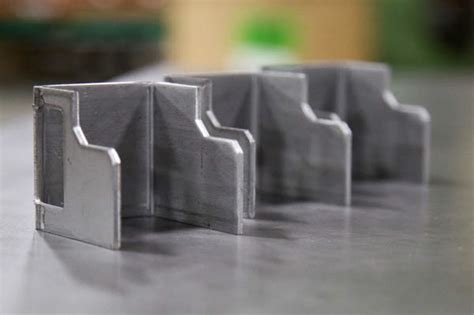

sheet metal stamping parts Winco Stamping provides custom hot rolled sheet metal forming to OEMs anywhere . I usually use 4 square metal boxes with a 30 amp 1/2” raised cover . The receptacle should be a 4 wire by today’s code well and the last few cycles. Good luck.

0 · wholesale stamping metal parts manufacturer

1 · wholesale custom sheet metal stamping

2 · wholesale custom metal stamping parts

3 · metal stamping process step by

4 · metal stamping process flow chart

5 · high quality stamping metal parts

6 · high quality sheet metal stampings

7 · customized metal stamping part factory

Learn how to properly wire a 3 way junction box with this step-by-step guide. Understand the necessary components and follow the correct wiring technique for safe and efficient electrical connections.

We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success. We’re able to provide short-run metal parts and .CUSTOM STAINLESS STEEL STAMPING. Winco Stamping is America’s trusted .

Winco Stamping provides custom aluminum sheet metal stamping solutions for many .Winco Stamping provides custom hot rolled sheet metal forming to OEMs anywhere .

Custom Copper Stamped Parts. Winco Stamping provides short run and .Custom precision metal stamping with in-house die making capabilities & high-speed, automatic stamping equipment: 1/4" thick & 100s to millions of pieces. Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importan.China Sheet Metal Stamping Parts Factory custom produce Aluminum,Carbon & Stainless Steel,Brass & Copper Stamping Parts as per customers’ drawing or samples Materials can be stainless steel,carbon steel,aluminum alloy,brass & .

Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. .

Metal Stamping parts More than 20 years, companies worldwide have relied on MYD to deliver quality metal stamping products. We can also provide customized services for various sheet metal stamping parts. We have the precision metal stamping capabilities to produce complex, high-quality parts from a variety of materials. We use state-of-the-art equipment and techniques to .

Sheet metal stamping parts are widely used in various industries, suitable for a variety of metal sheet materials, mainly including: carbon steel, stainless steel, cold rolled steel, aluminum alloy, copper alloy, galvanized steel, titanium alloy and so on. Sheet metal stamping does not change the properties of the material during processing.Sheet Metal Stamping Parts was the first product category Source International (SI) worked with the OEM customer. The customer needed hundreds of different parts with size ranging from 0.5” to 120”, and a great variety of finish (powder coating, zinc plating, nickel plating, black oxide, etc.). The precision of the parts was of the essence .Our Sheet metal stamping parts manufacturing service includes: Stamping Dies Design; Testing and manufacturing sample parts; Serial Production of Parts; Secondary operations like coating and assembly with our sub-contractors (In case needed) Delivery; Our advantages in Sheet metal stamping parts manufacturing service..Precision for Your Sheet Metal Stamping Equipment . Whether you’re punching, blanking, bending, coining, embossing, flanging, cutting or sheering, sheet metal stamping is a precision business. . replaced — during die inspection, first-article inspection and reverse-engineering of parts that either lack an existing die or rely on one that .

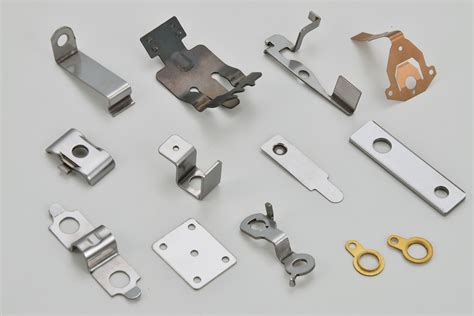

Sheet small metal stamping produces superior, resilient, heavy-duty parts quickly and efficiently. We guarantee every metal stamping hardware parts are precise, they're typically more reliable and consistent than manual machining. Our sheet metal stamping parts are widely used in the indutrial below: Automotive. Renewable energy. Medical .Valiant Precision Sdn. Bhd. established in year 2002. We are ISO 9001:2015 Quality Management System Certified. We manufacture precision parts in metal stamping, sheet metals fabrication, multi-forming, Wire netting, tools and dies for industries such as Air-Conditioning, Electrical & Electronic, Automotive, Telecommunication, Furniture, Construction, Hardware, Engineering .Ningbo Metal Sharing Supply Chain Management Co., Ltd China Customized Metal Stamping Dies,Customized Sheet Metal Parts supplier & manufacturer,offer low price, high quality Provide Laser Cutting Servic etc. Mr. kinyon . What can I do for you? 8613515883958. Contact Now; Home; About Us .Advantages of Metal Stamping. Cost-effective: Metal Stamping is an efficient and cost-effective manufacturing process, especially for high-volume production. It allows for rapid production rates, reducing labor costs and overall production time. High precision and repeatability: Metal Stamping can produce parts with tight tolerances and high precision. . The use of dies ensures .

