arc welding automotive sheet metal There are a few main types of welding that could be used in automotive repairs. Let’s look at three, but the last will be the most important for you to learn. TIG stands for “Tungsten Inert Gas” welding (Also known as Gas .

If you want to play it safe, achromatic shades like black and white will always highlight a green roof. Warm neutrals like taupe (pictured above on a house designed by Cadence & Co.) are a little softer but equally failsafe. Here are some of the best paint colors for a house with a green roof: Cream; Yellow; Green; White; Red; Gray; Brown .

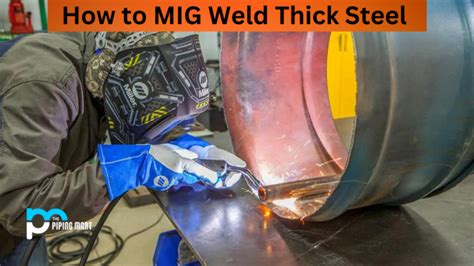

0 · welding thick metal parts

1 · welding sheet metal for cars

2 · welding sheet metal

3 · welding metal for automotive

4 · welding automotive body metal

5 · welding aluminum sheet metal

6 · automotive sheet metal welding

7 · auto body sheet metal welder

If you want to paint your Green roof house, explore this ULTIMATE list of best colors to paint house with a green roof with some cool tips.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Gas-Shielded Arc Welders (GSAW) use electricity to heat a shielding gas. This keeps the torch from melting the side of the metal being welded. This is why gas-shielded welding is also known as shielded metal arc . Automotive sheetmetal and structural welding are vast topics, and it is not possible to give them anything approaching complete coverage here. This article concentrates on some . MIG welding is a common technique in the car welding industry for auto body welds and sheet metal parts. Unlike MIG, TIG is a type of welding that uses a non-consumable .

Automotive Welding: Sheetmetal Guide includes instructional photos, checklists, and step-by-step instructions. Topics covered are basic welding techniques, various forms of sheetmetal work, . There are a few main types of welding that could be used in automotive repairs. Let’s look at three, but the last will be the most important for you to learn. TIG stands for “Tungsten Inert Gas” welding (Also known as Gas .

Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated . Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals. Marty Rice explains the keys to welding on car body panels and how to avoid blowing out the metal. Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. Gas-Shielded Arc Welders (GSAW) use electricity to heat a shielding gas. This keeps the torch from melting the side of the metal being welded. This is why gas-shielded welding is also known as shielded metal arc welding, or SMAW. Automotive sheetmetal and structural welding are vast topics, and it is not possible to give them anything approaching complete coverage here. This article concentrates on some of the fundamentals of welding sheetmetal sections, and on a few ploys that that may make this type of welding easier for you to perform, while producing superior results. MIG welding is a common technique in the car welding industry for auto body welds and sheet metal parts. Unlike MIG, TIG is a type of welding that uses a non-consumable tungsten electrode to produce the weld. A gas shield, usually argon, is used to .

Automotive Welding: Sheetmetal Guide includes instructional photos, checklists, and step-by-step instructions. Topics covered are basic welding techniques, various forms of sheetmetal work, frame repa

welding thick metal parts

welding sheet metal for cars

There are a few main types of welding that could be used in automotive repairs. Let’s look at three, but the last will be the most important for you to learn. TIG stands for “Tungsten Inert Gas” welding (Also known as Gas Tungsten Arc Welding or GTAW). Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals.

Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals.

Marty Rice explains the keys to welding on car body panels and how to avoid blowing out the metal. Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

Gas-Shielded Arc Welders (GSAW) use electricity to heat a shielding gas. This keeps the torch from melting the side of the metal being welded. This is why gas-shielded welding is also known as shielded metal arc welding, or SMAW. Automotive sheetmetal and structural welding are vast topics, and it is not possible to give them anything approaching complete coverage here. This article concentrates on some of the fundamentals of welding sheetmetal sections, and on a few ploys that that may make this type of welding easier for you to perform, while producing superior results. MIG welding is a common technique in the car welding industry for auto body welds and sheet metal parts. Unlike MIG, TIG is a type of welding that uses a non-consumable tungsten electrode to produce the weld. A gas shield, usually argon, is used to .

Automotive Welding: Sheetmetal Guide includes instructional photos, checklists, and step-by-step instructions. Topics covered are basic welding techniques, various forms of sheetmetal work, frame repa There are a few main types of welding that could be used in automotive repairs. Let’s look at three, but the last will be the most important for you to learn. TIG stands for “Tungsten Inert Gas” welding (Also known as Gas Tungsten Arc Welding or GTAW). Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals.

Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals.

welding sheet metal

steel guitar forum/band in a box/learning from franklin

Where I can really smell it is either by smelling the exhaust pipe from the outside of the house when the unit is not running OR if I open up the furnace cover and smell around the burner chamber. I'm 99% confident though that this smell is not gas.

arc welding automotive sheet metal|welding thick metal parts