solidworks bend non sheet metal part There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can . Alamont Home - Warner Modern Steel 3-Drawer Filing Cabinet - White. Color: White. Get previous slide. selected; Get next slide. Model: ALA-IZDI-442884. SKU: 6591792. Rating 4.3 out of 5 stars with 3 reviews (3) Compare. Save. $269.99 Your price for this item is $269.99. .

0 · solidworks sheet metal sketched bend

1 · solidworks sheet metal round bend

2 · solidworks sheet metal k factor

3 · solidworks sheet metal curved bend

4 · solidworks bend allowance table

5 · sketched bend in solidworks

6 · how to use sketched bend

7 · bend relief sheet metal solidworks

4-Pack Vintage Desktop Apothecary Cabinet w/ 3 Drawers - Wood Medicine Cabinet for Tabletop - Stackable Drawers w/Label Holders - Desktop Chest Drawer for Herb Storage, Tea Collection, Stationery

To remove every bent from a sheet metal component: Roll back the bends up to Sheet-Metal1 by clicking No Bends on the Sheet Metal toolbar. The bend allowance and radius are rolled back. .

There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can .I've been trying to bend a part with many features at an angle without changing its shape/consistency. I've tried Flex Tool but it turns into rounder shape when .

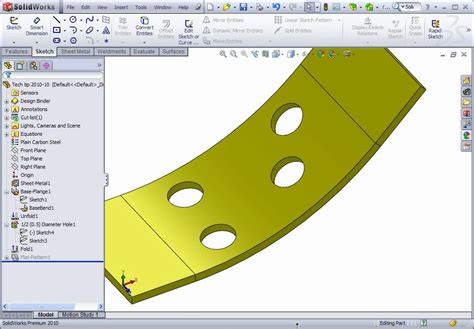

There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can . A quick tour and introduction using the SolidWorks Sheet Metal Sketch Bend Feature. In this video we will discuss how to take a thin metal part with a non-rectangular .

CreditSong: UTOPIA [Rewind Remix Release] Music provided by Rewind Remix: http://tinyurl.com/rewindremixArtists: HWNSOLIDWORKS 20162016年的SolidWorks2016 Nián .To create a sheet metal part with round bends: Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or Extruded . A sheet metal part is "initiated" with 3 consecutive features: Sheet-Metal1, Flatten-Bends1, Process-Bends1. (Feature names may vary slightly if renamed or redone.) Once all . i need some help about sheet metal in SolidWorks 2020. i have a sheet metal part and when going into the flat pattern, 1 bend says ''that this part contains a feature that cannot .

Hems don't like bend regions, and on this part the entire thing is a bend region. If you want a hem on the curved edge, I just tried it with a sketched bend and it works, you just have to sketch out the hem geometry in the profile. That will also allow it to flatten. If you want it on the flat edges, use Edge Flange and set the angle to close .

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. .ALL posts related to SOLIDWORKS are welcome. Share what you know. Learn what you don't. 100% Pirate Free Sub. Zero ToleranceThis separation is typically negligible for any sheet metal part, but not for SOLIDWORKS. Figure 6 Figure 6a . 12 7) Avoid Self-Intersection with Edge-Flange . Bend Allowances Calculation in Edge-Flanges on non-linear edges The bend allowance is calculated for the cylindrical bend and the bend between the main body and edge-flange feature .

This feature is available in all parts, not just sheet metal parts. You can use it in single bodies, multibodies, and parts in the context of an assembly. After you select the tab edge in a sheet metal part, SOLIDWORKS ® automatically selects a slot face that is normal to the edge to streamline the process. For non-sheet metal parts, you need .

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hi! Making a cone bend in sheet metal is a common problem, with many solutions presented here or at Youtube. . Then sharp bend 6. Finally flat, non-rectangular part I made this starting from a flat state (i.e. sketched the flattened shape) with sketched bends .Knowing the basic bend types will assist you in understanding the different ways to bend a part in SolidWorks. Sharp bends, round bends, and flat bends are the three types of bends that may be applied when converting a solid body to a sheet metal part using the Insert Bends or Convert to Sheet Metal tools.Flat pattern was made in the part, opening up that view in the sheet metal application shows bend notes. However, inserting the flat view in the drawing results in no bend notes being shown at all. I know the information exists in the drawing because adding a bend table shows the information just fine. Any help is appreciated, thanks!Sheet metal PropertyManagers help you create and modify sheet metal parts: Base Flange/Tab. A base flange is the first feature in a new sheet metal part. Insert Bends. Insert bends allows you to convert a shelled part to a sheet metal part. Bends PropertyManager. The Bends PropertyManager allows you to convert a shelled part to a sheet metal part.

