countersink thin sheet metal Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything . Hộp nối loadcell (Junction Box) JXH-4/6/8. Hộp nối JXH với 2 tùy chọn, chỉnh nguồn hoặc tín hiệu. Là sản phẩm chất lượng cao do Yaohua/Zemic sản xuất. Có thể kết nối Cảm biến lực có Tổng trở xuất từ 350 ~ 800 Ohm, nguồn cấp chuẩn 3~15V. Hỗ trợ Cảm biến lực 4 dây, 6 dây.

0 · what size countersink chart

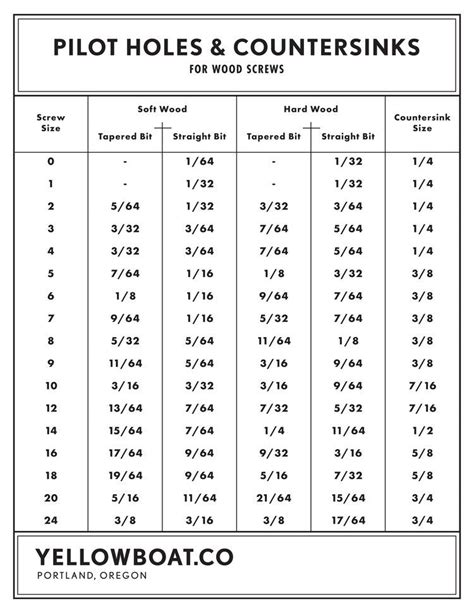

1 · countersinking screws in metal

2 · countersink size for #8 screw

3 · countersink size chart metal

4 · best countersinks for metal

5 · 90 degree countersink chart

6 · 82 vs 100 degree countersink

7 · 100 deg countersink dimension chart

Yamaha controls are available for digital or mechanical rigs and tiller-handle controlled outboards, with some controls handling up to four outboards.

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the .Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the .

Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything .

ford mustang smart junction box

Specify size of screw, type of material and thickness when inquiring. Above is one of our customers countersinking 5/16 holes with UniPunch. Discover UniPunch's countersinking .Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.Create a clean countersink in seconds with forming countersink tools for sheet metal. Eliminate labor-intensive drill and deburr operations.Yes, countersinking can be performed on thin sheet metal, but it requires precise control over depth and angle to prevent deforming the material. Using specialized tools and CNC .

Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner .

what size countersink chart

Designing sheet metal countersinks is easy, with a little thought and guidance from this video.More information on this Tech Tip available at: https://rapidm.Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best . Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything you need to know about designing countersinks, including Approved Sheet Metal’s proprietary formula for .

Specify size of screw, type of material and thickness when inquiring. Above is one of our customers countersinking 5/16 holes with UniPunch. Discover UniPunch's countersinking solutions for efficient metal fabrication. Enhance your .

Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.Create a clean countersink in seconds with forming countersink tools for sheet metal. Eliminate labor-intensive drill and deburr operations.

Yes, countersinking can be performed on thin sheet metal, but it requires precise control over depth and angle to prevent deforming the material. Using specialized tools and CNC machinery helps achieve the necessary precision to maintain the integrity of sheet metal components.

Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner materials will enlarge the inner hole diameter.Designing sheet metal countersinks is easy, with a little thought and guidance from this video.More information on this Tech Tip available at: https://rapidm. Countersinking helps prevent screw heads from protruding out of parts. Here is a step-by-step of how to make a countersink hole in the metal workpiece.

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .

foscam fab28 waterproof junction box

Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything you need to know about designing countersinks, including Approved Sheet Metal’s proprietary formula for .Specify size of screw, type of material and thickness when inquiring. Above is one of our customers countersinking 5/16 holes with UniPunch. Discover UniPunch's countersinking solutions for efficient metal fabrication. Enhance your .Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.Create a clean countersink in seconds with forming countersink tools for sheet metal. Eliminate labor-intensive drill and deburr operations.

Yes, countersinking can be performed on thin sheet metal, but it requires precise control over depth and angle to prevent deforming the material. Using specialized tools and CNC machinery helps achieve the necessary precision to maintain the integrity of sheet metal components.Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner materials will enlarge the inner hole diameter.

countersinking screws in metal

countersink size for #8 screw

Designing sheet metal countersinks is easy, with a little thought and guidance from this video.More information on this Tech Tip available at: https://rapidm.

ford part number 4w4z-15266-aa mount bracket

countersink size chart metal

$179.00

countersink thin sheet metal|100 deg countersink dimension chart