anodized aluminum oxide template fabrication We present an overview of theories on the formation of pores and self-ordering in alumina, paying special attention to those presented in recent years, and different nanostructures that have .

Fabrication of metal has three main phases, design, fabrication, and installation. This process adds value to raw metal, transforming it into usable products and components. .

0 · multipore anodized aluminium oxide template

1 · anodizing aluminum

2 · anodized aluminum oxide template

3 · anodized aluminum oxide

4 · anodized alumina model

5 · anodized alumina fabrication process

6 · anodic aluminum oxide design template

7 · anodic aluminum oxide design

Metallic fabrics are fabrics that incorporate metallic elements - characteristics, uses, and unique qualities of metallic fabrics, such as metallic brocade, lamé, sequins, lurex, and metallic-coated fabrics.

Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore .We would like to show you a description here but the site won’t allow us.

We would like to show you a description here but the site won’t allow us. In this work, we have fabricated multipore (binary, ternary and quadruple) templates using imprinted anodized aluminium oxide templates and demonstrated good control in terms of size,.

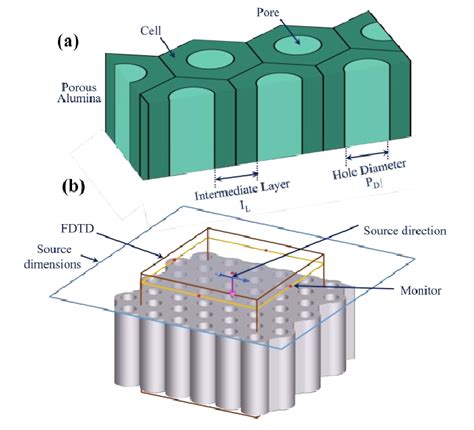

The anodic aluminum oxide (AAO) template is the perfect mold because it offers many desired qualities, such as adjustable pore diameters, high mechanical properties, and .We present an overview of theories on the formation of pores and self-ordering in alumina, paying special attention to those presented in recent years, and different nanostructures that have .anodic aluminium oxide is insoluble, are used. Then, under a certain applied voltage, an insulator oxide barrier layer is formed. In brief, the process involves the migration of oxygen-containing . Nanoporous anodic aluminum oxide (AAO) is an important template for 1D nanomaterial synthesis. It is used as an etching template for nanopattern transfer in a variety of contexts, including nanostructured material .

Properties of AAO, like pore diameter, interpore distance, wall thickness, and anodized aluminum layer thickness, can be fully controlled by fabrication conditions, including .

Anodic aluminum oxide is a widely applied template material for nanofabrication. To prepare a suitable template, a posttreatment of AAO formed after the second step of .

Thick ordered anodized aluminum oxide (AAO) templates can be fabricated by a two-step oxidation process. By strictly controlling temperature and voltage parameters, high . Anodic aluminum oxide (AAO) templates are widely used for the development of various functional nanomaterials due to their highly ordered and tunable porous structures. Here, we report a new hierarchical AAO (hAAO) . Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore combinations. In this work, we have fabricated multipore (binary, ternary and quadruple) templates using imprinted anodized aluminium oxide templates and demonstrated good control in terms of size,.

The anodic aluminum oxide (AAO) template is the perfect mold because it offers many desired qualities, such as adjustable pore diameters, high mechanical properties, and good thermal stability. Moreover, the AAO template serves as a valuable tool for creating anodic aluminum oxide.We present an overview of theories on the formation of pores and self-ordering in alumina, paying special attention to those presented in recent years, and different nanostructures that have been developed recently.anodic aluminium oxide is insoluble, are used. Then, under a certain applied voltage, an insulator oxide barrier layer is formed. In brief, the process involves the migration of oxygen-containing ions (O2 −and OH ) into the metal from the metal-oxide interface, while the metal ions can either form an oxide layer or be released to the electrolyte. Nanoporous anodic aluminum oxide (AAO) is an important template for 1D nanomaterial synthesis. It is used as an etching template for nanopattern transfer in a variety of contexts, including nanostructured material synthesis, electrical sensors, optical sensors, photonic and electronic devices, photocatalysis, and hardness and anticorrosion .

Properties of AAO, like pore diameter, interpore distance, wall thickness, and anodized aluminum layer thickness, can be fully controlled by fabrication conditions, including electrolyte,. Anodic aluminum oxide is a widely applied template material for nanofabrication. To prepare a suitable template, a posttreatment of AAO formed after the second step of anodization is required. Firstly, the remaining, unoxidized aluminum has to be removed (Fig. 17 ). Thick ordered anodized aluminum oxide (AAO) templates can be fabricated by a two-step oxidation process. By strictly controlling temperature and voltage parameters, high-quality films 140 to 188 μm thick can be realized.

Anodic aluminum oxide (AAO) templates are widely used for the development of various functional nanomaterials due to their highly ordered and tunable porous structures. Here, we report a new hierarchical AAO (hAAO) template with the hexagonally ordered unit cells and the radially distributed nanochannels. Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore combinations. In this work, we have fabricated multipore (binary, ternary and quadruple) templates using imprinted anodized aluminium oxide templates and demonstrated good control in terms of size,.

The anodic aluminum oxide (AAO) template is the perfect mold because it offers many desired qualities, such as adjustable pore diameters, high mechanical properties, and good thermal stability. Moreover, the AAO template serves as a valuable tool for creating anodic aluminum oxide.We present an overview of theories on the formation of pores and self-ordering in alumina, paying special attention to those presented in recent years, and different nanostructures that have been developed recently.

multipore anodized aluminium oxide template

anodizing aluminum

anodic aluminium oxide is insoluble, are used. Then, under a certain applied voltage, an insulator oxide barrier layer is formed. In brief, the process involves the migration of oxygen-containing ions (O2 −and OH ) into the metal from the metal-oxide interface, while the metal ions can either form an oxide layer or be released to the electrolyte.

Nanoporous anodic aluminum oxide (AAO) is an important template for 1D nanomaterial synthesis. It is used as an etching template for nanopattern transfer in a variety of contexts, including nanostructured material synthesis, electrical sensors, optical sensors, photonic and electronic devices, photocatalysis, and hardness and anticorrosion . Properties of AAO, like pore diameter, interpore distance, wall thickness, and anodized aluminum layer thickness, can be fully controlled by fabrication conditions, including electrolyte,.

anodized aluminum oxide template

Anodic aluminum oxide is a widely applied template material for nanofabrication. To prepare a suitable template, a posttreatment of AAO formed after the second step of anodization is required. Firstly, the remaining, unoxidized aluminum has to be removed (Fig. 17 ).

anodized aluminum oxide

Thick ordered anodized aluminum oxide (AAO) templates can be fabricated by a two-step oxidation process. By strictly controlling temperature and voltage parameters, high-quality films 140 to 188 μm thick can be realized.

anodized alumina model

When it comes to auto body repair, the choice of sheet metal gauge is important for ensuring structural integrity and performance. For aluminum panels, gauges typically range .

anodized aluminum oxide template fabrication|anodized alumina model