does a metal junction box need to be grounded A metal junction box does not need to be directly grounded by the NEC, but it is recommended that they have a ground connection. If a metal junction box does not have a ground connection, there is an increased risk of .

The Manual Data Input Mode (MDI) is one of the modes your CNC machine can operate in. The idea is to enter g-codes on a line which are executed immediately by the machine–you don’t have to write an entire g-code program when a line or two will suffice.

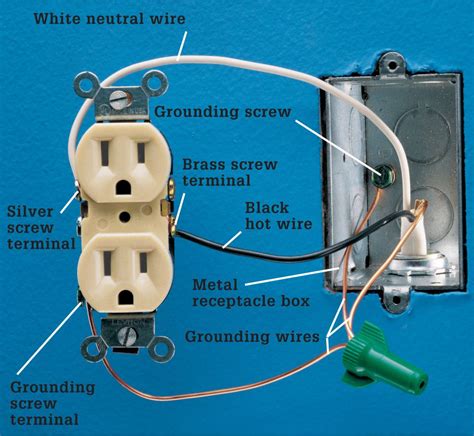

0 · wiring a receptacle metal box

1 · pigtail ground wire metal box

2 · grounding wire for metal box

3 · grounding screws for metal boxes

4 · grounding outlet to metal box

5 · grounding outlet into metal box

6 · grounding a receptacle metal box

7 · ground wire touching metal box

K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the material thickness where neither compression nor tension occurs during bending.

So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can be grounded and bonded via the conduit. If you were using nonmetallic conduit, you'd have to .You don't need a wire to ground the switch, the mounting screws satisfy the .

Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as . You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means . A metal junction box should be grounded to protect people from electrical shocks. The ground wire provides a path for electricity to escape if there is a problem with the wiring in .

A metal junction box does not need to be directly grounded by the NEC, but it is recommended that they have a ground connection. If a metal junction box does not have a ground connection, there is an increased risk of .It’s required by the NEC (National Electrical Code) to have junction boxes grounded, especially for metal ones. Grounding will always be a staple in every home’s electrical circuit because of the safety benefits. Note that non-metal .

Metal junction boxes are required to be grounded by connecting the grounding conductor to a grounding screw or other approved grounding method. You must install the grounding screw in a threaded or factory-made hole.

Panel feeds junction box with EMT-From JB to various loads with MC cable. The box is grounded via the EMT. If over 250 volts and concentric or eccentric KO's are used with . If a metal box is being used, best practice is to insert a green grounding screw into the threaded hole in the back of the box or enclosure. The equipment-grounding wires then connect to the screw, making the metal box . So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can be grounded and bonded via the conduit. If you were using nonmetallic conduit, you'd have to ground the boxes some how.

Plastic boxes, in general, do not need to be grounded. However, do bear in mind that such junction boxes cannot be used with metal conduit that is usually required outdoors or when wiring is exposed.

Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as the cable is properly secured to the box. You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches. A metal junction box should be grounded to protect people from electrical shocks. The ground wire provides a path for electricity to escape if there is a problem with the wiring in the box. Always be sure to ground a metal junction box properly. A metal junction box does not need to be directly grounded by the NEC, but it is recommended that they have a ground connection. If a metal junction box does not have a ground connection, there is an increased risk of electrical shock in your home.

It’s required by the NEC (National Electrical Code) to have junction boxes grounded, especially for metal ones. Grounding will always be a staple in every home’s electrical circuit because of the safety benefits. Note that non-metal junction boxes DO NOT need to be directly grounded.

Metal junction boxes are required to be grounded by connecting the grounding conductor to a grounding screw or other approved grounding method. You must install the grounding screw in a threaded or factory-made hole. Panel feeds junction box with EMT-From JB to various loads with MC cable. The box is grounded via the EMT. If over 250 volts and concentric or eccentric KO's are used with the EMT than a bonding jumper is required. The EGC within the . If a metal box is being used, best practice is to insert a green grounding screw into the threaded hole in the back of the box or enclosure. The equipment-grounding wires then connect to the screw, making the metal box part of the grounding system.

So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can be grounded and bonded via the conduit. If you were using nonmetallic conduit, you'd have to ground the boxes some how.

Plastic boxes, in general, do not need to be grounded. However, do bear in mind that such junction boxes cannot be used with metal conduit that is usually required outdoors or when wiring is exposed.

Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as the cable is properly secured to the box. You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches. A metal junction box should be grounded to protect people from electrical shocks. The ground wire provides a path for electricity to escape if there is a problem with the wiring in the box. Always be sure to ground a metal junction box properly.

A metal junction box does not need to be directly grounded by the NEC, but it is recommended that they have a ground connection. If a metal junction box does not have a ground connection, there is an increased risk of electrical shock in your home.It’s required by the NEC (National Electrical Code) to have junction boxes grounded, especially for metal ones. Grounding will always be a staple in every home’s electrical circuit because of the safety benefits. Note that non-metal junction boxes DO NOT need to be directly grounded. Metal junction boxes are required to be grounded by connecting the grounding conductor to a grounding screw or other approved grounding method. You must install the grounding screw in a threaded or factory-made hole.

Panel feeds junction box with EMT-From JB to various loads with MC cable. The box is grounded via the EMT. If over 250 volts and concentric or eccentric KO's are used with the EMT than a bonding jumper is required. The EGC within the .

wiring a receptacle metal box

cnc engraving machine sydney

cnc engraving and milling machine supplier

In a CNC machine, all tool movements and auxiliary machine functions (such as door open/close, spindle start/stop etc) are accomplished by a PMC. The CNC provides a .

does a metal junction box need to be grounded|grounding screws for metal boxes