grain flow direction in sheet metal The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions and . See more However, when discussing modern house keys, they are typically made of brass, which is an alloy of copper and zinc, or a combination of nickel and silver. Although they can be plated in a variety of colors, most keys are typically silver or brown in color.

0 · rolling direction of steel plate

1 · rolling direction of sheet metal

2 · metal grain direction diagram

3 · metal grain direction chart

4 · how to fold metal sheet

5 · how to bend galvanized steel

6 · grain size vs strength

7 · diy sheet metal bending

CNC format files are digital instructions that tell a CNC machine how to create a specific part or product. These files contain detailed information about toolpaths, speeds, feeds, and other parameters necessary for machining operations. G-code is .

Like most inorganic solid materials, the kind of metals used in manufacturing is in a polycrystalline state: they are solid and consist of very small crystals or crystallites of various sizes and orientations held together by thin layers of amorphous solid. These crystals — . See more

The grain size of sheet metal can vary for different reasons. If it is heated for too long a time, for example, diffusion can take place across grain . See more

rolling direction of steel plate

rolling direction of sheet metal

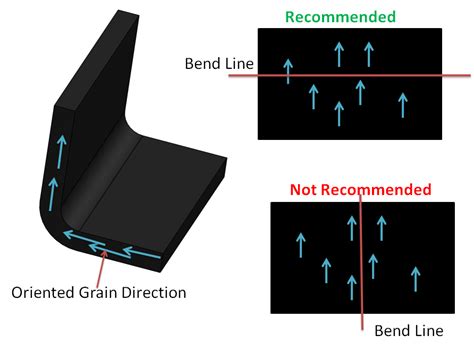

The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions and . See more LT-Long Transverse: perpendicular to direction of principal metal extension. In products whose grain structure clearly shows directionality (width-to-thickness ratio greater than two) it is that perpendicular direction parallel to the . Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. FIGURE 1. Bends . Figure 3 Look at the surface of sheet metal through a microscope or a magnifying glass, and you should see the grain direction. Movement takes place along the cleavage .

grain orientation effects have on critical strain localization. The approach adopted for this research integrates Rt-based localiza-tion maps with grain orientation analysis and it is expected that . In this article, we’ll highlight grain structure and how grains form in metal, how forging affects grain structure, and why grain flow in components is important. Last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and orientation. This month we’ll dive into how exactly those grains affect how a . Each grain has its own unique orientation, and the areas between grains are known as grain boundaries. How Grains Form in Metal. When a metal material solidifies from a .

Plate bending can be split into two main categories, plate rolling and press braking. The latter consists of much tighter radii, therefore the risk of fracture is much greater and the need to bend perpendicular to the grain .Like a game of Jenga, aligning grain size and direction helps ensure everything fits together without a hitch. With this article, we'll explore causes of misalignment, troubleshooting tips for . Here’s a DFM tip: When specifying a grain direction, perpendicular to the bend is structurally the best practice. . Here is another DFM tip: Use Gauge Tables in your 3-D sheet metal work flow. An accurate Gauge Table .

This has to do with the sheet grain direction. Where Does Grain Direction Come From? The grain direction is in the rolling direction of the sheet as it was being manufactured. Two rollers compressing the hot metal cause the . Yes, you can get a Grain direction note added to your drawings in SOLIDWORKS. Your part needs to have a Sheet Metal feature and Flat Pattern feature. Edit the Flat Pattern feature to set the Grain dirction/coil direction first. Then on the drawing, insert a Bend Table and the Grain direction note as well as the Fixed Face note will appear. The Effect Of Grain Direction In Sheet Metal Bending.For Press tool Design and Other course visit : https://industrylearning.co.in/courses/press-tool-design-nx/

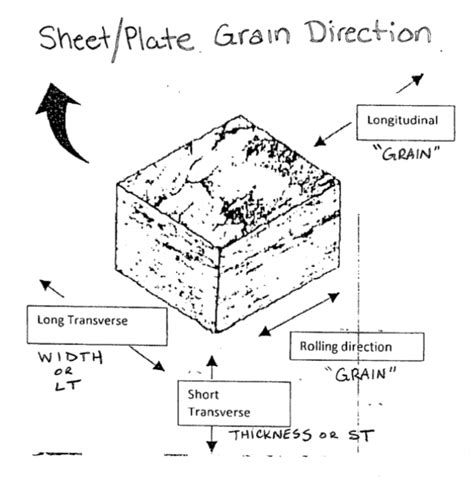

Hi Friends,In this video you will learn Introduction to sheet metal process | Grain direction | Bend allowance & K-factor | Spring backCheck out other videos. In stainless steel, it can be tough and sometimes impossible to define the grain and grain direction. Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. Read more: Grain direction’s effect on sheet metal bendingThe grain direction runs parallel to the rolling direction. For sheet or Panel stock the different directions through the raw material are defined as follows: Figure 4.2.2‑7: Definition of Panel Stock Grain Dire . So, from time to time we need to show the direction of the grain on sheet metal parts. In order to do this I've been clicking on the view, creating a new sketch, then I've been drawing little dotted lines on a mostly blank area, constraining them(in case the part changes so they will stay attached) then I back out of the sketch, using a dimension style I set up for .

