picking the right junction box When nailing the box, use light, careful blows rather than heavy swings of the . $16.99

0 · pvc junction box

1 · junction boxes for metal

2 · junction boxes explained

3 · junction box wiring

4 · junction box instructions

5 · how to install junction box

6 · electrical junction box installation

7 · electrical junction box

There is a junction box in front of the passenger side rear tire that is leaking break fluid. What is that box called?

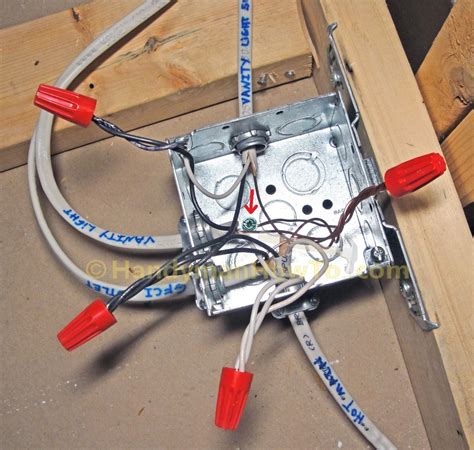

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple .

When nailing the box, use light, careful blows rather than heavy swings of the .Plastic Box: Metal Box: Use with plastic-sheathed cable: Use with metallic .Once the hole is cut in the wall for the box, feed the cable (or cables) out through .Correct fill capacity: The junction box should be large enough to contain the wires. .

To install this type of clamp, insert the threaded end into a knockout hole in the . Selecting the right electrical box for your project can be confusing because of the many options available. Whether you’re starting new .

Unlock the essentials of junction boxes with Vorlane's guide on types, uses, and installation tips for safe and efficient electrical setups. Selecting the right electrical junction box is a vital step in ensuring your electrical system’s safety, functionality, and longevity. With various .

Metal junction box cover screw sizes vary depending on the type of box and its application. The most common screw sizes for metal junction boxes are 6-32, 8-32, and 10-32. The 6-32 screw size is commonly used for outlet screws and cover plates, while 8-32 is often used for light fixture screws and junction boxes that need to support more weight.

Junction boxes are a necessity in most EEE and IoT devices that you use on a day-to-day basis. It is one of the most important parts of an electrical device from a security standpoint. IoT and EEE device companies need to make a lot of . If you have a device (switch) box, you'll typically find that screws sized 6-32 are used. For junction boxes, which are commonly used for ceiling fans, the standard screw size is 8-32. It's worth noting that 6-32 screws may be considered a bit light for a ceiling fan, so opting for 8-32 or even 10-32 screws can provide a more secure . Standard Screw Sizes for Junction Boxes: The most commonly used screw sizes for junction boxes are #6 (3.5mm) and #8 (4mm). The length of the screw will depend on the specific box size. For smaller junction boxes, screws with a length of 0.75 to 1 inch (19 to 25mm) are typically used. Larger junction boxes may require longer screws, usually .

To determine the right junction box, you need to consider several factors. Assess the size of your electrical installation. Decide how many wires and their sizes you will connect in the junction box. . Choosing the right connection box for your facility is essential for maintaining the safety and efficiency of your electrical systems. You can . Choosing the Right Junction Box for Outdoor Use Materials Matter. The material of your junction box is a crucial factor in durability and protection. Let’s explore some of the best materials available: Polycarbonate; Polycarbonate junction boxes are lightweight, impact-resistant, and offer excellent UV resistance. This makes them a popular . Solar panel systems are revolutionizing how we generate and consume energy, offering a sustainable and cost-effective alternative to traditional power sources. However, the efficiency and safety of a solar panel system depend on various components working seamlessly together. One such crucial component is the junction box. But what exactly is a junction box, .Understanding the Junction Box. Junction boxes play a significant role in optimally operating your solar panel. Although these boxes are often overlooked pieces, they form the backbone of the panel, delivering reliable results and linking crucial electrical components. One of the major purposes of the junction box is to maintain the flow of .

