90 angle electrical junction box inch and a quarter Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels. Easy assembly: Wooden slats are lightweight and easy to disassemble, making them easier to move than heavy, cumbersome box springs. Airflow: On a slatted bed foundation, air circulates freely around the mattress.

0 · nec junction box sizing chart

1 · junction box sizing requirements

2 · junction box sizing calculator

3 · junction box size chart

4 · junction box connectors

5 · junction box adapters

6 · electrical junction box size

7 · cross junction box sizing

$15.00

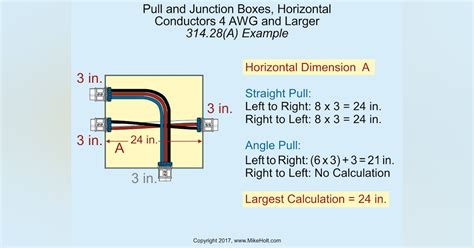

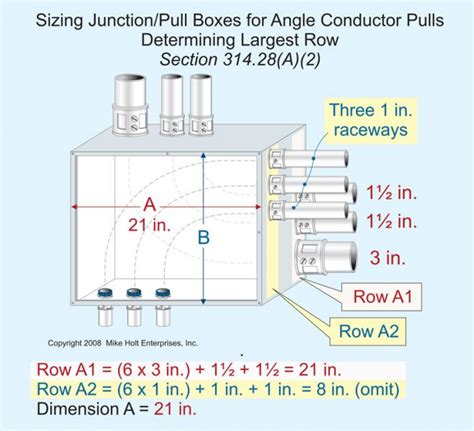

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels. Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch .

National Electrical Code or NEC limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. It specifically states, “There shall not be more than the .Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels.The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull . A junction box provides protection for these sensitive connections against bad weather, accidental contact, tampering and other hazards that can damage wiring. Below, we’ll .

By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

nec junction box sizing chart

Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels. Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.National Electrical Code or NEC limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. It specifically states, “There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.”Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels.

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28.

A junction box provides protection for these sensitive connections against bad weather, accidental contact, tampering and other hazards that can damage wiring. Below, we’ll talk about how to size a junction box appropriately and determine which attributes your junction box needs to have.

By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account several factors, such as the type of conduit, conductor size, and the number of conductors. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels. Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

National Electrical Code or NEC limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. It specifically states, “There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.”Create a tight grip on cords in wet environments while reducing stress from bending— the 90° angle of these cord grips routes cords to fit tight spaces in enclosures and panels.

junction box sizing requirements

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. A junction box provides protection for these sensitive connections against bad weather, accidental contact, tampering and other hazards that can damage wiring. Below, we’ll talk about how to size a junction box appropriately and determine which attributes your junction box needs to have.By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account several factors, such as the type of conduit, conductor size, and the number of conductors.

all in one cnc machine

all metal fabricators allen tx

Technological advancements, such as automation and computer numerical control (CNC), are playing a significant role in improving the quality and consistency of wood products. The .

90 angle electrical junction box inch and a quarter|cross junction box sizing