metal grain direction diagram

The mean grain size which is set by the tessellation was kept constant, i.e. 100 μ m. Table 1 also gives the number of the grains in the thickness direction, showing that in the case of a sheet thickness of 100 μ m there is only one grain over the thickness When you make anything out of sheet metal, cabinets, enclosures, chassis, housings. you need to think about the grain structure. Talk to GP PRECISION.https.In metallurgy, the grain flow refers to the plastic deformation of crystallites during rolling or forging. During forging, the brittle impurities of the metal are broken and distributed in a granular or chain shape along the main elongation direction of the metal, while the plastic impurities are distributed in a band along the main elongation direction with the metal deformation, so that the . However, grain flow direction on the metal sheet is often neglected by the researchers. In the present paper, an attempt has been made to take the grain flow direction into account while designing the computer algorithm. Different algorithms for computer aided nesting have been reported by several researchers. Adamowicz and Albano [1] proposed .

Control of grain flow is one of the major advantages of shaping metal parts by rolling, forging, or extrusion. . Proper placement of the parting line ensures that the principal grain flow direction within the forging will be parallel to the principal direction of service loading. . Sheet Metal Forming Fundamentals. Ferritic Stainless Steels .a) cold working provides better accuracy b) hot working provides poorer surface finish c) cold working provides for increased strength due to work hardening d) cold working is only done at temperatures below 100 degrees C e) cold working yields possible direction properties due .

What Is Grain Flow? Grain flow refers to the directional orientation of the grains in metal during deformation. How Grain Flow Affects a Metal’s Mechanical Properties . Grain flow directly affects the material’s mechanical properties since it determines the direction that the underlying grains push or pull when under stress or fatigue.

Study with Quizlet and memorize flashcards containing terms like Layout & Forming Purpose, Grain, grain determined and more. . the direction of lay of a piece of sheet metal. grain determined. determined by the manufacturing process. Grain rule. all bends must be made so they are not parallel with the grain. Welded tubing can be made from sheet curled in either direction, which means grain orientation can be circumferential or axial (longitudinal). . The impurities outline the grain flow; the metal grains themselves may be too small or not clearly visible macroscopically, esp in ferrous alloys. In weldments (castings), grains are usually more . Hi guys, if i am buying from discount steel, lets say some a36 -1/4"thick and 1.125" wide in 8 foot lenghts. I want to make some serious shelf brackets for the workshop. How do i tell the direction of grain. So i cut 14" and bend slowly, hoping i am going against the grain. Do i . Figure 1 A material’s grain direction adds yet another variable to a bending process. . Sheet metal with an average yield strength of 41,000 PSI can be sold as A36 steel, even though it is 13 percent harder than 36,000-PSI steel. . This occurs because the power flow of a press brake is typically produced at the ends of the bed while we .

Grain Direction and the Bend Line. The sheet or plate material is the weak link in forming. . but on a limited basis. Flow stress, or the stress required to sustain plastic deformation at a given level of strain, also comes into play. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of the . The material investigation in this study was a commercial DC04 metal sheet (produced by Baosteel), which was widely used in automobile panels due to its excellent performance in stamping and drawing. The thickness of the DC04 sheet was 1 mm, with an average grain size of 20 µm. The chemical compositions of DC04 are listed in Table 1.Forging is as much a skill as it is an art. For more than 6,000 years, forging techniques have evolved with one key goal in mind: to advance what forged components can do. Let’s explore why grain flow is an important part of the forging process and how CanForge utilizes this to ensure reliable and superior quality in our forged products.

Explore our complete guide to overcoming springback in sheet metal forming and ensure flawless, precise fabrication results. . Orientate the material correctly: Aligning material grain flow with the direction of the forming forces can help control spring back.

metal grain direction chart

Introduction to Mechanical Properties. Tensile property characterization of mild and High Strength Low Alloy steel (HSLA) traditionally was tested only in the rolling direction and included only yield strength, tensile strength, and total elongation.Properties vary as a function of orientation relative to the rolling (grain) direction, so testing in the longitudinal (0°), transverse (90 .Have you encountered challenges with Grain Direction in sheet metal? Do you just want to know what that’s all about and how you can make the entire process .The 4.1-mm-thick 6061-O aluminum sheet metal was used in this study. Aluminum 6061 is a type of Al–Mg–Si alloy in which the grain flow can be easily etched. . and Z V were considerably different from those in other situations because it was not just bending in a single direction. The grain flow exhibited good symmetry in areas X V and Z V . SOLIDWORKS Flow ; SOLIDWORKS Plastics ; Abaqus Unified FEA . prior to SOLIDWORKS 2011 we were unable to specify a Grain Direction in a sheet metal part so the Fixed Face viewed Normal To was the direction for your Flat Pattern. With SOLIDWORKS 2011 SOLIDWORKS added a series of new properties for Sheet Metal parts that a lot of information .

how to fold metal sheet

how to bend galvanized steel

grain size vs strength

Discover 35 creative, smart and practical repurposing ideas for your cardboard boxes. Follow our projects and get creative today.

grain flow direction in sheet metal|metal grain direction chart