titanium cnc precision machining factories Improve your application with titanium parts or assemblies from Moon Tool & Die Co. We are an ISO 9001:2015-certified CNC machine shop specializing in the . $95.00

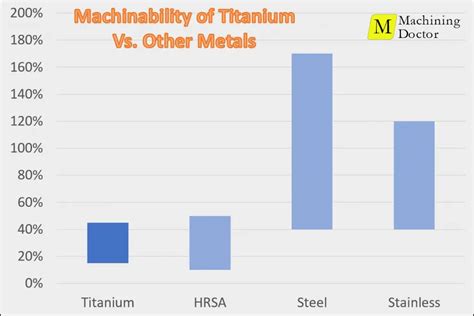

0 · titanium machinability chart

1 · recommended cutting speeds for titanium

2 · machining titanium without coolant

3 · is titanium hard to cut

4 · is titanium difficult to machine

5 · does titanium bend when machining

6 · best way to cut titanium

7 · best end mill for titanium

Some use external software, I use elum tools, which is a Revit add-in and can do that with the power of the families. (Revit already can do lighting power density natively, so you can verify code compliance in real time)

Improve your application with titanium parts or assemblies from Moon Tool & Die Co. We are an ISO 9001:2015-certified CNC machine shop specializing in the .RAM Tool provides a range of CNC machining services that can be applied to titanium alloys. Our 5-axis machining, CNC milling, CNC boring, CNC grinding, EDM, and additional custom metal . Custom CNC services enable manufacturers to achieve tighter tolerances for the strength, weight, and appearance of cnc parts since various metals for cnc machining and finishes are offered. Additionally, they assist with rapid prototyping and large-scale bastow production, which allows innovation while claiming that the components meet industry .With over 65 CNC mills and lathes, we provide Ultra Precision for low volume, repeat machining to the micron level of accuracy, with tolerances within 0.00005”. Our precision machining is supported by world-class quality departments, .

Precision titanium CNC machining services for a diverse range of applications. Capable of producing machined titanium parts from 2 inches to over 100 feet. . Titanium CNC machining is a precise manufacturing process that involves the .Understanding common materials used in precision CNC machining is essential for both manufacturers and engineers, as each material brings its unique properties and applications to the table. Let’s take a closer look at a few: Aluminum. Lightweight yet durable, aluminum is one of the most popular materials in precision CNC machining.It’s known for its excellent . Explore the essentials of titanium CNC machining in our A-Z guide. Get expert tips on techniques, tools, and applications for precision results. . Automotive manufacturers use titanium to reduce fuel consumption by reducing weight (i.e., lightweighting) by using titanium to replace heavier steel parts. Titanium is used in valves and valve .Titanium CNC machining is a specialized manufacturing process used to create high-precision parts from titanium alloys. Known for its strength, durability, and corrosion resistance, titanium is widely used in industries such as aerospace, medical, automotive, and marine.

A Reliable Titanium Fabrication Supplier-AS PRECISION. . In order to create a worldwide manufacturing system, in 2019 we launched a CNC machining components factory overseas in Vietnam, modernizing our infrastructure and services for the global market. How Titanium Milling Work - And What It Means For Your Business .The Matsuura MAM72 100H is a 5-axis CNC machining center designed for precision work in industries like aerospace, healthcare, and automotive manufacturing. It functions by coordinating multiple axis movements to achieve intricate component geometries and high accuracy.Why use Precision Titanium Machining from Forster Tool?. Since 1958, Forster Tool has been providing custom machined titanium parts using our core titanium machining services. Forster Tool provides Swiss Screw Machining, Swiss Turning and Precision Milling of titanium parts. Our experienced machinists have the knowledge and are always fashioning new ways to better .PRECISION CNC MACHINING GETS SUPERIOR RESULTS FAST. Arbiser Machine has top of the line equipment and CNC machining capabilities. Features like multiple axis on equipment, wireless communication and connection to some of the best in class software speed up automation and adjustments, to help us meet deadlines and turn around projects quickly.

titanium machinability chart

Tolerances Wall Thickness Max Part Size Lead Time; The achievable machining tolerances depend on the specific type of Titanium being used, but typically a tolerance of 0.005 inches can be achieved.: It is possible to achieve a minimum wall thickness of 0.03 inches (0.8mm), although this may vary based on the ratio of wall thickness to planar dimension as well as the specific .

