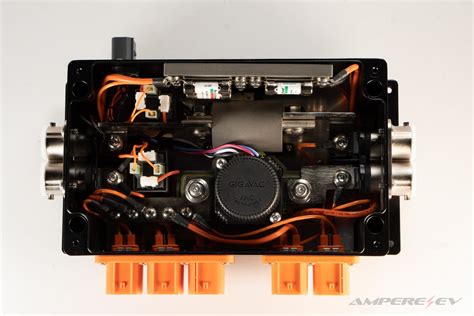

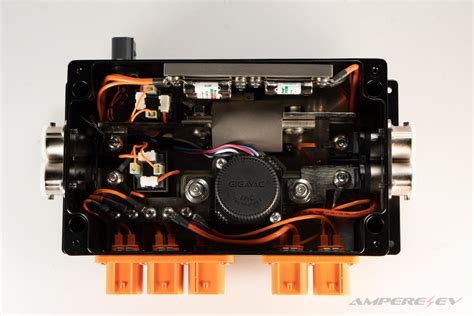

battery junction box definition Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack. Pair light blue with upper cabinets in white to harness natural light and add volume to a smaller kitchen. A gray patterned backsplash offers a touch of playfulness and ties into the.

0 · physical location of battery junction

1 · junction box in electrical vehicle

2 · high voltage junction box automotive

3 · high voltage battery junction box

4 · high current battery junction box

5 · battery terminal junction block

6 · battery junction box ford f350

7 · 2022 f350 battery junction box

The metal bank is a dedicated bank where players can store all core ores and bars. It can be accessed via any anvil, forge, furnace, Burial Anvil, Burial Forge, ore box, or through the regular bank interface (though you cannot deposit or withdraw from regular banks).

Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.This presentation will discuss the different trends and topologies for battery .The Battery Junction Box (BJB) is a switching unit for the battery in an electric vehicle. It connects or disconnects the components in the vehicle, which need energy from the battery. With one or more bus interfaces, this component is .The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the .

Figure 1 presents a typical battery management system architecture containing a battery management unit (BMU), a cell supervisor unit (CMU), and a battery junction box (BJB). A BMU typically has a . A traditional battery junction box is a relay box or switch box with a power contactor that connects the entire battery pack to a load inverter, motor, or battery charger. Figure 1a shows a traditional BMS.The Battery Junction Box (BJB) is the pack-level sensing part of the BMS. The BJB measures high voltages. This measurement allows monitoring connections of the contactors to the . Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and .

Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.The Battery Junction Box (BJB) is a switching unit for the battery in an electric vehicle. It connects or disconnects the components in the vehicle, which need energy from the battery. With one or more bus interfaces, this component is networked with the entire vehicle.The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.

Figure 1 presents a typical battery management system architecture containing a battery management unit (BMU), a cell supervisor unit (CMU), and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of . A traditional battery junction box is a relay box or switch box with a power contactor that connects the entire battery pack to a load inverter, motor, or battery charger. Figure 1a shows a traditional BMS.The Battery Junction Box (BJB) is the pack-level sensing part of the BMS. The BJB measures high voltages. This measurement allows monitoring connections of the contactors to the inverter and the charger. The BJB also precisely measures the system’s current, and monitors the battery to chassis isolation.

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. This presentation will discuss the different trends and topologies for battery-junction-box or battery-disconnect units in electric vehicles. We will describe the challenges and solutions to measure different parameters such as voltage, current, temperature and insulation resistance, using integrated analog front ends.How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and electrical impedance spectroscopy calculations that will result in optimal utilization of the EV battery.Battery junction boxes provide battery power at 200.1000VDC to components like inverters or DC-chargers, which may draw currents in the range of 500A or more. To simulate such a scenario without the need of an electronic load of several 100kW, standard power supplies can be used.

physical location of battery junction

Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.The Battery Junction Box (BJB) is a switching unit for the battery in an electric vehicle. It connects or disconnects the components in the vehicle, which need energy from the battery. With one or more bus interfaces, this component is networked with the entire vehicle.The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring. Figure 1 presents a typical battery management system architecture containing a battery management unit (BMU), a cell supervisor unit (CMU), and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of .

A traditional battery junction box is a relay box or switch box with a power contactor that connects the entire battery pack to a load inverter, motor, or battery charger. Figure 1a shows a traditional BMS.

The Battery Junction Box (BJB) is the pack-level sensing part of the BMS. The BJB measures high voltages. This measurement allows monitoring connections of the contactors to the inverter and the charger. The BJB also precisely measures the system’s current, and monitors the battery to chassis isolation.

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. This presentation will discuss the different trends and topologies for battery-junction-box or battery-disconnect units in electric vehicles. We will describe the challenges and solutions to measure different parameters such as voltage, current, temperature and insulation resistance, using integrated analog front ends.

How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and electrical impedance spectroscopy calculations that will result in optimal utilization of the EV battery.

metal boxes china

junction box in electrical vehicle

What happens when water gets inside an electrical outlet? When water gets inside an electrical outlet, there’s a danger, end of story! Not only will the outlet stop working but there’s also a high risk of electrical shock, burns, and short circuits.

battery junction box definition|high voltage junction box automotive