cnc machine software validation Take an in-depth look at CNC machining, from milling to turning and prototyping to production. Our downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing . Auger Gear Box - The auger gear box has been factory lubricated for life. If for some reason lubricant should leak out, have the auger gear case checked by a competent .

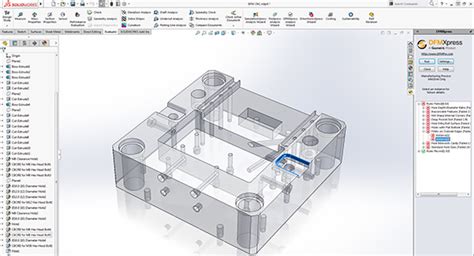

0 · solidworks cnc validation

1 · protolabs cnc machining guide

2 · predator virtual cnc software

Heat loss in houses is mostly through movement of air through the house (draughts) and conduction through the walls, not direct radiation through the windows. Shutters in winter would still be counter-productive if you have modern windows; sunshine through the windows is still significant in heating a house on sunny days.

One way to achieve this is through the implementation of a comprehensive CNC machine validation format. In this blog post, we will explore the importance of such a format and discuss .

CNC machine validation is a systematic process of verifying and documenting .

The standard cites a requirement for software validation in multiple places, including 4.1.6 (general requirement for software validation in support of the QMS), 7.5.6 (for .

Take an in-depth look at CNC machining, from milling to turning and prototyping to production. Our downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing .Predator Virtual CNC software is designed to simulate and verify operation of your CNC machines on your PC. By simulating the machining process offline, you save money, lost time, scrapped parts, broken tools and machine crashes while . All CNC programs must be verified. While new programs present more challenges than proven programs, operators must be careful and alert during every step of a program's .G-code verification includes a full CNC program and macro decoding and validation with automatic programming error detection, interactive tool path tracing, interactive machine display, and delivers the accurate machining cycle .

CNC machine validation is a systematic process of verifying and documenting the performance, accuracy, and reliability of computer numerical control (CNC) machines. It involves rigorous . Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world .

Mastercam. Mastercam is the most popular Computer-aided-manufacturing software used in the manufacturing industry. It provides an extensive set of tools for toolpath generation .emulation of the entire machine tool and Computer Numerical Control (CNC) controller, the prototype model provides the manufacturing data validation system with following list of . *) Process validation is per process. I recommend - in the context of process validation - that you focus on those machine runs that are serial production of significant counts (i.e. >100). - The DMR should contain everything that is required for making a conforming device; regardless of who designed it, or is regulatorily responsible.

All Topics Machine Tools Tooling Software Measurement Automation . All Topics See All . Additive Manufacturing Aerospace Automation . Not all CNC machines provide toolpath display, and it is difficult to see a program's true motions by watching a CNC machine run a program. You may not be able to achieve the objective of Step 1 in this .I have an idea for a CNC machine. Need validation from real machinists/shop owners . So couple years ago, during pandemic, I had an idea for a new type of CNC machine. I have CAD models of the machine and its variants, and even built a couple desktop-size working prototypes. . Look at software locks, manuals not being provided, safety and . With regard to medical devices and components, I am very much familiar with Process Validation on Injection Molding processes. Typically Time, Temperature and Pressure are the main factors adjusted for Par High and Par Low runs to optimize nominal parameters. I now find myself in uncharted. I built my own DIY CNC machine from scratch, welding metals to make a rigid CNC body, and making CNC control systems for powerful motors. I gained unique experiences both building and working with that CNC machine, and I’ve also published brand-new research on how to cheaply cut granite and stone with a unique trick (check my guide for this).

electric linch box

Digital twins validate and extend real-world CNC machines, making the creation and use of these simulations a worthwhile investment for machine shops and their customers. Digital twins offer functionality beyond parts program validation, .© 2024 CNC Software, LLC. All rights reserved.

Section 4: Validating CNC Machine Software and Programming . Importance of validating machine software . Verifying CNC machine programming accuracy . . By prioritizing CNC machine validation, manufacturers can stay ahead in the competitive manufacturing landscape and deliver exceptional products to their customers. (Note: The article has been .

1. Understanding CNC Machine Validation:\ CNC machine validation is a systematic process of verifying and documenting the performance, accuracy, and reliability of computer numerical control (CNC) machines. It involves rigorous testing and inspection to ensure that the machines are operating within acceptable tolerances and meeting the desired .

electric heating lunch box philippines

the machine is PVC tube cutting machine that produce tubing for medical device. it uses encoder to control the length of tube. Yesterday, our validation compliance advised to perform re-validation for the relocation however not clearly stated in the ISO 13845 in which condition to perform re-validation due to relocation.Trace-A-Matic provides comprehensive CNC inspection services, ensuring machined parts and assemblies meet or exceed your specifications. . Trace-A-Matic is a CNC machine shop recognized for world-class precision machining by leading OEMs. Our manufacturing takes place upon a solid foundation of quality control, backed by a comprehensive AS . For larger machines it may be more practical to use a modular artefact with a number of sections mounted to the machine-tool structure; in such a case it is important that effects such as thermal deformation or impacts do not cause errors in the machine-tool structure to be mirrored in the artefact.A. Robust programming and software validation\ B. Regular maintenance and inspection routines\ C. Proper tooling selection and setup\ . In conclusion, CNC machine crashes are an unfortunate and costly reality in various manufacturing settings. By understanding the causes, recognizing the risks involved, and implementing preventative measures .