Common Uses of Titanium Alloy Machining. Titanium machining finds application across diverse industries: Aerospace: Used for aircraft components such as engine parts, landing gear, and structural components due to its strength-to-weight ratio.; Medical: Essential for manufacturing surgical implants and instruments due to its biocompatibility and corrosion .Titanium is a very sturdy metal, but it is also extremely difficult to machine. We are one of the few companies that can work with titanium, meaning you don’t have to look for a different company who specializes in CNC machining titanium. We are able to create complex parts that are made of titanium that would be impossible for any other company. This material requires special .

Benefits of CNC Machining for Aerospace Applications. CNC machining is ideal for aerospace because it’s accurate, fast, and affordable. It delivers high-quality parts quickly and at a lower cost than other methods. Increased Accuracy. CNC machining ensures precise, consistent parts, essential for aerospace components like titanium parts.Whether you need machining services for complex prototypes, finished components, or assembled parts, Momentum Manufacturing Group can support your needs. With 200+ CNC machines across 7 locations and an experienced .The precision offered by CNC machining and Swiss precision machining ensures that each part meets the exacting standards required by military specifications. Whether it’s a component in an armored vehicle or a fastener in an aircraft, the part must perform flawlessly under pressure.Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM

recommended cutting speeds for titanium

The Mighty Viper VT23 is a CNC vertical machining center. It operates through a computer numerical control system, facilitating precise machining processes. Widely used in aerospace, automotive, and precision engineering industries, this machine can process materials such as aluminum, steel, and titanium. Mighty Viper VT23 Specifications and .

Contents hide 1 Unveiling the Secrets to Achieving High-Quality CNC Machined Titanium Products 2 CNC Machining Basics 2.1 What is CNC Machining? 2.2 Why Choose Titanium? 3 The CNC Machining Process 3.1 The Fundamental Steps of CNC Machining 3.1.1 Step 1: Design and CAD Modeling 3.1.2 Step 2: Toolpath Planning 3.1.3 Step 3: Material Fixturing [.]Importance of CNC Machining in Modern Manufacturing. CNC (Computer Numerical Control) machining plays a crucial role in modern manufacturing processes, particularly when working with materials like titanium. Here are some key reasons why CNC machining is important: Precision: CNC machines can produce parts with extremely high levels of accuracy .

steel boxes for keys

Metal Parts CNC Precision Machining Factory. SKY-CNC is a metal parts CNC precision machining manufacturer. We have 20+ years of industrial design and 10+ years of CNC machining experience, so we have a better understanding of products and OEM/ODM parts, to ensure your ideas and projects are brought to market quickly and on-time.Delivering a titanium project on spec, on time and on budget is one of the toughest challenges in the machining industry. The experts at Cox Manufacturing have learned, through decades of experience, the productivity secrets needed to inspire complete confidence in the users of top quality titanium CNC machining.

CNC precision machining titanium parts The cost-effectiveness analysis of CNC customized processing of titanium and titanium alloy parts is as follows: Material cost: The price of titanium and .precision custom CNC machining services to companies in Europe and North America since 2015. . Custom CNC Machined Stainless Steel Parts Swiss-Type Turning. Custom Precision CNC Machining Ti-6Al-4V titanium parts. Custom Precision Sheet Metal Bending Audio Equipment Panel With Powder Coating . automotive, electronics, industrial automation . Materials Can Be Used In CNC Precision Machining. Stainless Steel; Bronze, Brass, Copper; Plastic(ABS, PC, PMMA.) Aluminum; Titanium; CNCfirst: The Precision CNC Machining Company You’ve Been Searching For. CNCfirst is a precision CNC machining company that provides high-quality and accurate parts and components to its customers.

Ardel Engineering offers superior titanium CNC machining services to industries that prefer tougher metals in their projects. Learn how we can help you today! Skip to Content. 888.483.9924. . Ardel Engineering stands at the forefront of precision manufacturing, offering state-of-the-art machining services through vertical and horizontal CNC .The Hermle C 650 is a 5-axis CNC machining center. Designed for precision, the C 650 is used in industries such as aerospace, automotive, and mold manufacturing. . ideal for industries like aerospace, automotive, and mold-making. Able to work with materials such as titanium, aluminum, and stainless steel, this machine serves various high .

machining titanium without coolant

is titanium hard to cut

is titanium difficult to machine

does titanium bend when machining

Compact and portable with removable cable, this M.2 SSD Enclosure is with you when you need it. Features a sleek black design, aluminum heatsink with low-profile cooling fins. Compatibility —Install an M.2 NVMe SSD 2230, 2242, 2260, or 2280 (not included), PCIe Gen 3 or PCIe Gen 4, of any capacity.Suitable for all 12.7mm SATA optical drive core installation, Support 1.5Gbps SATA I and 3.0Gbps SATA II interface standard. Wide Compatibility: support .

titanium cnc precision machining factories|titanium machinability chart