copper part cnc machining Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wear This 4 way switch diagram #1 shows the power source starting at the left 3-way switch. This 4 way switch diagram #2 shows the power source starting at the fixture. The white wire of the cable going to the switch is attached to the black line in the fixture box using a wirenut.

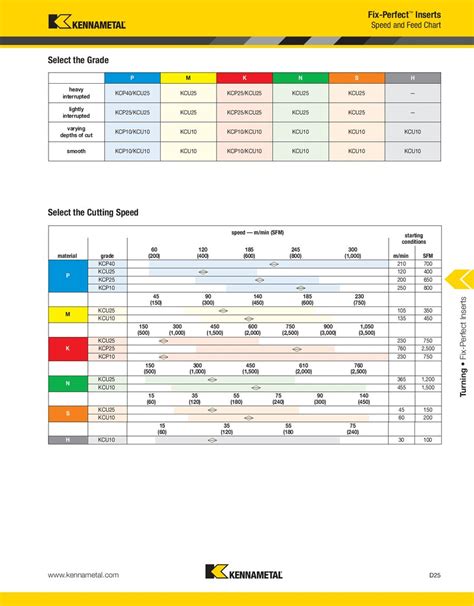

0 · turning copper speeds and feeds

1 · speeds and feeds for copper

2 · machinability of copper 110

3 · end mills for copper

4 · cutting speed for copper milling

5 · copper segregation procedure machine shop

6 · copper segregation policy machine shop

7 · copper machinability chart

Wiring an outdoor circuit is not always difficult. Here are some methods to get power from inside your home to an outside appliance or receptacle not fastened to the house (e.g., pole mounted lantern), or to a detached building (e.g., to a shed, detached garage).

Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it . What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts. Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wearWe offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.

Discover essential tips and techniques for CNC Machining Copper in our comprehensive guide. Learn about copper’s unique material properties and how to effectively machine this versatile metal for optimal results. Generally, most CNC copper parts have good machinability, ductility, and impact strength. They also show a high thermal and electrical conductivity, corrosion, and wear resistance. Another benefit of CNC machining for copper parts encompasses good formability in both hot and cold processes.

You can efficiently machine copper alloys with various methods, including CNC copper milling. This automated process employs computerized controls to manage multi-point rotary cutting tools. As these tools rotate and traverse the workpiece’s surface, they gradually shape it . In this guide, we’ll explore the properties that affect copper’s machinability, the best alloys to use, and effective CNC techniques to achieve optimal results. What is copper CNC machining? The machining process for metal parts is almost the same. Yes, the difference is .Copper CNC machining has many benefits that can improve efficiency and quality in production. First, CNC machining is precise, allowing for complex geometries and detailed designs necessary for automotive components and those used in the aerospace industry.

Let’s look at all the essential details you need for your next CNC machining project, from the different alloys to critical considerations when machining this material. A copper part made with CNC machining.Whether you require custom copper components for electrical, industrial, or specialized applications, our proficiency in turning, milling, and Swiss machining allows us to consistently deliver reliable and precision-crafted solutions to meet your unique needs.

What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts. Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wearWe offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.

Discover essential tips and techniques for CNC Machining Copper in our comprehensive guide. Learn about copper’s unique material properties and how to effectively machine this versatile metal for optimal results. Generally, most CNC copper parts have good machinability, ductility, and impact strength. They also show a high thermal and electrical conductivity, corrosion, and wear resistance. Another benefit of CNC machining for copper parts encompasses good formability in both hot and cold processes.You can efficiently machine copper alloys with various methods, including CNC copper milling. This automated process employs computerized controls to manage multi-point rotary cutting tools. As these tools rotate and traverse the workpiece’s surface, they gradually shape it .

In this guide, we’ll explore the properties that affect copper’s machinability, the best alloys to use, and effective CNC techniques to achieve optimal results. What is copper CNC machining? The machining process for metal parts is almost the same. Yes, the difference is .Copper CNC machining has many benefits that can improve efficiency and quality in production. First, CNC machining is precise, allowing for complex geometries and detailed designs necessary for automotive components and those used in the aerospace industry.Let’s look at all the essential details you need for your next CNC machining project, from the different alloys to critical considerations when machining this material. A copper part made with CNC machining.

turning copper speeds and feeds

sheet metal fabrication in mt.hollyu nj

sheet metal fabrication in navi mumbai

Explore the latest connectivity and structured wiring products from On-Q. Designed for professional installers, On-Q brings homes to life. NEW! Enclosure Inside Accessories. The latest in cable management and device mounting for 3rd party accessories within On-Q enclosures.

copper part cnc machining|end mills for copper