types of metal fabrication process Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, . Position the pieces to form the desired corner shape: edge to edge (open), flush (closed). Deposit your weld bead along the intersection, filling the gap to create a fillet weld. Maintain proper heat control and travel speed to achieve full penetration and .

0 · what are fabricated metal products

1 · types of metalworking

2 · types of metal processing

3 · products made by fabrication

4 · manufacturing methods for metals

5 · manufacture of fabricated metal products

6 · different methods of fabrication

7 · basic metal fabrication

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

Have you ever stopped to ponder how metal is shaped, formed, and treated? That broad definition can be summed in three words: metal fabrication processes.

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .In this list, you’ve encountered popular types of metal fabrication like casting, forging, metal stamping, cutting, extrusion, and welding. As mentioned before, these methods are used for .Cutting. Laser cutting: A technique that uses high-intensity light beams to cut metal via burning, melting or vaporizing. Saw cutting: A highly precise cutting method requiring skilled workers and specialized saw blades. Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .

Fabrication of metal has three main phases, design, fabrication, and installation. This process adds value to raw metal, transforming it into usable products and components. . Different projects require different approaches. Here are some of the most common methods used in the steel fabrication process: Cutting is the preliminary and pivotal .

This comprehensive guide will explore various types of metal fabrication, including the use of press brakes, stainless steel, and other manufacturing processes to transform raw materials into functional and . There are various types of fabrication processes or techniques applied in modern production, choose the right metal fabrication method based on the material, tolerances, .

Introduction to Metal FabricationMetal fabrication is all about shaping and assembling metal parts into final products. Think of it as playing with building blocks, but instead of plastic, we're dealing with metal. There are many ways to do this, and each method offers its own advantages depending on what you're trying to build. At its core, fabrication involves .

Metal fabrication is a process that is a big part of a lot of products and appliances that regular people use in their day-to-day life. This article attempts to present some basic information about metal fabrication, its different types, methods and so on. Types of Metal Fabrication Processes. The journey from sheet metal to metal products starts with CAD engineering. After making the models, each part goes through the necessary sheet metal fabrication processes. The . Here is more on the different types of metal fabrication processes. According to Thomas Net: “Metal fabrication is a broad term referring to any process that cuts, shapes, or molds metal material into a final product. Instead of an end product being assembled from ready-made components, fabrication creates an end product from raw or semi .

The different types of metal fabrication processes are applied onto a metal raw material in order to produce metal products for a variety of uses. While some of these processes employ the use of a constant application of electrical, or heat energy, some processes simply require physical manipulation in different levels, or degrees. . Here are the main steps involved in the Structural Steel Fabrication Process: Design Creation. In this step, the experts look at the design requirements and then create a structural steel design that will fit your project. . This is the most common structural steel fabrication type that finds numerous applications across many disciplines . Adaptive technology enhances the flexibility of steel fabrication processes. Advanced software and machinery can adjust to different types of steel and fabrication needs in real time. This adaptability allows for more efficient handling of various materials and complex designs. Quality Control in the Steel Fabrication Industry In industrial fabrication processes, chances are one or more of the following methods will be used to finish or produce a part or end product: Common Methods or Types of Fabrication Cutting. The cutting of a metal workpiece is a common fabrication technique in which the material is split or cut into smaller sections. Cutting can be used as a .

