threaded holes in sheet metal $82.82 If you go to the mfg website you can normally find a conduit fill table (for Crouse Hinds it's document IF964) that gives the wire size and max number by condulet style.

0 · thread engagement sheet metal

1 · sheet metal tapping thread

2 · sheet metal tapping metric

3 · sheet metal tapping guide

4 · sheet metal tapping

5 · how to cut threading inserts

GreatBuddy 2 Pcs Coco Liners for Planters 24 Inch, Sturdy Window Box Liners, Perfect Planter Liners Replacement for The Old, 100% Natural, Easy to Straighten Out

Threaded studs work great by allowing you to loosely hold or hang everything in position while you tighten the nuts. If you’ve ever tried to hold a heavy or awkwardly shaped part against a vertical surface while trying to align holes to get bolts in place, you understand the .View the specifications, design guidelines and best practices for tapping services . Threaded inserts, also known as threaded bushings or threaded sleeves, are used to provide a strong and secure threaded attachment point within a material that is too thin or .2.72

thread engagement sheet metal

sheet metal tapping thread

.82.29View the specifications, design guidelines and best practices for tapping services for your laser cut projects. Learn about thread types, hole sizing and more.

Threaded Inserts for Metal. Because metals like aluminium and steel are harder than wood, thread inserts for metal feature external as well as internal threading to make insertion and removal easier. The outer threads on .

Tapping in sheet metal is the use of a tapping tool to form material in a pre-punched or extruded thru hole, to create threads for engagement of a non-self-tapping screw. . Threaded holes are holes with internal threads created using threading tools such as taps, thread mills, or with the aid of threaded inserts. In engineering, fastened parts aren’t complete without threaded holes. Threads . Threaded holes are circular holes with internal threads. A threaded hole can have threads made by tapping or threading since there are several ways of making threads in a hole. Machinists often use a cutting tap to make these .

cnc sand casting parts

sheet metal tapping metric

cnc router parts store

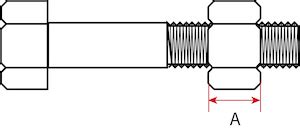

Threaded holes are integral aspects of mechanically fastened parts. They are easy to add with CNC machines. Threads are usually added last, after most other aspects of the part have been machined. Getting it wrong and . A threaded hole is a circular hole with an internal thread obtained by drilling the part using a die tool. Creating the internal threading is achievable using tapping, which is important when you cannot use bolts and nuts.Approximate Pilot Hole Sizes for Type A Steel Sheet Metal Thread Forming Screws. Steel, Stainless Steel, Monel Metal, Brass, and Aluminum Sheet Metal. Screw. This is sort of a design question, but I need to make threaded punched holes in sheet metal, something like this. I am unsure about how the process of making this. Would I need a guide hole before punching and what .

Explanation: Pitch: Designated by “X P“.For example, M8 X 0.75 means an 8 mm (0.315″) thread with a pitch of 0.75 mm (0.03″ or 34 TPI).If the “X P” is omitted, the pitch is defined by the Coase Pitch Series according to ISO-261. Number .

In sheet metal part designs, consider hardware material and placement. These choices, plus the connectors and material compatibility are pivotal to final parts. . so it is difficult or impossible to thread holes in the metal. This is why these . When threaded holes are made, first a hole is drilled, then a counter sink is put on the top of the hole to guide the tap(and it looks/feels nicer), then the hole is tapped with the correct thread. A tap is not going to drill a hole out bigger. . How thick is the part that has thread cut in it? Is it just a sheet metal bracket that is thin .Rivet Nuts: This method involves the use of rivets or similar fasteners to secure a threaded nut to a sheet metal part. Nuts provide a threaded connection for a bolt or screw. . For extrusion tapping holes in sheet metal parts, the material of the sheet metal itself is the primary consideration. Commonly used materials for sheet metal parts .

Drill a new hole at correct location; Tap hole for correct thread; Prime and paint; Plan B. Buy a helicoil insert of an appropriate size. Drill the hole out to the larger size needed. Tap the hole for the larger thread. Insert the insert. Plan C A tapped hole is simply a type of threaded hole. More specifically, it is a threaded hole produced by using a tap. These tools consist of a rod with sharp edges or teeth that cut into the sides of holes, forming internal spiral grooves (threads) as they cut away material. Tapping is a fast and convenient way of threading a hole and is one of .Mate leads the punching industry with a tool system designed to produce threaded holes in previously punched or extruded holes, in all types of sheet metal. Called EasyTap™, this unique tool system extends the punching capabilities of today's CNC punch presses by producing precisely located threaded holes at high speed, automatically and with repeatable quality

sheet metal tapping guide

That being said you’ll still want to reference our hole size chart when calculating the minimum distance required from other cut features. We’ll need the center of any tapped holes to be at least the following distance from other cut features: tap hole size/2 + the minimum tap hole-to-edge distance for the chosen material.

