sheet metal features features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections. Used Sheet Metal Box and Pan Brakes from National, Diacro, and more. Find suppliers near you at the world's leading directory for surplus machinery.

0 · sheet metal layout drawings

1 · sheet metal gusset design guidelines

2 · sheet metal design guidelines pdf

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · design guidelines for sheet metal

6 · characteristics of sheet metal

7 · basics of sheet metal design

$9.99

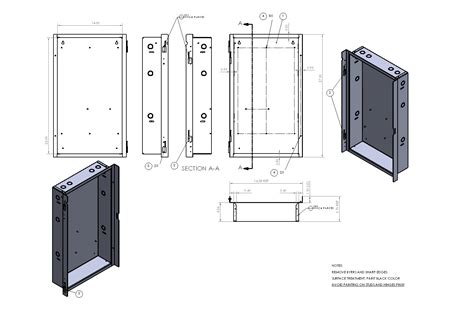

Forming Basics. Laser Cutting. Tolerances. Features. SHEET METAL INTRODUCTION. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, .features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections.Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief . With the release of Inventor 2025, Autodesk has started to move away from feature creation dialog boxes to Properties panel s for Sheet Metal features. As with the standard features in a part modeling environment, the transition will likely take several releases, but I am excited that it has started.

Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief .Introduction to Sheet Metal (14:03) Activity 1: Sheet Metal Features (22:39) Activity 2: Simple Door (24:40)

Flexible Modeling. In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing sheet metal designs.You can mirror selected sheet metal features about a plane at the center of an existing sheet metal part. Sheet metal features you can mirror include: Edge Flange; Miter Flange; Hem; Base Flange/Tab; Closed Corner; The plane used to mirror the sheet metal feature must be centered between the edges of the base flange.Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the . features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections. Virtually As the application of sheet metal continues to expand, the design of sheet metal parts has become a critical aspect of product development. Mechanical engineers must be well-versed in the design of sheet metal components to ensure that the parts meet the necessary functional and aesthetic requirements while keeping the stamping die production .

Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance .

sheet metal layout drawings

Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief .Mirroring the Sheet Metal Bends. When you mirror a sheet metal part, many of the bends are mirrored as well. Creating an Edge Flange. Create an edge flange using the edit sketch profile and offset options. Mirroring a Sheet Metal Feature. You can mirror sheet metal bodies as well as selected sheet metal features.Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance .Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .

You can mirror selected sheet metal features about a plane at the center of an existing sheet metal part. Sheet metal features you can mirror include: Edge Flange; Miter Flange; Hem; Base Flange/Tab; Closed Corner; The plane used to mirror the sheet metal feature must be centered between the edges of the base flange.

Sheet metal features. Analysis Situs provides a generic feature recognition framework that finds various applications. One of them is the recognition and unfolding of sheet metal parts. In this chapter, we cover different aspects of .

Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance .

sheet metal gusset design guidelines

sheet metal design guidelines pdf

sheet metal bending guidelines

Sheet metal forming is commonplace in a variety of industries and everyday items. Read on to find out everything you need to know about sheet metal forming, how it works, and where it’s used. . or validity of the .Sheet Metal Features. This document describes the types of rules that can be applied to models that have advanced feature parameters captured. Driving advanced feature dimensions increases model generation time. Where possible capture feature dimensions (distances, numbers and angles) as dimensions rather than an advanced feature parameter. .

Bend features can join sheet metal faces that do not touch. When you select edges on sheet metal features, you add material to the model using the bend radius and material thickness defined by the sheet metal style. Faces extend in compliance with your default (or selected) bend radius. If the faces are parallel, but not coplanar, you can add a .

You can mirror selected sheet metal features about a plane at the center of an existing sheet metal part. Sheet metal features you can mirror include: Edge Flange; Miter Flange; Hem; Base Flange/Tab; Closed Corner; The plane used to mirror the sheet metal feature must be centered between the edges of the base flange.

Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .Hi u/Jadas922, . You are in "Flat Pattern" mode for sheet metal. Creating sheet metal features is not appropriate in that mode so they are grayed out. Clicking the button in the top right of the viewport will bring you back out of this to the folded state of the model.Three features appear in the FeatureManager design tree that are specific to sheet metal operations. These three features represent a process plan for the sheet metal part: Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance .

The pretraining dataset was used to train the neural network to recognize 12 types of sheet metal machining features and primary planes. As usual, the pretraining dataset was divided into three subsets: training set (containing 49,000 CAD models), validation set (containing 10,500 CAD models) and test set (containing 10,500 CAD models). .You can mirror selected sheet metal features about a plane at the center of an existing sheet metal part. Sheet metal features you can mirror include: Edge Flange; Miter Flange; Hem; Base Flange/Tab; Closed Corner; The plane used to mirror the sheet metal feature must be centered between the edges of the base flange.You can mirror selected sheet metal features about a plane at the center of an existing sheet metal part. Sheet metal features you can mirror include: Edge Flange; Miter Flange; Hem; Base Flange/Tab; Closed Corner; The plane used to mirror the sheet metal feature must be centered between the edges of the base flange.

Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .

commercial sheet metal contractors miami

como funciona el torno cnc

$200.00

sheet metal features|sheet metal design guidelines pdf