1970s cnc machines The 1970s saw the adoption of microprocessors, which improved the processing speed and capabilities of CNC machines. This led to increased precision, complexity, and versatility in . $9.99

0 · when did cnc machine evolve

1 · history of nc machines

2 · history of cnc manufacturing

3 · cnc machine history

4 · 1970s cutting tools

Accommodates two identical cutting processes or turnaround applications within a 10” chuck machine for utilization flexibility. Available with single, or twin gantry loaders, it can load/unload various sizes and weights for added versatility to meet all production time requirements.

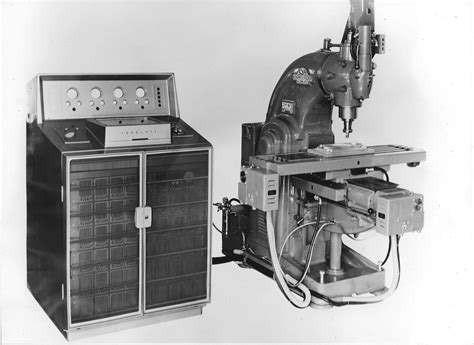

It was one of the first Computer Numerical Controls (CNC) on the market, and featured a PDP 8 minicomputer. For companies unwilling to discard their perfectly good .In the 1960s and 1970s, the introduction of computers to control the machine tools was a game-changer. The advent of microprocessors and digital technologies in the 1980s further .The 1970s saw the adoption of microprocessors, which improved the processing speed and capabilities of CNC machines. This led to increased precision, complexity, and versatility in .Advancements in Digital Control (1960s - 1970s) The 1960s brought significant advancements in digital control systems for CNC machines. The introduction of computers allowed for more .

At Bantam Tools, we create desktop CNC (computer-numerically controlled) machines with reliability and precision. We set out on a journey to explore the history of CNC. The comprehensive. CNC turning machines were created in the 1970s and 1980s, making it feasible to produce cylindrical parts with exceptional accuracy. These devices quickly gained popularity in the manufacturing sector because they .

The term “CNC” itself became more commonly used in the 1970s when computer technology and miniaturization advanced to a level that allowed for the integration of computers directly into machine tools.

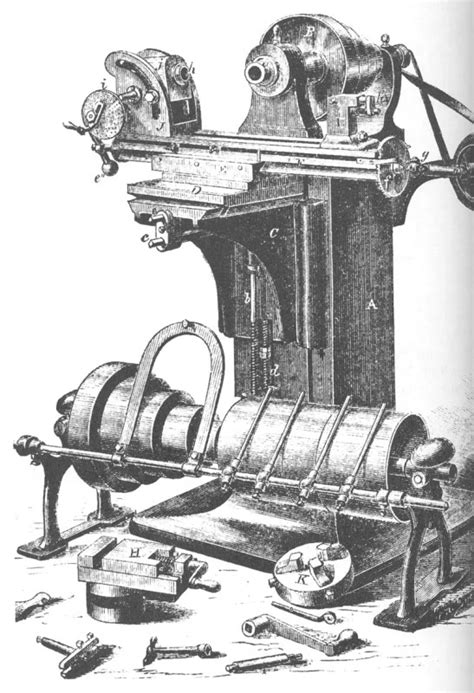

In this article, we'll delve into the fascinating history of CNC machining and explore its evolution, from its humble beginnings to its current state-of-the-art capabilities. 1. The Birth of Numerical Control. 2. The Emergence of Computer . In the 1970s, the introduction of microprocessors and digital control systems further improved CNC technology. The 1980s saw significant advancements in CNC machining technology. CAD (Computer-Aided Design) . It was one of the first Computer Numerical Controls (CNC) on the market, and featured a PDP 8 minicomputer. For companies unwilling to discard their perfectly good manual machines for new, more expensive, NC controlled systems, Robert R. Fuller Sr. had an answer.In the 1960s and 1970s, the introduction of computers to control the machine tools was a game-changer. The advent of microprocessors and digital technologies in the 1980s further accelerated the development of CNC machines, making them more powerful, versatile, and easier to use.

