cnc machine x y z axis In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . $23.98

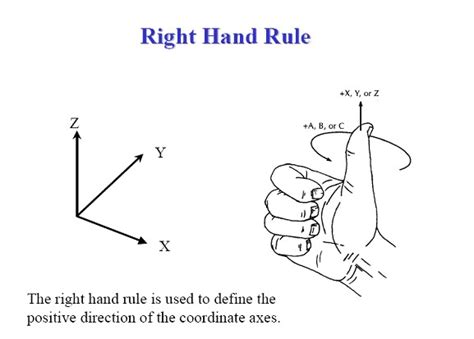

0 · cnc right hand rule

1 · cnc mill axis diagram

2 · cnc machine axis identification

3 · cnc lathe coordinate system

4 · cnc axis explained

5 · cnc axis diagram

6 · 5 axis vs 6 cnc

7 · 5 axis metal cnc machine

8 Pack White Storage Bins with Lids Stackable Storage Container for Organizing, Storage Boxes with Handle for Shelves, Cube Storage Bin for Craft, Snacks, 9.85x6.9x5.7 inch

Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis .In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. .

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool .1. What is the CNC Machine Coordinate System? Definition and purpose of the CNC machine coordinate system. Components of the coordinate system (X, Y, Z axes). Importance of . Fundamentally, CNC machines operate along three core linear axes: X, Y, and Z. These refer to back-and-forth (X), left-and-right (Y), and up-and-down (Z) motions on flat planes. Extra rotating axes labeled A, B, and C .

Axes of a CNC milling machine. Taking the most common vertical CNC mills as an example, 3 axes control the linear motion of the workpiece and the spindle, the X axis moves left and right, the Y axis moves forward and .While the X and Y axes control the horizontal movement of the cutting tool, the Z-axis controls the vertical movement, allowing for depth and thickness adjustments during the machining .

CNC Touch Probe Plate, X Y Z Axis Tool Setting, for Carbide Motion and Shapeoko 3 . Brand: Dog River Tools. 4.4 4.4 out of 5 stars 296 ratings . The tolerances are quite good, it is exactly 22 mm on the Z axis, and . Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. Why CNC Milling Machines are Precise . But not all CNCs have the linkage of A and C axes with X, Y, . I followed the set by set procedures to setup and calibrate Mach3 and my cnc machine. I also disabled the estop. Now when I try to move the x, y, or z axis my cnc machine will not move. when I plug in my parallel port and usb cable from my cnc box to my computer I hear a knock sound from all 3 motors telling me that the motors are starting up.

cnc right hand rule

According to ISO regulations, when describing the motion of CNC machine tools, the left-handed rectangular coordinate system is used; the coordinate axis parallel to the main shaft is defined as the Z axis, and the rotation coordinates around the X, Y, and Z axes are A, B, and C, respectively.In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary . This technique developed from the process of rotary filling, which uses just the X and Y-axis. In a 3 axis CNC machine, the three axes are the X-axis, the Y-axis, and the Z-axis. The X-axis moves left to right, the Y-axis moves from front to back, and the Z-axis moves up and down. A 3 axis CNC machine can work on each axis at the same time. Hi, I am fairly new to cnc carving. I am having problems with my x,y,z axis moving more than they should. This has only been a problem for a few days. I have a Fox Alien 4040-xe and use Easel to run my machine. My x,y axis is moving 5mm when set to move only one. the z axis is also off. set it to move 10mm it moves 39mm. Is there a solution for this?

I'm having an issue with the Cnc Shark hd3 at my local wood workers club. The x and Y axis's seem to be in calibration fine but the z axis seems to be out by a scale of 2.4. . At one time the sharks were all were .25 in/rev pitch and then later with the hd machines the x and y were .5 and the z was kept at .25 inch /rev. Did they change the Z . Standard 3-axis milling takes place on the X-, Y-, and Z-axes. These three linear axes are the directions the spindle or part—depending on the machine—can move: X-axis: Left-to-right; Y-axis: Forward-to-back; Z-axis: Up-and-down; Using all three axes at once, a machine can shave down material to create various three-dimensional objects.

1) You can change the dimensions in software so that X is 16" and Y is 36". This is what I do. It may require rotating your design to fit in the corrected dimensions. 2) If you can't wrap your head around the X/Y of the machine, you can swap the X and Y stepper motor cables. Turn off power to everything first and simply swap the cables.

