how to make a sheet metal cone pattern Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago. .more. Metal fabrication—the process of transforming raw metal materials into finished products—is a cornerstone in the world of manufacturing. This intricate craft combines skill, technology, and invention and plays a key role in shaping the infrastructure of .What is Metal Fabrication? Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed .

0 · truncated cone from flat sheet

1 · sheet metal transition layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone formula

4 · sheet metal cone fabrication

5 · creating a cone layout

6 · cone sheet metal calculator

7 · cone layout formula

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

truncated cone from flat sheet

cnc machine for home workshop

sheet metal transition layout

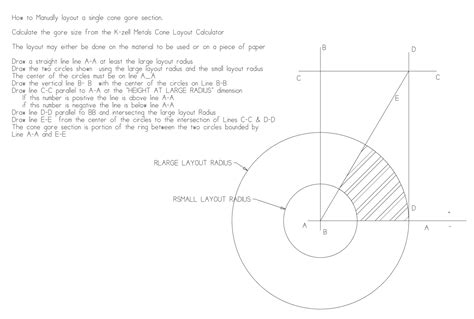

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular. Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

How To Build A Steep Cone in Sheet Metal. Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted. Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago. .more.Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with .

Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I'm here to alleviate your worries and provide you with the correct workflow. Developing a pattern for a cone with a pitch using radial line development. What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view .

cnc machine for sheet metal fabrication

Right Cone. Draw an elevation view. Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts). Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. . Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material.You can find cone calculators online,.For very large cones (base or height over 600), or when Full Scale is un-checked (diagram is not Full Scale), check Dimensions to show correct measurements to mark out cone. See Volume Calibration Templates to mark incremental fluid volumes on cone. Learn how to layout a cone in sheet metal Learn how to layout a cone and the formula, these numbers can be replaced with your dimensions. The formula for the cone is.

The patern of the cones are a half circle cut out of a 13" wide strip of sheet metal. So the question is - is there a source of a simple machine that I have missed, or even possibly a trick of the trade that I am unfamilliar with.Step 1: Select Full Cone Option from Application Home Screen as shown in the below image for step 1. Step 2: Enter Input data of Cone Diameter as 500 mm and Cone Height as 750 mm in the input Fields and Press Calculate Button as shown in the below image of step 2. With sheet metal parts there's a "Flat Pattern" feature that's created automatically but it greatly depends upon how the part was created. The "Flat Pattern" is the bottom feature in the model tree and it's suppressed. . Last night I wanted to create a sheet metal cone that had a 16" OD on one end, a 12" OD on the other. Most attempts ended .

But I can't figure out how to make a cone in Sheet Metal. (I can make cones all day in Model, but they won't flatten/unwrap) I've actually managed to successfully accomplish all this with a cylindrical shape, having created the shape with the flange tool. . When I go to "create flat pattern", no part of my model is selectable as the .

This video is by Christopher Nelson at GoEngineer. To learn more about SOLIDWORKS and part modeling, visit our website at https://store.goengineer.com/colle.

Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt.

Creating a cone in sheet metal, which can be flattened for a pattern, is something you'll need to know a trick or two to do. . Fusion 360's math as. Creating a cone in sheet metal, which can .

Check out this channel (MECHBUZZ) - https://www.youtube.com/channel/UCg2nh83oJkc5nrvwIaV2aVQDownload 2d drawing here - https://drive.google.com/file/d/1Lb076. Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt. For creating a cone from sheet metal or any flat material. Added the function of saving the development of a straight and truncated cone to a DXF file. Export the flat pattern as a dxf file, then you can open it with any CAD program like Acad.For very large cones (base or height over 600), or when Full Scale is un-checked (diagram is not Full Scale), check Dimensions to show correct measurements to mark out cone. See Volume Calibration Templates to mark incremental fluid volumes on cone.

I'm hoping onshape will automatically convert your words "how can I make" to "we should be able to make" so that this gets properly absorbed as an improvement request. I was surprised that sheet metal cones are not possible out of the .

Learn Autodesk Inventor sheet metal tutorial how to create cone object, check it out!!!Don't forget guys, if you like our videos please "Subscribe", "Like", . Learn how to convert a solid cone into sheet metal, and pattern a cut feature along a curve driven pattern at the flat pattern level.For more information abo. Sheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this blog post, the experts at Avon Lake Sheet Metal will guide you through the steps we take when fabricating a cone with sheet metal for .

How to use the Sheet Metal Features in Autodesk Fusion 360 (for Complete Beginners) Learn how to create sheet metal cone.TEACHING THE NEXT GENERATIONTUTORIAL. This Video Demonstrates the Cone Flat-Pattern Capabilities of Solidworks Sheet Metal By KRISHANTHA PRADEEP

There are many different ways to lay out this pattern. This is just one way and I find that is the easiest and quickest way. Enjoy

I want to make a Chinese hat type cone from some flashing metal. The key dimension is the bottom diameter of the hat, which we will say is 8" (25 " circumference). I used to know how to lay it out with the correct "pie slice" to have the plane figure make the appropriate cone when the edges are joined together.

Step 8: Benefits of Fabricating a Cone From Sheet Metal. There are several benefits to fabricating a cone from sheet metal, including: Sheet metal is durable and can withstand harsh environments. Sheet metal cones can be made to exact dimensions, ensuring a perfect fit for any application. Sheet metal cones are lightweight and easy to transport.

SHEET METAL CIRCLE WITH CONTOUR FLANGEUsing the Flat Pattern Cone Calculator App makes it quick and easy to draw any cone in minutes.In this video I will draw a Concentric Reducer Cone. Flat patt.20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.

Here a video how to make an Eccentric Reducer

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

how to make a sheet metal cone pattern|creating a cone layout