sheet metal finish Sheet metal finishing applies protective or decorative coatings to metal parts through chemical, mechanical, or electrical processes. The metal surface undergoes preparation, treatment, and . What do metal stars on houses actually mean? These metal stars allegedly originate from German settlers who came to Pennsylvania between 1727 and 1775, all of whom emigrated from the Rhine region of Germany.

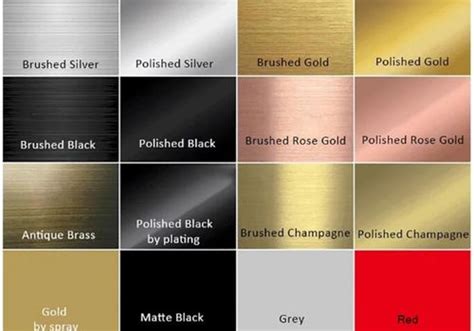

0 · types of metal finish chart

1 · stainless steel brushed finish chart

2 · sheet metal surface finish chart

3 · sheet metal finishing process

4 · sheet metal finish chart

5 · metal finishing specifications chart

6 · ceramic finish for stainless steel

7 · 304 stainless steel finishes chart

18 gauge is fine for most American 1950s-1960s cars. I don't know about '30s-'40s cars. You would not want to go thinner. I've used 20-gauge (thinner) for small areas but that was for convenience. All my patch panels and such are 18-gauge.

Surface finish is an essential consideration for many sheet metal fabrication projects—including, most commonly, parts requiring beautiful . There are many different ways to classify finishes for custom sheet metal parts. At Approved Sheet Metal, we’ve streamlined the options and . Xometry provides cosmetic and functional finishing for sheet metal, sheet cut, waterjet, and laser cut parts. See our description and image gallery for standard, bead blast, .

Sheet metal finishing applies protective or decorative coatings to metal parts through chemical, mechanical, or electrical processes. The metal surface undergoes preparation, treatment, and .Sheet metal finishing enhances both the appearance and functionality of metal parts. The right finish prevents rust, increases wear resistance and creates an attractive surface texture. Modern finishing techniques like powder coating, . In manufacturing and fabrication, sheet metal finishing is a critical process. How components made from metals look and their ability to function depend on this process. This definitive guide provides an inclusive view of different options for finishing by looking at methods such as anodizing, powder coating, or electroplating, among others.Finishing of sheet metal parts. There are several finishing techniques to get the perfect sheet metal finish that meets your needs. There is a wide range of finishes for stainless steels, such as the common 2D finish or a 2BA (Bright Annealed) finish that is made by brushes or a no. 5 with a Scotch-Brite belt. The deburring machines can be equipped with a Scotch-Brite belt, to add a .

Our sheet metal finishes vary in design but shall be used to achieve different visual effects and applications. The finishes deliver additional value due to improved appearance, corrosion resistance, and longevity. There are, however, differences in properties functionality, and finishing costs so it is essential to understand your specific needs for surface finish of .

types of metal finish chart

Sheet Metal Powder Coating & Plating. Approved Sheet Metal has powder coat capabilities in-house so you can get finished sheet metal parts FAST. We also have strong relationships with local platers so we can get parts completed in just days. We finish sheet metal parts in prototype and low volume production quantities.MFS has a highly skilled workforce, state-of-the-art sheet metal manufacturing equipment and a 30,000 square foot facility intended to handle small to large manufacturing scale. From cutting to bending to stamping to welding and finishing, if it can be done with sheet metal, we are the ones who can do it best. Different processing methods and cold rolling after processing, stainless steel surface can have different levels of surface finish, grain and color. The surface processing of cold-rolled stainless steel plate has 2D, 2B, No.3, No.4, 240, 320, No.7, No.8, HL, BA, TR hard state, embossed surface grade.MetalFinish LLC distributes and installs sheet metal deburring equipment to a variety of industries. With our stock of new and used machines, we have the capability to help you process metal parts of different sizes and configurations to get a uniform look and feel, with no burrs. . Contact Us: 860-747-6560 | [email protected].

A bronze finish provides a warmth that is unmatched by any other metal. Since these finishes are susceptible to oxidation, we protect the metal by applying clear finishes. Stainless Steel. . ASTRO SHEET METAL Co., INC. 1906 S. Great Southwest Parkway Grand Prairie, TX 75051. 972-438-1110. Monday – Friday 7:30am – 4:30pm.

stainless steel brushed finish chart

Stainless Steel 2B Finish Sheet Metal Supply and Metal Roofing. Sheet metal supply. Shipping available to all US states. Custom Architectural Sheet Metal Fabrication Our Craftsmen are Copper and Zinc Specialists! 15 Reardon Road - Medford, MA - 02155 Tel.: (781) 396-0070 .Stainless Steel 2B Finish: Pros and cons Pros. Enhances aesthetic appeal: The smooth, reflective surface is ideal for decorative and functional uses. Corrosion Resistant: A high chromium content provides excellent resistance to chemicals and moisture. Durability: Resists wear, providing long-lasting performance.; Easy To Clean: The smooth surface is ideal for food processing or .