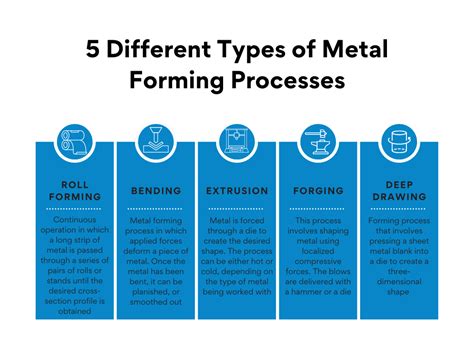

An Overview of the Types of Metal Fabrication. Metal fabrication is a broad term for several types of fabrication processes. These methods include cutting, punching, forming, shearing, and welding. In each case, the metal is shaped, cut, or molded into the desired finished product. Manufacturers employ these processes individually or in .What are the types of metal forming processes? Bending; Stretching; Deep Drawing; Roll Forming; Extrusion; Punching; Stamping; Ironing; Hydroforming; Metal forming is a part of the metal fabrication process and is used to create structural parts or complex pieces out of metal sheets and tubing. It’s an essential procedure for a wide variety of products — without it, our .Good sheet metal design goes beyond basic guidelines and considers the type of sheet metal fabrication process, material, finish, fastening, and tailors all these factors to the specific function. Here are some useful resources on sheet metal fabrication, as well as other resources related manufacturing if you want to delve deeper. Sheet Metal Fabrication: Different Types of Fabrication. Sheet Metal Fabrication is a versatile process that involves forming and shaping metal sheets into a wide array of components or structures. This method is extensively employed across manufacturing industries, particularly in the production of enclosures, panels, casings, and other .

The metal fabrication process can seem complicated. Here is an explanation of the different types of processes. According to Genevieve Mills: “Metal fabrication is a broad term referring to any process that cuts, shapes, or molds metal material into a final product. Material Type: The choice of metal – whether it’s stainless steel, aluminum, or brass – significantly influences the fabrication process. Each metal has unique properties like strength, malleability, and corrosion resistance, dictating its suitability for different applications.

Types of Heavy Metal Fabrication . Sheet metal fabrication, as the name suggests, focuses on working with thin sheets of metal. This process is essential for creating various products, from household appliances to automobile parts. . What Is the Metal Fabrication Process? Types of Metal Fabrication The Sequence of Steps in Metal Fabrication Tips to Optimize Your Design Metal Fabrication Project Choose Superior Manufacturing as Your Precision Metal .Introduction to the three 3 types of metal fabrication Metal fabrication is the backbone of many industries, from the cars we drive to the buildings we live and work in. At its core, metal fabrication is the process of creating metal . One of the oldest forms of metal fabrication processes in existence, forging is still widely used by blacksmiths and fabricators for detailed and artistic work to this day. . Like forging, casting is also one of the oldest types of metal fabrication and can be applied to a variety of metals including steel, iron, gold, copper, silver, and .

Metal casting is one of the oldest metal fabrication processes. Metal is heated to its melting point to convert it to liquid form. This molten metal is then poured into a die (which is also a fabricated metal product), which has a cavity of a specific shape inside it. The molten metal then solidifies inside the die into the cavity’s form.

what are fabricated metal products

There are many things that can be done to metals, so there are many different types of metal fabrication processes. Some of the common metal fabrication processes include: Cutting and Notching: Cutting is one of the simplest metal fabrication processes. It involves dividing a piece of metal into smaller pieces of the required length. However, each metal fabrication process may be used to cut, drill, fold and weld the strongest material on earth: . One of the oldest types of metal fabrication involves casting, where molten metal is poured into a mold and is left to solidify into a specific form. As one of the most flexible methods of metal fabrication, casting is ideal for .

Metal fabrication is the procedure of constructing machines and systems from raw metallic materials. The procedure consists of cutting, burning, welding, machining, forming, and assembly to create. There are several types of metal fabrication processes, each suited to different materials and applications. Some common processes include: Sheet Metal Fabrication: Involves shaping metal sheets into various forms using cutting, bending, and joining techniques. Sheet metal fabrication is widely used in the automotive, aerospace, and .A set of six-axis welding robots.. Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added [1] process involving the creation of machines, parts, and structures from various raw materials.. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product.

Metals are manipulated to create components we rely on every day. Different processes transform billets and sheets of metal into their desired shapes. Our cars, laptops, cell phones, and kitchen appliances exist because of the metal fabrication process. Metal fabrication encompasses every step needed to create a final component part or product.

Types of Metal Fabrication Processes. The phrase “metal fabrication” is used to describe a wide variety of techniques used to transform raw metal into a usable form. Fabrication is the process of making anything from raw or semi-finished materials, as opposed to assembly, which involves putting together pre-made parts. .Common in construction and industrial fabrication, stick welding handles many types of metals well. Slag forms on top of the welded metal and must be removed after welding. This waste ensures the weld remains clean and durable. Stick welding is reliable for heavy-duty projects and diverse applications. Next, explore flux-cored arc welding.

electrical box 9355

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

types of metal fabrication process|basic metal fabrication