Restart the machine and test it. If is currently set to anything else, then you'll need to refer to the PDF wabmester linked to to see what setting will preserve the X and Y but invert the Z. Hope this helps, good luck. Most hobbyist CNC routers have three axes, while 4 axis CNCs simply have an additional rotational axis to provide more efficient and versatile machining. A 3 axis router has X, Y, and Z axes for cutting flat 2D and 2.5D shapes: The X-axis moves left to right ; The Y-axis moves right to left ; The Z-axis moves up and down ; Whereas 4 axis CNC . I retrofitted a Excello mill that used the knee for z-axis with a 1990's version with a Centroid control. It had a 10 to 1 gear reduction as opposed to direct drive for the x and y axis. It takes more time to make the z axis moves, but I did not observe any accuracy problems with z axis movements. It worked ok for me for 10 years.

Hi all! I'm new to CNC machines, and have been searching the internet for details about how common (typical) CNC machines based on stepper motors control the x, y and z axis positions accurately. So far, I haven't yet found details that explain positional control.45, 46, 47 - Mirror Image X, Y, Z Axis. When one or more of these settings is ON, axis motion is mirrored (reversed) around the work zero point. See also G101, Enable Mirror Image. No Mirror Image [1], Setting 45 ON - X Mirror [2], Setting 46 ON - Y Mirror [4], Setting 45 and Setting 46 ON .

Measure the B- axis of rotation parallelism to the Y-Z plane: For a machine with a Classic Haas Control, change Parameter 151:20 (B axis CHK TRAVL LIM) to 0.. For a machine with a Next Generation Control, change Parameter 6.021 (B . Perhaps rapid to a location minus .025 in X and Y, then feeding the +.025 in X and Y, then boring.. might help. Years ago we had a job that was giving us fits. Was a waveguide housing with a bunch of close t/p .

cnc mill axis diagram

What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It Works. X-Axis: Moves the tool left and right. Y-Axis: Moves the tool forward and backward. Genmitsu CNC Router Machine PROVerXL 4030 XYZ Working Area 400 x 300 x 110mm (15.7''x11.8''x4.3'') . Y-axis Dual screw drive, Z-Axis Optical Axis Drive delivers more stability than the traditional v-slot drive. It's ideal for an endless variety of cutting, drilling, and carving operations on various materials including wood, MDF, plastics . I have a Woodworker x-50, with 16mm ballscrews on Y and X. After loading the new config, and setting the motors to 2000, the machine is moving correctly, however I see that the X axis is set to 0.629920, Y is set to 0.393701(This doesnt seem right.) and the Z is also set to 0.393701. My Y-axis screw is definitely is the same 16mm as my Y axis, yet setting the Y-Axis .The Z-axis is one of the three primary axes in CNC machines, along with the X-axis and Y-axis. While the X and Y axes control the horizontal movement of the cutting tool, the Z-axis controls the vertical movement, allowing for depth and thickness adjustments during the machining process. We will explore the fundamental components and .

The ST-40SY is a short-bed version of our large-frame ST-40Y lathe, providing the same shop-proven performance and reliability, with shorter Z-axis travel and a smaller footprint. The addition of Y-axis motion, C-axis interpolation, and live tooling allows milling, drilling, and tapping for increased machine capabilities. The C-axis can also be synchronized with the X and Z axes to facilitate multi-axis machining, further expanding the capabilities of the CNC lathe. In addition to these primary axes, CNC lathes may also have secondary axes such as the Y-axis or B-axis, depending on the machine's configuration. So in keeping with convention, the thing that moves closer to or farther away from the spindle is the Z axis. That's the carriage. Some lathes (cnc lathes) DO have a Y axis; the carriage has rise and fall for adjusting the centerline of tools and for doing off-axis live tool drilling. On a horizontal mill, it's the same way. Z is what most .

The axis is labeled (X, Y or Z). One point on the line is designated as the Origin. Numbers on one side of the line are marked as positive and those to the other side marked negative. . Fig. 3.5 X-axis number line (Image: “CNC Machine Tool Programmable Axes and Position Dimensioning Systems” by LamNgeun Virasak, Manufacturing Processes 4 .Example: To pair the 4th axis with the X axis AND pair the 5th* axis with the Z axis, the value entered into parameter 64 would be 49. (1 + 48) PID Configuration screen – From main screen F1 (Setup)->F3(Config)->F4(PID) For all system configurations, confirm that the values for slaved axis - 4th or 5th axis are identical to that of the master .CNC Z-Axis Sliding Table 3018 Engraving Machine Upgrade DIY Metal Kits, Stroke 90mm, Lead 4mm, Supporting Nema17 Stepper Motors, with Multifunctional Spindle Fixing Plate, Black Alumina Alloy . RATTMMOTOR ZBX150-300mm/11.81" Stroke CNC Linear Stage Motion Actuator X/Y/Z Axis Cross Sliding Table Double Linear Slide Rail Guide 1605 Ballscrew .

aluminum fabrication wv

aluminum fabrication springfield mo

$10.48

cnc machine x y z axis|5 axis metal cnc machine