brazing automotive sheet metal Brazing flows the brass rod material over/into usually lapped or fillet joints, but simply melting a steel rod over those same joints will do nothing except make a huge mess. Steel coat hangers get full on fusion welded as the filler material in a similar metal joint. For example, you can have light grey cabinets paired with a darker grey countertop or vice versa. To prevent your grey kitchen from feeling flat or one-dimensional, incorporate different textures. For instance, consider using a .

0 · metal brazing pros and cons

1 · how to braze metal together

2 · how strong is brazing

3 · can you braze galvanized steel

4 · brazing strength vs welding

5 · brazing steel with propane torch

6 · brazing stainless steel with propane

7 · brazing stainless steel sheet metal

What is a truss? A truss in everyday language is a rigid structure that is made up of a collection of straight members. But in an engineering and strength of materials context it has a more specific meaning – in these contexts a truss is a structure made up of members that only carry axial loads.

It is often necessary to braze - solder, or weld next to heat-sensitive materials, a process that requires time-consuming disassembly and reassembly. With this heat-resistant .

Brazing flows the brass rod material over/into usually lapped or fillet joints, but simply melting a steel rod over those same joints will do nothing except make a huge mess. Steel coat hangers get full on fusion welded as the .

I just bought a 3'x4' sheet of metal to cut out and repair my rocker panels on my daily driver. Went over to a buddy's & he was doing the same thing to his truck. He has a 110v 100 amp Lincoln mig but even on the lowest setting was burning thru the metal on his truck and most likely would on my car also. It is often necessary to braze - solder, or weld next to heat-sensitive materials, a process that requires time-consuming disassembly and reassembly. With this heat-resistant paste, you can make. Brazing flows the brass rod material over/into usually lapped or fillet joints, but simply melting a steel rod over those same joints will do nothing except make a huge mess. Steel coat hangers get full on fusion welded as the filler material in a similar metal joint. Learn about MIG brazing, silicon bronze and how to properly set up your welding power source for this process. What is MIG brazing? Brazing processes have traditionally used an oxy-fuel acetylene torch to melt the filler metal, but in MIG brazing, a standard MIG gun is used to run brazing wire.

metal brazing pros and cons

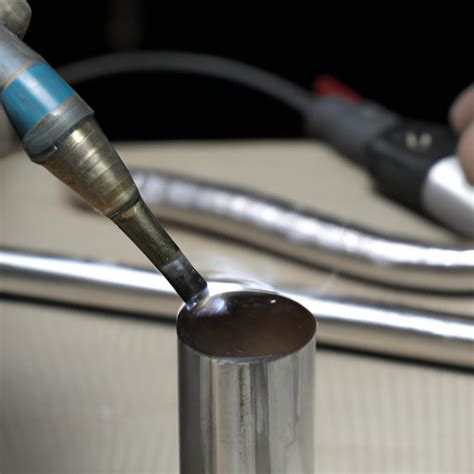

To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare the joint), and appropriate safety gear, such as goggles and gloves.

Suitable for working on motorcycle frames or other automotive sheet metal TIG brazing/welding allows you to work on any metal that will conduct electricity, including more exotic metals such as titanium I picked up a 24 model T that I have found some holes in under old bondo. I have been reading that brazing is bad because of the flux and fillers and paint not wanting to stick to it, I'm wondering what the opion is for tig brazing with silicon bronze rod or is there a better option.

Automotive engineers prefer high-strength steel and aluminum for creating lightweight, fuel-efficient vehicles, and laser brazing successfully joins these dissimilar metals on a unibody vehicle. The silicon bronze rod’s lower melting point makes it ideal for joining together thin sheet metal, galvanized steel, and nuts and bolts, too. It’s nice for sheet metal work because the lower melting temps means less heat, which equals less warping when compared to TIG with, say, an ER70 rod.

how to braze metal together

I'm told brazing pinholes after media blasting is nearly as robust as cutting out the rot, shaping and welding in new sheet metal, but only half as time consuming (as in expensive), but only in areas that don't show.

I just bought a 3'x4' sheet of metal to cut out and repair my rocker panels on my daily driver. Went over to a buddy's & he was doing the same thing to his truck. He has a 110v 100 amp Lincoln mig but even on the lowest setting was burning thru the metal on his truck and most likely would on my car also. It is often necessary to braze - solder, or weld next to heat-sensitive materials, a process that requires time-consuming disassembly and reassembly. With this heat-resistant paste, you can make. Brazing flows the brass rod material over/into usually lapped or fillet joints, but simply melting a steel rod over those same joints will do nothing except make a huge mess. Steel coat hangers get full on fusion welded as the filler material in a similar metal joint. Learn about MIG brazing, silicon bronze and how to properly set up your welding power source for this process. What is MIG brazing? Brazing processes have traditionally used an oxy-fuel acetylene torch to melt the filler metal, but in MIG brazing, a standard MIG gun is used to run brazing wire.

how strong is brazing

To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare the joint), and appropriate safety gear, such as goggles and gloves. Suitable for working on motorcycle frames or other automotive sheet metal TIG brazing/welding allows you to work on any metal that will conduct electricity, including more exotic metals such as titanium

I picked up a 24 model T that I have found some holes in under old bondo. I have been reading that brazing is bad because of the flux and fillers and paint not wanting to stick to it, I'm wondering what the opion is for tig brazing with silicon bronze rod or is there a better option. Automotive engineers prefer high-strength steel and aluminum for creating lightweight, fuel-efficient vehicles, and laser brazing successfully joins these dissimilar metals on a unibody vehicle.

The silicon bronze rod’s lower melting point makes it ideal for joining together thin sheet metal, galvanized steel, and nuts and bolts, too. It’s nice for sheet metal work because the lower melting temps means less heat, which equals less warping when compared to TIG with, say, an ER70 rod.

can you braze galvanized steel

brazing strength vs welding

brazing steel with propane torch

This is not going to save 50% on your electric bill. If it works as described it is simply an input filter. This isn't going to help much because almost all devices have their own internal input filter.

brazing automotive sheet metal|can you braze galvanized steel