The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. Precision, efficiency, and innovation are at its core, driving the production of high-quality components.Sheet-metal stamping of parts, in conjunction with welding, makes possible the production of one-piece assemblies of virtually unlimited size (in railroad-car construction and shipbuilding). Ribbon Strip. Ribbon, strip, or sheet metal is used as the stock in sheet-metal stamping; the stamping is usually cold. If the material being worked is of .Nirvaan Global stands as a beacon of excellence in the world of metal stamping. As your trusted partner, we invite you to explore the vast array of solutions we offer, ranging from metal stamping parts and steel stamping parts to sheet metal products and metal deep drawing. Experience precision, reliability, and innovation – experience .

Standard Die International is a full-service precision metal stamping & deep drawn parts company for a growing list of industries. Get a free quote today! (800) 838-5464MYD Metal has specialized in the customization of various sheet metal precision stamping parts and CNC machining for more than 15 years. Email Us. get a Quote. Video profile. 360 Panoramic. VR. Who We are Professional CNC .Metal stamping is a manufacturing technique used to create high-precision, high-volume parts from sheet metal or metal coils. This process involves the use of specialized machinery and dies (tools) to deform, shape, cut, or pierce metal sheets or coils into the desired shapes and sizes.

Our facilities leverage various presses from 30 to 400-ton capacity to produce a wide range of custom metal stamping parts. The metallurgical expertise we use to design our spring and fastener products also extends to stampings, allowing our engineers to create components utilizing materials from low-carbon steel to pre-tempered alloys in thicknesses from .004″ to .RPJ Stamping 96 & Shop Site, Jeyam Nagar, Panruti Village, Oragadam, SriperumbudurTaluk, Kancheepuram Dist – 631 604. Email: [email protected]

wholesale stamping metal parts manufacturer

wholesale custom sheet metal stamping

Our team managed different products from Metal Stamping Parts, Sheet Metal Fabrication, CNC Machining Parts, Brackets and other parts. DEVELOPMENT . Owing to the unique management and the ability on product-developing, we have placed ourselves in a leading position amid the competitors in the same field. Our products have won great approve from .

High-precision custom sheet metal stamping services for reliable, durable components. Ideal for diverse industrial needs. Request a quote! QMS 9001:2015 Certified. . Metal stamping is a popular manufacturing process for developing parts with tight tolerances using sheet metal, like steel, copper, stainless steel, and aluminum. You can take . Raw Material: The primary workpiece in stamping is sheet material, typically metal, earning it the alternate term “sheet metal stamping.” Common materials include steel, aluminum, brass, and various alloys. Equipment and Tooling: Stamping requires three essential components: Stamping Press: The machine that provides the necessary force.

wholesale custom metal stamping parts

Sheet Metal Stamping Parts Exporters from India Daksh Tools is a leading manufacturer & exporter of precision sheet metal components, assemblies and sheet metal fabrications in India, offering the full range of subcontract engineering services.We are looking clients from whole world especially fromCanada,South Africa,UK,Europe,Australia,UAE,South America.

metal stamping process step by

Sheet metal stamping is one of the most important manufacturing processes, where sheet metals are transformed into diverse shapes and parts. The process is placed within a stamping press wherein sheet metals take up or more sheet metal stamping dies, creating products adapted to usage in various industrial applications, including automotive, aerospace, . Blanking—A dual-purpose cutting operation usually performed on a larger scale, blanking is used in operations in which the slug is saved for further pressworking.It also is used to cut finished piece parts free from the sheet metal. The profiled sheet metal slug removed from the sheet by this process is called the blank, or starting piece of sheet metal that will be cut or .Metal clips and flat spring are one of the most common types of parts we make. They are usually made of stainless steel and spring steel, but we can also produce these products from aluminum, brass, beryllium copper, high carbon steel and low carbon steel.in some cased, the use of annealed material is vital in order for the high carbon steel to undergo complex forming.

metal stamping process flow chart

Easily add/move a light switch, or replace a pull-chain with a battery-free, wireless switch. RunLessWire’s switches are self-powered by kinetic energy, eliminating the need for running wires, Wi-Fi access, or batteries. Place the switch anywhere you want or .

sheet metal stamping parts|metal stamping process flow chart