Sheet metal PropertyManagers help you create and modify sheet metal parts: Base Flange/Tab. A base flange is the first feature in a new sheet metal part. Insert Bends. Insert bends allows you to convert a shelled part to a sheet metal part. Bends PropertyManager. The Bends PropertyManager allows you to convert a shelled part to a sheet metal part.Il sito non supporta il browser o la versione del browser in uno. Alcune funzioni potrebbero presentare un comportamento imprevisto. . files. For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part. . In the SOLIDWORKS to DXF/DWG . Sheet metal faces being non-planar is the most common issue that prevents an edge from being selected for an edge-flange. . This occurs because SOLIDWORKS uses gauge tables, bend deduction, K-factors, etc. to properly simulate the dimensions of the part in both the flattened and formed states. . boss-extrudes that aren't linked to the .

metal piers for housing

Use insert bends and select one of the straight edges as the fixed edge. This part is a cone though so a simple conversion isn't going to work. The way I would do this is to use the imported geometry as a reference to make a native sheet metal part using lofted bend.When you create a part initially out of sheet metal you can use the Base Flange tool with an open or closed profile sketch. This eliminates extra steps because you create a part as sheet metal from the initial design stage. Build a part, shell it, and then insert sheet metal bends. If you build a solid using non-sheet metal features, you need .Sheet Metal Part Won't Flatten I finally got my lofted bend to work between my two arc profiles, but now I cannot create a flat pattern from it. I'm not sure if it's the nature of the bends, or something else like a bend allowance that is making it .This cannot directly make a conic bend though. You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone).

To convert an imported model into a sheet metal part, FeatureWorks uses the SOLIDWORKS API. If this API fails, FeatureWorks does not recognize the miter flange. To check if the API is working, open the imported part in SOLIDWORKS and click Insert > Sheet Metal > Bends. If the operation fails, miter recognition also fails.I have a part that I am trying to get the flat pattern for, when I do the flat pattern Edge Flange 1 will not unbend (it is a 30° bend). If I change it to a 45° bend it will flatten. I cannot figure this out. EDIT SOLVED It was an issue with the bend radius and Bend deduction. CreditSong: UTOPIA [Rewind Remix Release] Music provided by Rewind Remix: http://tinyurl.com/rewindremixArtists: HWNSOLIDWORKS 20162016年的SolidWorks2016 Nián .

For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part. To export and map bend line directions for a sheet metal part: . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. You can create a rip feature: Along selected internal or external model edges . you can flatten the part as sheet metal. (SOLIDWORKS supports straight cuts only .For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of .

geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude,Creating Sheet Metal Parts with Conical Faces. Parts with conical faces can also be made of sheet metal. Converting a Shelled Solid Body to a Sheet Metal Part. It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. Sheet Metal Features. When you click Insert Bends on the Sheet Metal .Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model .Select Ignore beveled faces to exclude chamfers from being converted into sheet metal bends. Under Bend Allowance, select from the following bend allowance options: Bend Table, K-Factor, Bend Allowance, Bend Deduction or Bend Calculation. If creating a sheet metal part with one or more conical faces, you must . Oblong or non-right angle cones .

You can calculate the developed length of sheet metal parts using bend calculation tables. Editing the Default Bend Radius, Bend Allowance, Bend Deduction, or Relief Type. A Sheet-Metal1 feature in the FeatureManager design tree indicates a sheet metal part. The Sheet-Metal1 feature contains the default bend parameters.

solidworks sheet metal sketched bend

The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. These early servomechanisms were rapidly augmented with analog and digital computers, creating the modern CNC machine tools that have revolutionized the .

solidworks bend non sheet metal part|bend relief sheet metal solidworks