cnc machine definition pdf The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining .

Rusty hinges, deteriorating finish, and inconvenient dents can make for a toolbox that's in less-than-ideal shape, and, in many cases, there's not much you can do to fix it back up.

0 · what does cnc machine mean

1 · understanding cnc machines

2 · types of cnc machines

3 · how does a cnc machine work

4 · how cnc machine is controlled

5 · cnc machine used for

6 · best cnc machine for woodworking

7 · basic knowledge of cnc machine

Your pilot-hole drill-bit size will depend on the size of your sheet metal screw. A size-4 screw should have a pilot-hole drill size of 3/32 inches; size 6, 7/64 inches; size 8, 1/8 inches; size 10, 9/64 inches; size 12, 5/32 inches; .

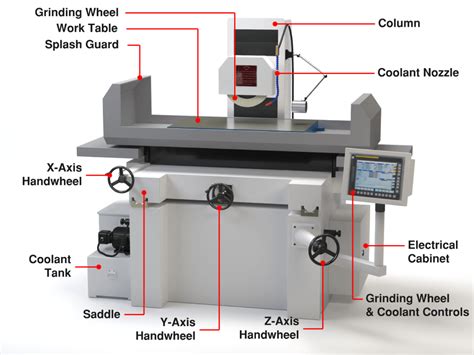

A CNC milling machine consists of the machine base and moving axes, a computerized controller, and some form of spindle to rotate the cutter or part. These machines are run from data either programmed in by hand, or created by a CAD/CAMThe term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process which typically employs computerized controls and .

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can .Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. .The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining .

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .

What is a CNC Machine? Conventionally, an operator decides and adjusts various machines parameters like feed , depth of cut etc depending on type of job , and controls the slide .

We now have the ingredients for a true CNC machine: data storage and transmission; precise motion control and positional measurement; and a computerized system that provides analysis .A CNC milling machine consists of the machine base and moving axes, a computerized controller, and some form of spindle to rotate the cutter or part. These machines are run from data either programmed in by hand, or created by a CAD/CAMThe term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process which typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame) CNC fabrication machines (sheet metal punch press,

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.What is a CNC Machine? Conventionally, an operator decides and adjusts various machines parameters like feed , depth of cut etc depending on type of job , and controls the slide movements by hand. In a CNC Machine functions and slide movements are controlled by motors using computer programs. It was in 1947 when numerical control was born.

We now have the ingredients for a true CNC machine: data storage and transmission; precise motion control and positional measurement; and a computerized system that provides analysis and optimization of the point-by-point tool path needed to make a three-dimensional shape.A CNC milling machine consists of the machine base and moving axes, a computerized controller, and some form of spindle to rotate the cutter or part. These machines are run from data either programmed in by hand, or created by a CAD/CAM

what does cnc machine mean

The term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process which typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank orThis course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame) CNC fabrication machines (sheet metal punch press,What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.What is a CNC Machine? Conventionally, an operator decides and adjusts various machines parameters like feed , depth of cut etc depending on type of job , and controls the slide movements by hand. In a CNC Machine functions and slide movements are controlled by motors using computer programs. It was in 1947 when numerical control was born.

electric box 31 help

electric box 2 level 8

your first guess is more like it, 1.6 could be used for structural sections of the body, e.g. chassis rails. 16g will do nicely for the floors and chassis but it will take some beating into .

cnc machine definition pdf|how does a cnc machine work