During the 1960s and 1970s, computer technology moved fast enough and was reliable enough for machine shops to begin adopting CNC machines instead of using the older NC systems. Without punch cards that required a flexowriter to create the program on the physical card or tape, CNC machinery could take less time to program software.The 1970s saw the adoption of microprocessors, which improved the processing speed and capabilities of CNC machines. This led to increased precision, complexity, and versatility in machining operations.Advancements in Digital Control (1960s - 1970s) The 1960s brought significant advancements in digital control systems for CNC machines. The introduction of computers allowed for more sophisticated programming and control capabilities. At Bantam Tools, we create desktop CNC (computer-numerically controlled) machines with reliability and precision. We set out on a journey to explore the history of CNC. The comprehensive.

CNC turning machines were created in the 1970s and 1980s, making it feasible to produce cylindrical parts with exceptional accuracy. These devices quickly gained popularity in the manufacturing sector because they made it simple to create accurate, complex pieces that could be produced repeatedly.

The term “CNC” itself became more commonly used in the 1970s when computer technology and miniaturization advanced to a level that allowed for the integration of computers directly into machine tools.In this article, we'll delve into the fascinating history of CNC machining and explore its evolution, from its humble beginnings to its current state-of-the-art capabilities. 1. The Birth of Numerical Control. 2. The Emergence of Computer Numerical Control. 3. The Integration of CAD and CAM Systems. 4. The Modern Era of CNC Machining. 5. In the 1970s, the introduction of microprocessors and digital control systems further improved CNC technology. The 1980s saw significant advancements in CNC machining technology. CAD (Computer-Aided Design) systems were introduced, which enabled designers to create complex 3D models on the computer, which could then be used to program CNC . It was one of the first Computer Numerical Controls (CNC) on the market, and featured a PDP 8 minicomputer. For companies unwilling to discard their perfectly good manual machines for new, more expensive, NC controlled systems, Robert R. Fuller Sr. had an answer.

In the 1960s and 1970s, the introduction of computers to control the machine tools was a game-changer. The advent of microprocessors and digital technologies in the 1980s further accelerated the development of CNC machines, making them more powerful, versatile, and easier to use. During the 1960s and 1970s, computer technology moved fast enough and was reliable enough for machine shops to begin adopting CNC machines instead of using the older NC systems. Without punch cards that required a flexowriter to create the program on the physical card or tape, CNC machinery could take less time to program software.The 1970s saw the adoption of microprocessors, which improved the processing speed and capabilities of CNC machines. This led to increased precision, complexity, and versatility in machining operations.Advancements in Digital Control (1960s - 1970s) The 1960s brought significant advancements in digital control systems for CNC machines. The introduction of computers allowed for more sophisticated programming and control capabilities.

At Bantam Tools, we create desktop CNC (computer-numerically controlled) machines with reliability and precision. We set out on a journey to explore the history of CNC. The comprehensive. CNC turning machines were created in the 1970s and 1980s, making it feasible to produce cylindrical parts with exceptional accuracy. These devices quickly gained popularity in the manufacturing sector because they made it simple to create accurate, complex pieces that could be produced repeatedly.

The term “CNC” itself became more commonly used in the 1970s when computer technology and miniaturization advanced to a level that allowed for the integration of computers directly into machine tools.

In this article, we'll delve into the fascinating history of CNC machining and explore its evolution, from its humble beginnings to its current state-of-the-art capabilities. 1. The Birth of Numerical Control. 2. The Emergence of Computer Numerical Control. 3. The Integration of CAD and CAM Systems. 4. The Modern Era of CNC Machining. 5.

small cnc router machine with automatic tool changer

when did cnc machine evolve

history of nc machines

Using a CNC turret punch press in sheet metal manufacturing offers several critical advantages, such as: Versatility and Shape Flexibility. As mentioned, a turret punch can create infinite sizes and shapes in soft metals because it uses multiple strokes for every cut.

1970s cnc machines|history of cnc manufacturing