electrical outlet box for fire rated wall These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the .

The Best CNC Routers for Woodworking. 1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph Fab: Most Versatile Wood CNC Machine

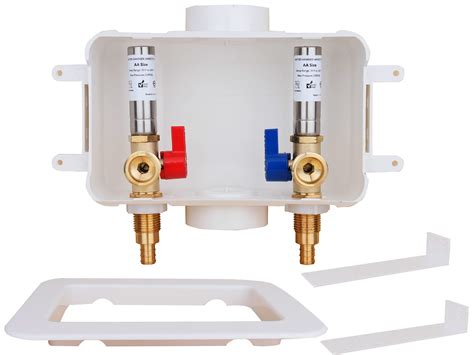

0 · washing machine recessed wall box

1 · recessed plumbing wall box

2 · receptacle in fire rated wall

3 · oatey fire rated washer box

4 · fire rated electrical outlet box

5 · fire rated electrical junction boxes

6 · allied moulded fire rated boxes

7 · 2 hour fire rated box

$49.98

with fire rating not exceeding 2 hours. These metallic boxes are not required to be marked specifically as suitable for use in fire-resistant rated . See more

Unlike metallic boxes, all nonmetallic outlet and switch boxes intended for use in fire-resistant rated assemblies must be specifically investigated for use in such assemblies, and are . See more

The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that .

The IBC lists the specific requirements for electrical outlet boxes (membrane penetrations), explaining what protection is needed to maintain the rating of the wall assembly. This document will focus on the requirements of Section . All boxes must also have more than 24 inches of horizontal spacing between outlets on either side of the fire rated wall. This means that on 24" OC studs, outlets must be placed at least one stud cavity away (both sides .These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the . Some of these products allow as little as three (3) inches of separation for outlets on opposite sides of a wall. Nonmetallic outlet boxes evaluated for installation in fire resistive .

Allied Moulded’s fiberglass reinforced polyester (FRP) electrical boxes give you the freedom to make the most of your space, with an exclusive industry fire rating, backed by UL® testing, that bucks the installation limitations found in 2-HR fire .Q: What are the requirements for maintaining the fire integrity of a fire-resistive wall when installing electrical boxes? A: According short answer is that it depends on not only the size of the individual box, but also the aggregate size of .

Fire-rated outlet box spacing. The electrical inspector says that I cannot install receptacles in fire-rated walls closer than 24 inches back-to-back. This is an apartment building with rooms on .Electrical boxes of any size or type installed as protected using opening protective materials. 4. Listed electrical boxes of any material, installed in accordance with listing. 8. Ceiling .UL evaluates both metallic and nonmetallic outlet and switch boxes for use in fire-resistant rated assemblies, and provides guidance for proper installation in the associated product category guide information pages.

The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that do exceed 16 sq. in., 3) Non-metallic electrical boxes of any size, and 4) Boxes other than electrical boxes Cover plate gaskets Box inserts .The IBC lists the specific requirements for electrical outlet boxes (membrane penetrations), explaining what protection is needed to maintain the rating of the wall assembly. This document will focus on the requirements of Section 713.3.2 of . All boxes must also have more than 24 inches of horizontal spacing between outlets on either side of the fire rated wall. This means that on 24" OC studs, outlets must be placed at least one stud cavity away (both sides of wall).These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the studs.

384 single gang metal box

Some of these products allow as little as three (3) inches of separation for outlets on opposite sides of a wall. Nonmetallic outlet boxes evaluated for installation in fire resistive assemblies are provided with the appropriate Listing Mark .Allied Moulded’s fiberglass reinforced polyester (FRP) electrical boxes give you the freedom to make the most of your space, with an exclusive industry fire rating, backed by UL® testing, that bucks the installation limitations found in 2-HR fire resistive walls.

Q: What are the requirements for maintaining the fire integrity of a fire-resistive wall when installing electrical boxes? A: According short answer is that it depends on not only the size of the individual box, but also the aggregate size of multiple outlet boxes in a given size wall.

Fire-rated outlet box spacing. The electrical inspector says that I cannot install receptacles in fire-rated walls closer than 24 inches back-to-back. This is an apartment building with rooms on each side of the firewalls, and the spacing of receptacles is critical. Can you help?

3d model to cnc machine

Electrical boxes of any size or type installed as protected using opening protective materials. 4. Listed electrical boxes of any material, installed in accordance with listing. 8. Ceiling membrane penetrations by listed luminaires or luminaires protected with listed materials tested for fire-resistance. Questions??UL evaluates both metallic and nonmetallic outlet and switch boxes for use in fire-resistant rated assemblies, and provides guidance for proper installation in the associated product category guide information pages.The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that do exceed 16 sq. in., 3) Non-metallic electrical boxes of any size, and 4) Boxes other than electrical boxes Cover plate gaskets Box inserts .The IBC lists the specific requirements for electrical outlet boxes (membrane penetrations), explaining what protection is needed to maintain the rating of the wall assembly. This document will focus on the requirements of Section 713.3.2 of .

All boxes must also have more than 24 inches of horizontal spacing between outlets on either side of the fire rated wall. This means that on 24" OC studs, outlets must be placed at least one stud cavity away (both sides of wall).These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the studs. Some of these products allow as little as three (3) inches of separation for outlets on opposite sides of a wall. Nonmetallic outlet boxes evaluated for installation in fire resistive assemblies are provided with the appropriate Listing Mark .Allied Moulded’s fiberglass reinforced polyester (FRP) electrical boxes give you the freedom to make the most of your space, with an exclusive industry fire rating, backed by UL® testing, that bucks the installation limitations found in 2-HR fire resistive walls.

washing machine recessed wall box

Q: What are the requirements for maintaining the fire integrity of a fire-resistive wall when installing electrical boxes? A: According short answer is that it depends on not only the size of the individual box, but also the aggregate size of multiple outlet boxes in a given size wall.Fire-rated outlet box spacing. The electrical inspector says that I cannot install receptacles in fire-rated walls closer than 24 inches back-to-back. This is an apartment building with rooms on each side of the firewalls, and the spacing of receptacles is critical. Can you help?

recessed plumbing wall box

3d printing and cnc machining industry trends

In the 14th century, an instrument made of wood and metal resembling a xylophone came into use. In the early 17th century, a xylophone with keys in place of wooden bars was invented by Francesco. The instruments are often melodic percussion instruments, but they can also be treated as timpani.

electrical outlet box for fire rated wall|washing machine recessed wall box