If you need a slightly larger screw, you can opt for #8 (4mm) or #32 screws. For larger junction boxes, #8 (4mm) or #10 (5mm) screws with a length of 1.25 inches (32mm) or longer are more suitable. It's always recommended to refer to the manufacturer's guidelines and local building codes to determine the exact screw size for your junction box . Drilling junction boxes is a crucial skill for electricians and DIY enthusiasts alike. Whether you’re installing new electrical circuits or repairing existing ones, knowing how to drill junction boxes properly ensures safety and efficiency. In this comprehensive guide, we’ll walk you through the entire process, from selecting the right tools to making the perfect hole. Modern electrical systems depend on various equipment and accessories to function properly. Among them, one such equipment is a junction box. Junction boxes are an important part of an electric. Introduction: The Importance of Choosing the Right Junction Box Supplier. Junctions boxes are an absolute necessity for IoT and EEE devices. Considering the security standpoint of commercial and industrial infrastructure, this electrical equipment can impact safety on a day-to-day basis if not sourced from certified supplies.

In this blog post, we will explore the differences between junction boxes and terminal boxes, their unique features, and the appropriate situations for their usage. Junction Boxes: A junction box is a standard enclosure crafted from metal, plastic, or fiberglass, designed to safeguard electrical connections and house wires within a concealed space.Bud offers a stainless steel enclosure that is lower in cost than most. Typical applications include instrument cases, control housings, terminal wiring enclosures, meter cases, junction boxes, and marine applications. Formed by .

Screws for junction boxes. Junction boxes usually require heavier-duty screws than other electrical boxes. The most common screw size for junction boxes is 8-32, but 6-32 or 10-32 screws can also be used depending on the specific application and weight requirements. . By choosing the right size and type of screws for junction boxes, you can . The type of electrical cable used is another important factor in selecting the right box. For non-metallic cable installations, plastic or metal boxes can be used, while metal conduit installations require the use of a metal box. . Octagonal boxes can be used as junction boxes. When choosing an electrical box, it is important to consider its .110.3 says it needs to be listed for the application, and much the same as other junction boxes, there's not much in the way of excluding making your own holes 314 says in order to use it as a junction box that contains splices the body has to be stamped with the amount of cubic area, but that doesn't exclude making holes in the side and adding . One of the first steps in choosing the right junction box is understanding the different types available. Junction boxes come in various sizes, materials, and designs, each suited for specific environments and electrical demands. Plastic Junction Boxes: Ideal for .

The screw size required for a junction box can vary depending on the specific box and its application. In general, device (switch) boxes typically use 6-32 screws. For junction boxes, the standard screw size is 8-32. Ground screws, on the other hand, require a .

pvc junction box

When installing a new fan or light fixture, it is important to use the correct size of screws to ensure a secure fit. 8-32 screws are commonly used for junction boxes and other electrical boxes that require larger screws. Junction boxes are often found in older houses and can vary in size, but a standard 4x4 junction box will typically use 8-32 . Whether for outdoor installations, bathrooms, or any area prone to moisture, choosing the right waterproof junction box is key to maintaining a secure and reliable electrical setup. Necessary Tools and Materials. Before embarking on a junction box installation, ensuring you have the necessary tools and materials is fundamental for a successful .

The Spruce / Margot Cavin. Best for: Multiple electrical devices encased together Like standard rectangular boxes, gangable electrical boxes hold household switches and electrical outlets.Still, they are oversized so that two, three, or four devices can be mounted side-by-side. Choosing the Right Junction Box. The appropriate junction box type depends on the specific installation requirements and preferences. Consider the following factors when selecting the box: Size: Choose a box with sufficient space to . Choosing the right electrical junction box is essential for the safety and efficiency of your electrical system. An electrical junction box is a protective enclosure used to house electrical connections, keeping them safe from external elements and preventing electrical hazards. When selecting a junction box, consider the material.

Why is it so important to choose the right junction box to safeguard these components from the hot sun, cold winds and precipitation?. UV rays and high temperatures can cause device components to overheat, melt or otherwise deform.; Water and condensation inside the enclosure can cause device malfunctions and damage electrical connections.; Low .

Finding the Right Electrical Junction Box Size. Choosing the correct size for a junction box ensures that it can accommodate all the wires, connections, and any other components without overcrowding or risking overheating. Proper sizing is essential for safety and adherence to electrical codes.

how to splice inside a junction box

Metal boxes are a good choice for high-current applications, while plastic boxes are more suitable for corrosive or damp environments. Plastic electrical boxes are the most common type of electrical box. They are made from a variety of materials, including PVC, .

picking the right junction box|junction boxes explained