MSC 953110 9″ x 42″ Vertical Milling Machine w/ Anilam Wizard 100 DRO $ 4,950.00 Add to cart; MSC 9″ x 42″ Vertical Milling Machine $ 4,250.00 Add to cart; MSC 9″ x 42″ Vertical Milling Machine w/ Acu-Rite MillMate DRO $ 4,950.00 Add to cart; Bridgeport Series I 9″ x 42″ 3-Axis CNC Vertical Milling Machine $ 14,500.00 Add to cart Verification vs Validation Protomatic does an installation validation on all CNC equipment installations. Parts are then verified with another means such as a Coordinate Measurement Machine (CMM) or other instruments. We . The Basics of CNC Simulator Software . A CNC simulator is a way of simulating G-code and toolpaths to predict the behavior and outcome of machining processes. With simulator software, you can simulate G-code . In part one of our three-part blog series, we looked at the rules of design for manufacturing (DFM) for the injection molding process.Specifically, what validation checks can you run in SOLIDWORKS before you send our .

solidworks cnc validation

The original way to verify an NC program was to run it on the machine and hope you didn’t hear any loud thunks. Then along came offline verification programs such as Vericut (www.cgtech.com) and Predator (www.predatorsoftware.com) that allow NC programs to be verified – actually simulated – on a personal computer.Now it appears that verification is .Predator Virtual CNC™ 5 Axis 3D Machine Simulation and Verification for 2-5 Axis Mills, Lathes, Mill/Turns, Lasers, Waterjets and Routers. 5 Axis CNC machine simulation within Predator Virtual CNC™ is designed to support a wide range of 5 Axis CNC machines including: 5 Axis CNC Mills; 5 Axis CNC Lathes; 5 Axis CNC Lasers; 5 Axis CNC Waterjets

its kinda like a machine that a Salemens said would cut this would no problems, show you a demo at show running your part, only to take delivery of a machine and you have to cut you cuts in 1/4's even though you are using the same material, tooling etc, come to find out they called it inconell and it turned out it was really 304ss.DATRON next Control is the award-winning and easy to learn CNC software that Microsoft says is the Future of the CNC Industry. Skip to Main Content. 888-262-2833; . Contact Us Today To Learn More About Our High Speed CNC Machines. . This field is for validation purposes and should be left unchanged. For example, you have not validated the static ultrasonic cleaning and passivation process, or the tumbling, cleaning and passivation process, nor have you validated the following machines used in the manufacture of medical devices: CNC (b)(4) machine, CNC grinding machine, CNC (b)(4) machine, CNC turning machine, CNC milling machine, robotic . In today’s fast-paced manufacturing landscape, precision and efficiency are non-negotiable. That’s where NX CAM and the power of the digital twin come into play. In a recent webinar, we discussed how NX CAM accelerates processes for machine shops, and one critical advantage stood out: the ability to validate processes early using a digital twin.

Intelligent optimisation. Inspection Plus uses SupaTouch technology to intelligently minimise cycle times, increase productivity and deliver significant improvements in metrology.. Advanced functionality for ultimate process control . Compatible with all major machine tool controls and types, this machine-resident package – requires no other external peripherals.Go direct from design to CNC manufacturing. With KCD Software’s One-Button Machining, KCD’s Commander calculates and optimizes toolpaths, maximizes your material yield with True Shape Nesting and generates CNC machine code [G code] for your CNC router. Production speed and agility. Custom one-off pieces are easily modified in the KCD Parts .Optionally available software components; NC-based measuring cycles for measurement of the Kinematics of 4 or 5 axes milling machines; Measurement of the accuracy and correction of the kinematics of 1 or 2 rotary axes; Identification of machine problems caused by incorrect machine settings, collisions or wearA calibration process of DMG Mori CNC machine Key Takeaways are: Understanding CNC Machine Structure: The structure of a CNC machine is complex, with several key components including the control software, drive system, linear guides and ball screws, spindle, tool length sensor, and coolant system. Each of these components plays a crucial role in the machine’s .

protolabs cnc machining guide

electric junction box for electric motors

Size is crucial because, Delgado says, litter boxes ought to be one-and-a-half times a cat’s length to provide ample room to dig, eliminate, and bury. On the other hand, plastic isn’t as.

cnc machine software validation|predator virtual cnc software