Self-tapping screws require a pre-drilled hole or core hole. They cut the thread themselves when screwing in and save the use of a tap. In principle, you always have to pre-drill for sheet metal screws.

Tapping a Hole in Laser Cut Sheet. Thread starter CatMan; Start date Jul 22, 2019; Replies 13 . Do you 5/16 hole size for 50% thread engagement. Use a decent quality tap. Go to town. We've tapped thousands of laser cut holes. . tapping mild steel sheet metal - cutting vs forming tap MooseKnifeCo; May 22, 2024; General; 2. Replies 24 Views 1K.

Pilot Hole Sizes for Steel Sheet Metal Crews in Sheet Metal ; Sheet Metal Self Threading ANSI Screws Dimensions for B and BP Threads; Sheet Metal Thread Dimensions for Types AB, A and U Thread Forming Tapping Screws ; Maximum tightening torque for metric self tapping screws; Self Tapping Screw Pull-Out and Torque Calculator Learn essential guidelines for machining threaded holes to ensure optimal performance and structural integrity in your mechanical assemblies with expert CNC machining advice. . Sheet Metal, DMLS and Tooling. 2-4 hours for most 3D Printing. If we have any questions, we will reach out to you! STEP files are the preferred format. Submit RFQ. All . These inserts are designed to provide a secure and reliable means of creating a threaded hole in thin sheet metal. Whether you are working with aluminum, steel, or other sheet metal materials, knowing how to choose and install the right threaded insert is essential for ensuring a strong and durable connection.

Folks, I have been trying to do the simple task of putting a #10-24 threaded hole in a boss on a sheet metal part. I use Hole Wizard, define the threaded hole and locate it accordingly.Tapped holes are formed threads in sheet metal used to thread a screw or bolt through to hold a component or attached the sheet metal part to another part. 704-825-1599 Email Us. Login. Cart (0) . Tapped holes are made in sheet metal parts by first starting with a laser cut hole. That hole is then treated with a treading bit to create threads .

Tapping 6-32 Threaded Holes in Thin Sheet Metal Part Tip to Help Not Break Tap

cnc router table parts

A threaded hole is a circular hole with an internal thread obtained by drilling the part using a die tool. Creating the internal threading is achievable using tapping, which is important when you cannot use bolts and nuts. Threaded holes are also referred to as tapped holes, i.e., holes suitable for connecting two parts using fasteners. Joshua, My question is, Why? If one is holding two or more pieces of sheetmetal together with a screw, either (A) one uses a sheetmetal screw that forms its own threads or (B) you use a press-in threaded insert (PEM being a very common brand) or you pierce-form an elongated piece in the sheet (a die-forming operation not normally supported in cut & fold CAD .

STANLEY® Engineered Fastening's Spiralock® Blind Hole Threaded Standoffs are designed to be easily installed in drilled holes to securely mount thin metal sheets. . These standoffs install with a squeeze in punched or drilled round holes and become permanently mounted in the thin sheet or metal—with their heads flush with one surface of .

The size of the drill hole depends on the screw size and the material being used. For instance, a size-4 screw requires a 3/32-inch pilot hole, while a size-10 screw needs a 9/64-inch hole. Sheet Metal Screw Sizes and Drill Hole Characteristics Mate Precision Tooling's Mate EasyTap® tool system automatically produces threaded holes in all types of sheet metal in thick-turret punch presses. The threaded holes are produced in prepunched holes or in extruded holes located on the sheet. A tapped (or threaded) hole is a hole that has a thread. What Is the Tapped Hole Symbol? The symbol for a tapped hole depends on the standards used. For metric holes, the diameter symbol is replaced with an ‘M’. For example a tapped hole for an M8 bolt would be ‘M8’.

Now the already threaded holes I found so far have steel backing plates with a weldnut attached to them. Those will be much stronger then rivnuts attached to hole in plain sheet metal. Cargo mounts / seat and seat belt mounts will be the strongest tie in locations in the van. And those are "calculated" by Ford engineers and got signed off in .Weld to metal surfaces to add permanent threads. 534 products. . 130 products. Snap-In Nuts. Push into square holes in thin materials to add bolts for aligning off-center parts. 69 products. Rivet-Mount Nuts. Add threads in hard-to-reach areas and materials that are too thin to be tapped . Press nuts and retaining rings onto threaded .Thread Loop. A Thread Loop from Wilson Tool is a great solution for eliminating secondary operations where a threaded hole is required. –– Explore the different solutions to your common punching manufacturing applications: Connective Forms: Assemble parts without screws, welds and clips using punches and dies you may already have.

Learn how to drill a hole with threads successfully with this step-by-step guide. Get expert tips and advice on choosing the right tools, preparing the surface, and achieving a clean and precise hole for threaded fasteners. Don't let drilling with threads intimidate you – follow these instructions and master the technique with ease.

Get Competitive Quotes

threaded holes in sheet metal|how to cut threading inserts