solidworks convert rolled part to sheet metal By far, the most common way to purchase metals for end use is as “sheet metal”, which is defined as a flat metal less than ¼” thick (about 3 gauge) and going all the way down to as thin as 0.0125” (or 30 gauge). Sheet metal can be bent, rolled, formed, stamped, slit, spun and generally fashioned into just . See more Whether you plan to use it on your home or an outbuilding, we’re going to go through the steps of installing steel siding: specifically vertical siding. There are several reasons people have been choosing to install steel siding on their homes instead of the basic asphalt or wood, for example.

0 · solidworks sheet metal tutorial pdf

1 · solidworks sheet metal pdf

2 · solidworks sheet metal part drawing

3 · solidworks sheet metal guide

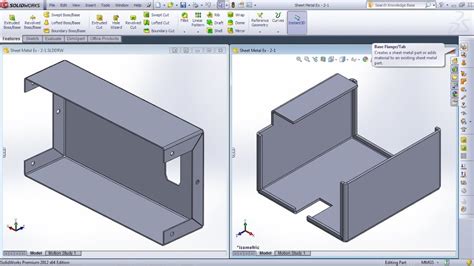

4 · solidworks sheet metal examples

5 · solidworks sheet metal cylinder

6 · folding sheet metal in solidworks

7 · auto relief solidworks sheet metal

300 Cubic Feet Per Minute. Under Cabinet Mount. Stainless Steel. wall mount liner. Batteries Required? No. Amazon.com Return Policy: Amazon.com Voluntary 30-Day Return Guarantee: You can return many items you have purchased within 30 days following delivery of the item to you.

solidworks sheet metal tutorial pdf

By far, the most common way to purchase metals for end use is as “sheet metal”, which is defined as a flat metal less than ¼” thick (about 3 gauge) and going all the way down to as thin as 0.0125” (or 30 gauge). Sheet metal can be bent, rolled, formed, stamped, slit, spun and generally fashioned into just . See moreRolled and welded tube and pipe are by far the most common application for rolled sheet metal, but there are other advantages: 1. Cost: . See more

solidworks sheet metal pdf

Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. See more

Using this method means the rolled part features can include holes, edge profiles, or other complex shapes, allowing much faster fabrication, tight fitment without any modification, and no . See more

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. To convert a solid part to a sheet metal part: .

You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .

Converting a Solid Part to a Sheet Metal Part. The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. .The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. To convert a solid part to a sheet metal part: .

SOLIDWORKS offers a simple conversion tool that allows you to modify your part into a sheet metal design with rips, bends, and flat patterns efficiently. Make sure to watch the .

solidworks sheet metal part drawing

Follow along as we break down the steps, providing clear instructions and helpful tips to seamlessly transform your solid parts into efficient sheet metal components. Whether you're new. “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part . This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. Learn how to convert a solid part and surface body parts into sheet metal. Explore our library of SOLIDWORKS tutorials today: https://www.solidprofessor.com/.

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.Under Sheet Metal Parameters: Select a face as the fixed face for the sheet metal part. Set the sheet thickness and default bend radius. Select Keep body if you want to keep the solid body to use in another Convert to Sheet Metal feature. When cleared, the body is consumed by the Convert to Sheet Metal feature.You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone).

I'm trying to convert a mitered pipe segment piece into a sheet metal part that can be flattened then plasma-cut and rolled. The shop drawing calls for small sections of pipe to be cut width-wise then mitered both ways (see attachment).

https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials.we will learn sketch,sheet .

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .I’ve tried a few methods and SolidWorks always seems to stumble into something. I’m trying to convert this shape into Sheet Metal so I can flat pattern it and make a drawing. It’s essentially an Ellipse that’s been cut in half at a 45 degree angle. Extruded to 100mm and the piece itself is .I understand that the traditional way to convert a cylindrical part to sheet metal is by starting with a semi circle that has a break in it, then convert it from there. Problem is I'm trying to transfer some old SolidWorks drawings that someone else printed, and that the only drawings that were available for these were the flattened version .Other than you having problems converting is to sheet metal, this part can not be manufactured out of a single sheet. tube like the bottom part aren't bend with a press but rolled. Top part are way too long flanges to bend, will hit the tools of the press.

You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. The imported part must be a constant thickness. If the part you are converting has a formed feature, the formed feature is deleted. You can reapply the feature after the conversion.By using the Base Flange/Tab, create a circle with a small gap in it. That gap is for the cut on the sheet to make it possible to roll in a cylinder form. After that you just add your thickness and bend radius. If you can use your flatten view then you know the sheet has a correct bend in it. Checkout our free inar for SolidWorks Beginners

Solidworks can't convert compound bends (where are bend is being bent in another direction) but you can do them as a native sheet metal part. The easiest way is to make the bottom of the channel as a base/flange tab then use edge flange features for the legs.Learn about this tip for those who use #SOLIDWORKS sheet metal. You probably, normally, come across a sketch and pull-edge type of flange to create sheet met.Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body .You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. The imported part must be a constant thickness. If the part you are converting has a formed feature, the formed feature is deleted. You can reapply the feature after the conversion.

sigma electric 1-gang rectangle metal weatherproof electrical box cover

Last updated on January 15th, 2024 at 12:23 pm. Converting a solid part to a sheet metal part in software like SOLIDWORKS is important for several reasons:. Material Efficiency: Sheet metal parts are typically designed .

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. The software automatically selects the edges on which rips are applied.You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. The imported part must be a constant thickness. If the part you are converting has a formed feature, the formed feature is deleted. You can reapply the feature after the conversion.

Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body .

solidworks sheet metal guide

Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body .To add a body to a sheet metal part using Convert to Sheet Metal: In a sheet metal part, select or create a plane and draw a sketch. Extrude the sketch. Click Convert to Sheet Metal (Sheet Metal toolbar) . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

solidworks sheet metal examples

Exercise 23 - Cylindrical Sheet Metal parts, Linear sketch patternsGood morning! I have this part that I'm trying to convert to sheet metal, a rolled open profile that will likely be formed on a rod in a press brake with a suitable special bottom die. I can get the surface created but not any swept profiles that will flatten. The thickness is .049 if that helps and I would use a K factor of .5 Amazing workaround for sheet metal parts with intentional interference (think spring clips).If you know how to convert to sheetmetal the first feature I would be very grateful to listen to how :-) Thank you Raúl . Cutout over a curved sheet metal part. RB By Raul Borobio 03/13/15. Hello. How would you design this part? I need a perfect d=10.2 mm circle. I made a d=1mm cutout over the rolled sheet metal, unfold, cutout a d=10,2 mm .

I'm trying to convert a shelled part to sheetmetal. The part has some large radius curves that I want to be rolled out of 2mm. First I generally add some split lines where I want parts separated. I can convert from the inside of the part or outside, either way, I'm not picky. Inside gives me perfectly corner to corner parts, which is nice.Under Sheet Metal Parameters: Select a face as the fixed face for the sheet metal part. Set the sheet thickness and default bend radius. Select Keep body if you want to keep the solid body to use in another Convert to Sheet Metal feature. When cleared, the body is consumed by the Convert to Sheet Metal feature.

solidworks sheet metal cylinder

Hold Down Brackets for 25mm Venetian Blinds (Pack of 2) £3.00 (1) Compare. Quick View. Pair of Metal Valance Clips/Pelmet Brackets for Wood/Sunwood Blinds. £2.95. Compare. Quick View. Slat Top Clip for 35mm Wood Venetian .

solidworks convert rolled part to sheet metal|solidworks sheet metal cylinder