This manufacturing finish for sheet metal is usually done when the base material is already suitable for the application environment. A good example is a stainless steel 316 part. Even used in a corrosive environment, it generally would not need additional finishing (apart from pickling and passivation) because the metal itself is well-suited .

The Mysteries of Metal Finishes. Ironically, though, the traditional oil and wax finishes which are most effective at achieving that goal, and most desired by knowledgeable clients and architects, are little understood by professionals and metal workers alike. As a result, there is a lot of mythology that surrounds such finishes, their . A: The most common metal finishes in sheet metal fabrication include powder coating, anodizing, plating (such as chrome or nickel plating), brushing, polishing, and painting. Indeed, each type of finish possesses different aesthetic and functional characteristics that make it suitable for various applications during the manufacturing process.

Each stage in the rolling and finishing process produces a salable sheet or plate with distinct finish and properties. Hot Rolled Steel. This is the most common and simple finish and the first step to making steel plates and sheets. A steel slab .Pyramid Fab and Finish is a full service manufacturer specializing in precision sheet metal fabrication & in-house coating services. Skip to Content 800.227.9058 [email protected] Request For Quote RFQOur guides include: Product Guide – Provides an inspiring overview of the different color solutions that Steelscape offers.; Color Design Guide – A comprehensive overview of modern color trends and finish options for metal .

round metal post brackets

Stainless steel is celebrated for its ability to resist corrosion, its long-lasting nature, and its modern look. This detailed guide examines the realm of stainless steel surface treatments, detailing the features, uses, and production methods of well-known finishes like No.1, 2B, BA, No.4, Anti-Fingerprint Hairline, and Mirror Finish.METAL FINISHING. Unlike most precision metal fabricators, EVS Metal has the ability to handle value-added finishing services such as wet paint and powder coating sheet metal finishing operations for fabricated metal parts, all in house. This allows us to better control quality, cost and lead times. EVS Metal – New Jersey:

Many industries, such as automotive and aerospace, rely on sheet metal to produce parts and components. And when it comes to the manufacturing process, sheet metal finishing is one of the most important steps to consider. Sheet metal finishes come in a variety of options and each has advantages and properties that set it apart from the others. Learning more about .304 Brushed Stainless Steel Finishing Sheet Metal Gap Filler Trim Strip Metal Trim for Home Kitchen Tools (Silver,1 x 30 Inch) 4.5 out of 5 stars 96 1 offer from 99 $ 18 99 It is particularly important to add a corrosion resistant finish to sheet metal parts that are used outdoors or in other environments where corrosion is a serious issue. Powder coating is an obvious example of a finish that increases corrosion resistance. By covering a sheet metal part in a powder coating, water and other substances that cause .

Line graining, or linear graining, is the process of adding a uniform surface finish to sheet metal parts. This is done by running the metal through a belt grinder. Applications for Linear Graining. Line graining adds a directional pattern and grained finish to steel or aluminum parts. Graining removes factory defects such as scratches, mill .Finishes. Polished Metals offers a superior finish that is consistent time and time again. We guarantee a uniform product each time, every time. Below is a listing of our most popular types of metal finishes. We can produce custom finishes and .Learn how sheet metal edits can be reflected in the folded view. but not the flat view with Onshape’s Finish Sheet Metal Model feature. Learn More. Tech Tip: How to Use Onshape’s Split Face Feature For Sheet Metal. 12/22/2020.Metal finishes come in a wide range of options, each creating a unique look and feel. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Anodizing creates corrosion resistance and adds vibrancy to the color while electroplating provides a durable finish with uniform coverage.

router cnc manufacturer

How to Choose metal surface finishes. Choosing suitable metal surface finishes is easy; all you have to do is consider specific factors. These factors include: Speed. Each metal surface finishes requires different time frames. Some are fast, while some are slow. Therefore, if you have a project to deliver, consider the time needed to deliver .

sheet metal surface finish chart

Question 1: What Gauge Steel Are Your Cabinets Made Of? The answer is simple: our cabinets aren’t made of steel - they’re made of high-quality wood. We have specifically engineered our cabinets to withstand the unique .

sheet metal finish|sheet metal finishing process