diy cnc mill parts Here’s a cutaway of a cartridge spindle set up for ATC (Automatic Tool Changer) so . Fisheries Supply offers a variety of electrical marine products, including the high-impact plastic Newmar Waterproof Junction Boxes. Select a type and shop now!

0 · make your own cnc mill

1 · homemade cnc milling machine

2 · diy desktop cnc mill

3 · diy cnc mill kit cost

4 · diy cnc mill kit comparison

5 · cheap desktop cnc mill diy

6 · build your own milling machine

7 · build your own cnc mill

20 Inch Steel Portable Tool Box - 3 Drawer+Top Storage Toolbox with Lockable Metal Latches for Household Workshop Repair Shop, Red/Black, TOOLS-00407

make your own cnc mill

Click the menu above to scroll to a particular part of a typical CNC Milling Machine. You’ll get a brief overview of the part together with links that let you drill down and discover .Here’s a cutaway of a cartridge spindle set up for ATC (Automatic Tool Changer) so .

cnc dot stamper

Probably the most imporatant part of the CNC Machine and the most challenging to implement. I will try to make it easy for you by offering the common component that can be used in your .For three months I tried to find the proper parts (A dremeltool, drawer slides, pieces of wood, etc.), but I didn't really know how to build a CNC. The idea fell .Learn about the different types of spindles, bearings, tapers, and tool holders for your DIY CNC project. Compare cartridge, self-contained, and fabricated spindles .

IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the .For the DIY CNC router, mill, lathe, or robot! Only top-quality components from major manufacturers. Drive 3 or 4 steppers at up to 3 amps each. Since 1999, HobbyCNC has been selling a variety of high-quality DIY hobby CNC .

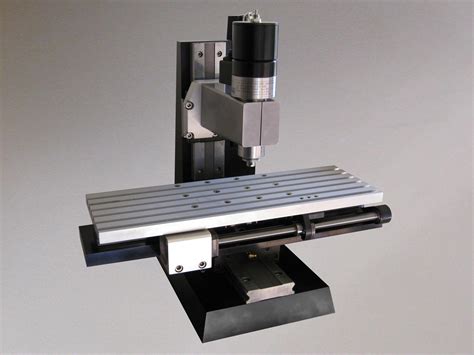

Building your own DIY CNC milling machine is a challenging but rewarding project that will give you the freedom to create custom metal parts with precision and efficiency. With our step-by .First things first, buy and assemble a router. I bought the CNC 2417 Mini. There are lots of different models out there. Some of them come with a Laser module too. Just mind to pick one that matches these table slots, if you do not want to .Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, .

Click the menu above to scroll to a particular part of a typical CNC Milling Machine. You’ll get a brief overview of the part together with links that let you drill down and discover more detail about the CNC Mill Part. Use the Guide as an aid to help you make good design choices for your own DIY CNC Milling Machine project.Probably the most imporatant part of the CNC Machine and the most challenging to implement. I will try to make it easy for you by offering the common component that can be used in your DIY CNC Router. These parts are especially selected to work with motors used in the DIY community and took me quite a while to find the perfect combinations.For three months I tried to find the proper parts (A dremeltool, drawer slides, pieces of wood, etc.), but I didn't really know how to build a CNC. The idea fell into oblivion. In August 2013 the idea to build a CNC milling machine captivated me again. Here’s a cutaway of a cartridge spindle set up for ATC (Automatic Tool Changer) so you can get an idea of the components: CNC ATC Cartridge Spindle. Let’s go over the role of each component: Angular Contact Bearings: This particular spindle has two angular contact bearings plus two deep groove ball bearings (salmon colored).

IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only .For the DIY CNC router, mill, lathe, or robot! Only top-quality components from major manufacturers. Drive 3 or 4 steppers at up to 3 amps each. Since 1999, HobbyCNC has been selling a variety of high-quality DIY hobby CNC products: Stepper motor controller kits, DIY CNC router plans and stepper motors for the desktop machinist and DIY hobbyist.Building your own DIY CNC milling machine is a challenging but rewarding project that will give you the freedom to create custom metal parts with precision and efficiency. With our step-by-step guide, you'll have the knowledge and confidence to take on .First things first, buy and assemble a router. I bought the CNC 2417 Mini. There are lots of different models out there. Some of them come with a Laser module too. Just mind to pick one that matches these table slots, if you do not want to re-design my 3D parts. It's like lego, you see the picture and you build it.

Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.Use the parts list on pages 19-22 of the instruction PDF to order all the parts, hardware and stock you'll need. The MDF and some hardware can probably be sourced at lower prices from a local hardware store. Click the menu above to scroll to a particular part of a typical CNC Milling Machine. You’ll get a brief overview of the part together with links that let you drill down and discover more detail about the CNC Mill Part. Use the Guide as an aid to help you make good design choices for your own DIY CNC Milling Machine project.

Probably the most imporatant part of the CNC Machine and the most challenging to implement. I will try to make it easy for you by offering the common component that can be used in your DIY CNC Router. These parts are especially selected to work with motors used in the DIY community and took me quite a while to find the perfect combinations.For three months I tried to find the proper parts (A dremeltool, drawer slides, pieces of wood, etc.), but I didn't really know how to build a CNC. The idea fell into oblivion. In August 2013 the idea to build a CNC milling machine captivated me again. Here’s a cutaway of a cartridge spindle set up for ATC (Automatic Tool Changer) so you can get an idea of the components: CNC ATC Cartridge Spindle. Let’s go over the role of each component: Angular Contact Bearings: This particular spindle has two angular contact bearings plus two deep groove ball bearings (salmon colored).IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only .

For the DIY CNC router, mill, lathe, or robot! Only top-quality components from major manufacturers. Drive 3 or 4 steppers at up to 3 amps each. Since 1999, HobbyCNC has been selling a variety of high-quality DIY hobby CNC products: Stepper motor controller kits, DIY CNC router plans and stepper motors for the desktop machinist and DIY hobbyist.Building your own DIY CNC milling machine is a challenging but rewarding project that will give you the freedom to create custom metal parts with precision and efficiency. With our step-by-step guide, you'll have the knowledge and confidence to take on .First things first, buy and assemble a router. I bought the CNC 2417 Mini. There are lots of different models out there. Some of them come with a Laser module too. Just mind to pick one that matches these table slots, if you do not want to re-design my 3D parts. It's like lego, you see the picture and you build it.Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.

homemade cnc milling machine

diy desktop cnc mill

cnc cutting machine knife

diy cnc mill kit cost

Waterproof junction box with terminal strip for electronic connections in areas subject to spray, washdowns, etc. Rugged, non-corrosive polypropylene housing “Universal” cut-to-fit cable entries, diameter range: .14 -.81” Brass compression screw terminals; Wire gauge: 16 AWG

diy cnc mill parts|diy desktop cnc mill