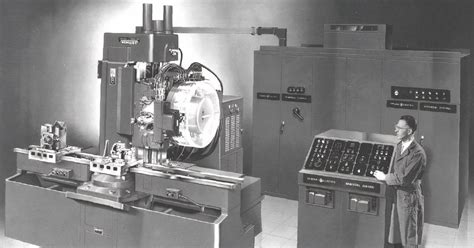

evolution of cnc machines The evolution of CNC machines transformed manufacturing by making the production of very complex parts possible. The roots of CNC machining can be traced back to the 1940s and 1950s with the development of .

Vintage tackle boxes are an angler’s best friend, the key to keeping their favorite spinners, plugs, minnows, and other lures from getting tangled with spare spools of fishing line, extra reels, floats, and invaluable hand tools.

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · when did cnc machining start

3 · history of cnc machining

4 · history of cnc machine pdf

5 · first cnc milling machine

6 · cnc router history

7 · cnc machine history timeline

$80.00

who invented the cnc machine

This article explores the history of CNC machines, tracing their evolution from early numerical control systems to the advanced CNC technologies we see today, and highlights how these .CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots .

when were cnc machines invented

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to .

CNC machines have evolved from simple, punch-tape-controlled devices into almost fully automated apparatuses capable of working using numerous axes. For anyone who works with this equipment, the story of how .

The evolution of CNC machines has been nothing short of remarkable. From the early days of numerical control to the advanced systems we have today, these machines have transformed .

The evolution of CNC machines transformed manufacturing by making the production of very complex parts possible. The roots of CNC machining can be traced back to the 1940s and 1950s with the development of .

From the early days of hand-crafted products to the modern era of computer-controlled machines, CNC machining has come a long way. In this article, we’ll explore the evolution of CNC machining from the past to the .Our unwavering commitment to pushing the boundaries of CNC technology persists. We are dedicated to providing cutting-edge solutions that not only meet but surpass the rigorous demands of the semiconductor sector. Home Role of .

History and Evolution: CNC machines have been crucial in the semiconductor industry since the 1980s, enabling the production of increasingly smaller and more complex microchips. The evolution of CNC technology has kept pace with the miniaturization of semiconductor components, allowing manufacturers to meet the demands of modern electronics. .

when did cnc machining start

The History & Evolution of Precision Manufacturing & CNC Machining . However, modern CNC machines can handle a level of complexity that simply would not have been possible even a couple of decades ago. For .The journey of CNC (Computer Numerical Control) machining from its inception to the present day is a testament to the leaps and bounds by which technology has transformed manufacturing. CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical [.]CNC machining has revolutionized the manufacturing industry, allowing for unprecedented precision and automation. But this technology didn't appear overnight. The history of CNC machining is a long and fascinating one, filled with key developments and breakthroughs that have helped shape modern engineering and design. Whether you're a mechanical engineer, .From their early prototypes to their current state-of-the-art iterations, CNC machines have undergone a remarkable evolution in a relatively short amount of time. Thanks to advancements in computer technology, automation, and materials science, these machines have become essential tools for modern manufacturing.

In conclusion, CNC machines have come a long way since their inception. They have become essential tools for manufacturers across varying industries, enabling improved precision and consistency in part production. Advancements in technology have only made CNC machining increasingly popular, with new and improved machines constantly developed .CNC machines, also known as computerized milling machines, are automated tools controlled by a computer program. These machines use pre-programmed instructions to precisely control the movement of cutting tools, resulting in accurate and repeatable shapes and sizes. II. The Emergence of CNC Machines in Gun Manufacturing: Before we delve into the evolution of CNC machining, it’s essential to understand what CNC machining is. CNC machining stands for Computer Numerical Control, which means that the manufacturing process is automated and controlled by a computer program. It involves the use of computer-controlled machines to cut, shape, and form metal, plastic .

This article explores CNC machining's evolution, the various processes involved, its applications across industries, and future manufacturing projections for the 2030s. Introduction to CNC Machining. CNC machining refers to the automated control of machining tools via a computer, allowing for high precision and efficiency in manufacturing .

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the .

