how to make sheet metal box with bent edges A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend . $378.99

0 · sheet metal box patterns

1 · sheet metal box layout

2 · sheet metal box design template

3 · sheet metal box and pan tutorial

4 · how to make sheet metal boxes

5 · how to make a metal box

6 · how to cut sheet metal box

7 · how to bend sheet metal box

CNC turning is a subtractive manufacturing process that involves using a CNC lathe to shape a workpiece by rotating it against stationary cutting tools. This precision-focused process can create highly complex cylindrical parts with .

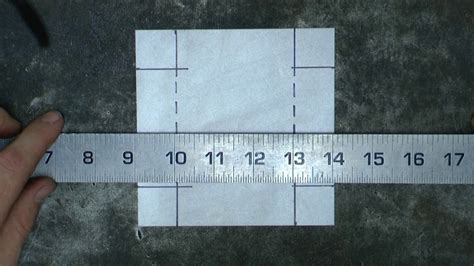

Measure and mark your hem length from one edge of your metal. Scratch a line parallel to the edge you measured from through your marked measurement. Repeat steps one and two for .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend . Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake. .more. Creating a 22 gauge sheetmetal box from scratch. How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. .more.

How to make a sheet metal box with simple tools, no brake press or bender. .more.

After cutting the sheet metal, it is time to form and bend it into the shape of a box. This process involves using specialized machinery, such as press brakes or folding machines, to create precise bends along the edges. The .Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make .

Sheet metal in a flat sheet is not very sturdy. It can be bent, warped, and folded easily; that's why we love it! But when you're designing a sheet metal part, add a few strength-enhancing features to make sure your part lasts for generations.Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a .

sheet metal box patterns

How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal. Sketch Bend and Edge Flange are two very different tools that produce similar results. Why do they exist if they do the same thing? They exist because although the two may give similar results, they are applied at different . Springback is defined as a material's natural tendency to return to its unbent position. This is caused by the tension between the material's expansion on the outside of the radius and the compression on the inside (see .

If you are able to do normal four sided box folds then for the reverse flap you would have the option to make a normal box and then attach a separate plate to one side to create the riser flap. This could be attached with welding, spot .

Maker’s Mob Black Friday//Cyber Monday: https://go.themakersmob.com/black-friday-super-sale-neil/?via=neilSome of you wanted to see how I made the steel boxe.

This is not the real world. It's maths pretending to be real things. You use a plane, extrude an edge and then bevel the corner to get the curve you would expect from a sheet metal bender. Lob a solidify modifier on top and hey presto - Stop thinking about how you would make this from sheet metal, it's an utterly different process. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. Welcome to solid edge tutorial channel - Solid edge Sheet metal bend & unbend - This channel is dealing with everythings about Solid edge Beginners Tutorials. This video was create by BYU-Idaho for the ME 280 Mechanical Design course and demonstrates how an edge flange in the SolidWorks Sheet Metal module can be ed.

On your sheet metal, carefully mark out all the cuts needed using a sharpie and square. Double check measurements. Use a tablesaw or electric shears to accurately cut the metal to size. Clamps can help stabilize the sheet metal while cutting. Bend and Fold the Metal. An electric sheet metal brake is used to bend the metal at sharp 90° angles. SHEET METAL CIRCLE WITH CONTOUR FLANGE The sheet metal bodies can be split up to individual sheet metal components and they can be joined to other components. However, only the moldings on the left and right side of the box can have a joint origin point at the center of the bend radius, because it has a flat side.So I'm doing this as a sheet metal part, so that I can flatten my curved surfaces. Which is fine. I've used sheet metal parts to create corrugated boxes, etc. But I'm stuck here. The top of my pedal car is flat and tapers off in the back. That's all good. The bottom has the same taper but curves up towards the back. All good here too.

Use Boundary patch again to create the outer face of the bend this time with automatic edge chain deselected, and selecting the edges of the surface bodies, rather than anything in a sketch. Set a Tangent Condition on the edges that are 'bent', and leave it as Contact for the 'cut' edges. of the tab. Then added corner seams between the long and sides to set and equal gap, but this pulls the corner style from the sheet metal defaults. With the hem at a width you have a remnant that is present, so in the sheet metal default the remnant has to be modified. I used a min rem of 5 in the bend tab and 4 in the rad for the corners. Hope that helps. #solidedge #solidedgetutorials #siemens #solidedge2023 In sheet metal bending parts we have to give bending views and bending angle of every flange. From thi. Slide your piece of sheet metal into your brake until 1 inch is left sticking out. Clamp it down and pull up on the arm to bend the protruding material up 90 degrees. Repeat this process for the following three sides and you will be left with a pan with 1 inch tall sides. Step 5. Solder or weld the corners on the pan to make it water-tight.

Hems don't like bend regions, and on this part the entire thing is a bend region. If you want a hem on the curved edge, I just tried it with a sketched bend and it works, you just have to sketch out the hem geometry in the profile. That will also allow it to flatten. If you want it on the flat edges, use Edge Flange and set the angle to close .

In this tutorial, you'll learn how to create realistic looking photo quality images in Solid Edge. We will apply materials to parts of the model, add a backg.

Solved: I want to connect two sheet metal faces with a bend. Bend works if two parallel edges are selected. Is there a way to connect two faces with. Autodesk Community > . The bend dailog box lets me select one edge, but not a second edge. Thanks for taking a look. cone.zip. Report. 0 Likes Reply. Message 5 of 6 coreyparks.When developing sheet-metal patterns, ensure you add sufficient material to the base dimensions to make the seams. Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER LAP seam (fig. 2-66). Learn solid edge 2021 how to working with sheet metal tools#solidedge#sheetmetal#tutorialOfficial Software: https://solidedge.siemens.com/en/Music By:Daily B.

Only posts directly related to Fusion are welcome, unless you're comparing features with other similar products, or are looking for advice on which product to buy.Measure and mark your bend lines: Use the measuring tape or ruler to determine the desired length and angle of your bends, then use the scribe or marking tool to create precise lines on both sides of the sheet metal. 4. Support the sheet metal: Ensure that your work surface is clear and stable, then position the sheet metal so that the bend .

I am facing issue of of 2 flange corner and edge overlapping or edge seam in fusion 360 sheet metal. I am currently using Creo 2.0 where we have edge treatment option to control the overlap of the edges and also have option to make corner relief as zero. Will you please tell me how to make such parts in sheet metal of fusion 360 To make a metal box, first decide on the type of metal, and the size of the box you want to create. I recommend using 20 gauge sheet metal for strength and durability. Copper or brass sheet metal are nice choices as they are inexpensive and they antique nicely. Anneal the metal before cutting so that it can be manipulated more easily.This video discusses the different commonly used connection joints found on Sheet Metal Duct work.This series is an introduction to starting to learn Solidworks software by getting to know the Lines in Solidworks. At this stage, We will learn about Sheet .

sheet metal fabricators myrtle beach sc

sheet metal fabricators in littleton

Strong &Durable: With sturdy metal bed frame, the twin box spring ensure stability and long-lasting durability. High Profile Design: The EZBeds twin-box-spring features a 9-inch height, making it perfect for shorter mattresses or for those who prefer a higher bed off the floor.Twin Box Spring, 9 Inch Metal Twin Box Spring Only, Heavy Duty Metal Frame Mattress Foundation Support for 3000lbs, Easy Assembly, Noise Free, Non Slip Options: 4 sizes

how to make sheet metal box with bent edges|how to bend sheet metal box