3 axis cnc machine shop First and foremost, we would just like to add that this recommendation is strictly based on our reviews and may not be your preference. Second, we will break these down into two . See more If I have a junction box where there are splices from several circuits, do I connect all ground wires from all circuits together in one bundle or do I do that for each circuit within the junction box?

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

Below is our best attempt to capture all of the standard gauge thickness of different .

Having your CNC machine breakdown or a tool crash in the middle of an important job is enough to keep any shop owner up at night. With these thoughts in mind, it’s important to have a . See moreNow that we’ve covered what we like and don’t like about these CNC machines, let’s cover some of the other most important factors when buying . See more

First and foremost, we would just like to add that this recommendation is strictly based on our reviews and may not be your preference. Second, we will break these down into two . See more

wholesale aluminium cnc turned parts

We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes. Xometry offers instant pricing, on-demand lead times, and design-for . Ready to start your own machine shop, or just want to use a small CNC mill in your garage? With a plethora of budget CNC mill options in today’s market, it is not only difficult to make a decision but damn near impossible.We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes. Xometry offers instant pricing, on-demand lead times, and design-for-manufacturability feedback on materials and manufacturing processes for your custom CNC milled parts, no .The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove 30 pounds of steel per hour and the accuracy and precision to hold tight tolerances.

Miller CNC performs superior 3-axis machining services to meet or exceed your expectations. As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, Miller CNC can build fixtures that hold multiple parts to cut, all in one setup.

small 3 axis cnc mill

Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.

3-axis CNC machining delivers countless advantages. Below, we have mentioned some prominent benefits: Best for Simple Designs: It requires movement in just three directions – right-left, back-forth and up-down – these make it easier .MTCcorp utilizes Tebis for its NC Programming and simulations and continuous 5-axis machining operations and specializes in machining of metallics, composites, urethanes and glass. Working on a project? Request a quote today!

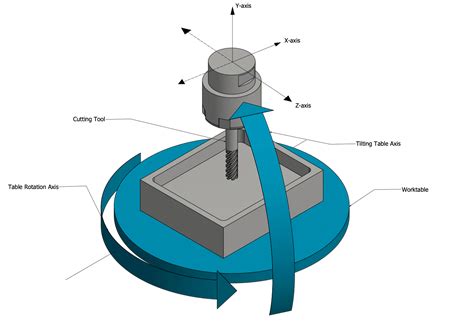

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe.

wholesale aluminum cnc machining parts factory

axis identification in cnc machine

3 axis vs 5 mill

whole house water filtration heavy metals

3 axis vertical milling machine

The metal sandwiched together on the bottom inside of the rocker panels, some of it is .060 and .040 thick, so when you're working different panels and braces, be aware you have different thickness's of sheet metal.

3 axis cnc machine shop|axis identification in cnc machine