Explore the fascinating evolution of machining, from its ancient origins to the technological advancements of today. . CNC machines are the backbone of modern machining, allowing for precise and repeatable production of complex parts. These machines are used in various industries, including aerospace, automotive, and medical devices.CNC Machines (1454) CNC Mill (803) CNC Lathe (500) Vertical Machining Center (648) Horizontal Machining Center (142) Boring Mill (13) Router (112) EDM (21) Manual and Other Machining . The evolution from traditional manufacturing robots to modern cobots marks a significant milestone in the manufacturing industry. Cobots bring a new level of . Taking common turning and milling as an example, the evolution of a typical CNC machine tool structure is shown in Figure 3. CNC turning machine structure from the early 2-axis feed flat bed, 2-axis feed slant bed, and other classic structures, to 4-axis feed and double tool holder, multi-spindle and multi-tool holder for rotary parts such as . In the machining process of computer numerical control (CNC) machine tools, both dynamic and static errors significantly impact the machining accuracy. The ability to accurately estimate the machining quality of products in real time is of great significance for the closed-loop control of machining accuracy of CNC machine tools. For this purpose, this paper .

A customer with multiple LICO multi-slide CNC machines had a particular part that was running 8.5 seconds on their Acme screw machines. Absolute performed a time study, set the machine up in our showroom, and .As computing technology advanced, CNC systems evolved from punch-card readers to more sophisticated computer interfaces. The 1970s saw the adoption of microprocessors, which improved the processing speed and capabilities of CNC machines. This led to increased precision, complexity, and versatility in machining operations.

Explore the fascinating evolution of CNC machining in our comprehensive blog post. Delve into its historical roots, significant technological advancements, and impact across various industries. Discover how CNC machining has transformed modern manufacturing, shaping the future with innovations in automation, AI, and precision engineering.Moreover, CNC machines offer the flexibility to produce customized parts, enabling firearm enthusiasts to personalize their AR-15 rifles to their preferences. 4. CNC Machining Techniques for AR-15 Rifles . Various CNC machining techniques are employed in the production of AR-15 rifles. These techniques include milling, turning, drilling, and .Check out our articles, news and reviews covering all aspects of CNC Machines, including CNC mills, lathes, top brands, materials, and precision engineering. Rapid Results AI. Login / Signup. CNC Machines (1441) CNC Mill (798) Vertical Machining Center . The Evolution of CNC Technology: A Historical Perspective. Explore the history of CNC .Join us on a journey through time as we uncover the milestones and innovations that have shaped the evolution of CNC machines. Section 1: The Origins of CNC Machines\ In this section, we will delve into the early days of numerical control and how it laid the foundation for CNC machines. We will discuss the key pioneers and their contributions .

pneumatic sheet metal hole punch

In this blog post, we will dive into the history and evolution of CNC machines, exploring their early origins, key innovations, and the impact they have had on various industries. I. The Early Days of CNC Machines (200-500 words) . Automotive Industry: CNC machines have played a crucial role in the automotive industry, enabling the production .

From its humble beginnings to today's sophisticated systems, CNC machines have not only streamlined production processes, but also enabled creative design. In this article, we will explore the evolution of CNC technology, how it has shaped various industries, and what the future may hold for this game-changing technology. . The evolution of . This work, entirely based on a documental research strategy, consists of an analysis of the technological evolution of the machining processes with Computer Numerical Control machines regarding .

This article traces the evolution of CNC machines in Malaysia and underscores their significance in the nation's growth story. Initial Forays into Automation: The 1980s. The 1980s marked Malaysia's aggressive pivot towards industrialization. The national ambition to shift from an agrarian economy saw the inception of various manufacturing .

history of cnc machining

In this blog post, we will explore the evolution of Hurco CNC machines and how they have reshaped the manufacturing landscape. History of Hurco CNC Machines: Hurco was founded in 1968 by Gerald Roch and Edward Humston as an outgrowth of the Burke Porter Machine Tool Company. Their goal was to create CNC machines that would simplify the .The evolution of CNC machines from punch cards to the sophisticated systems of today represents a remarkable journey of innovation and technological advancement. CNC machines have significantly transformed manufacturing processes, enabling greater precision, efficiency, and versatility. As we look to the future, the integration of AI .

history of cnc machine pdf

first cnc milling machine

Check out our vintage green metal bread box selection for the very best in unique or custom, handmade pieces from our kitchen storage shops.

evolution of cnc machines|when were cnc machines invented